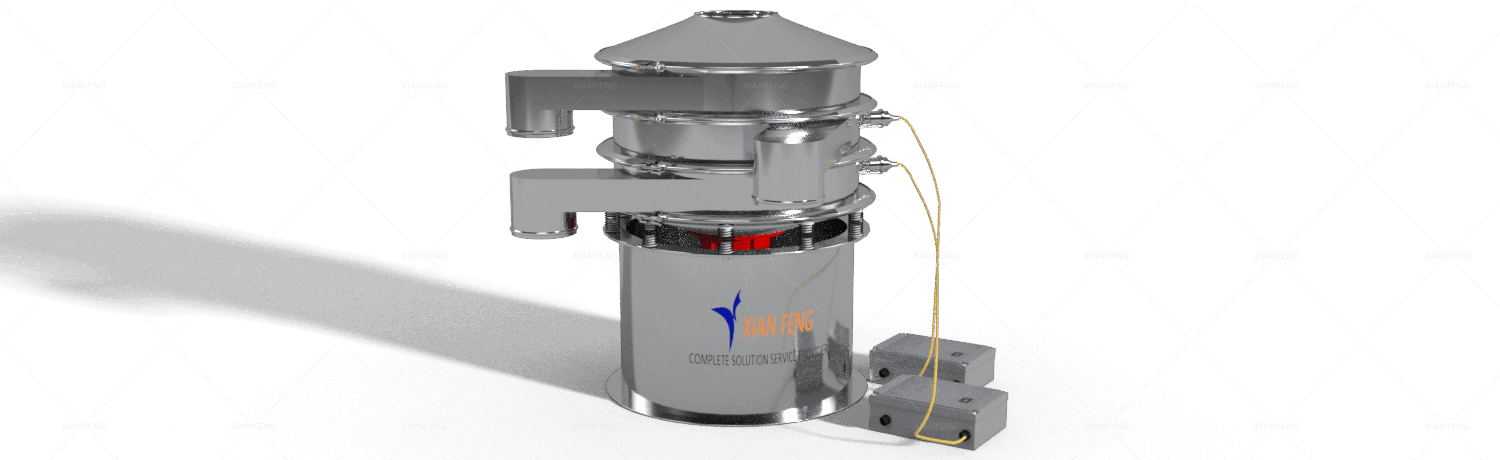

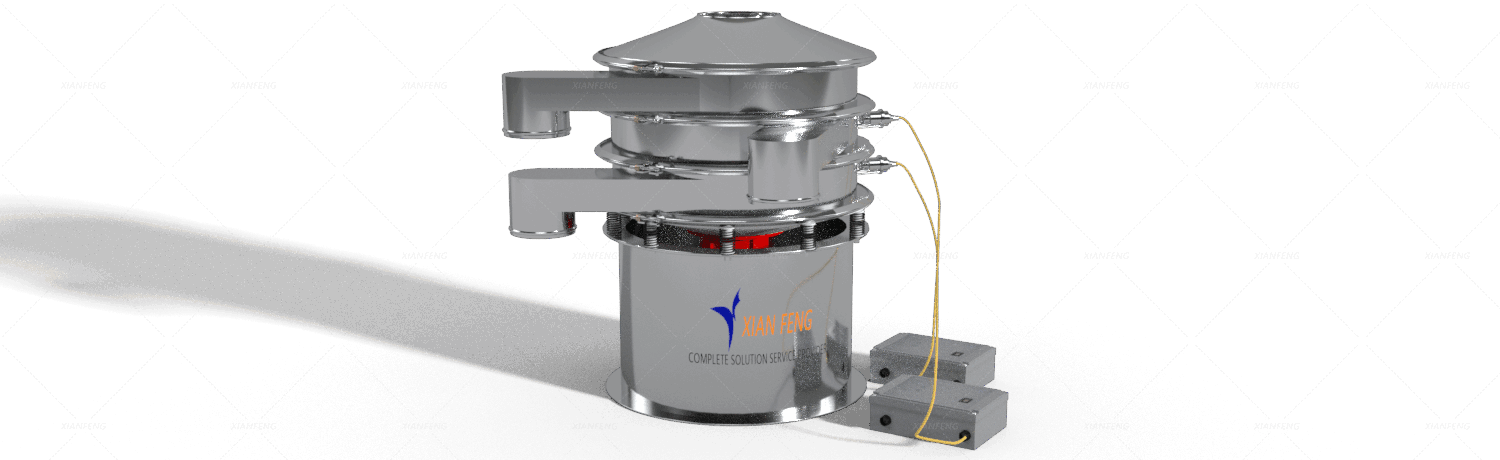

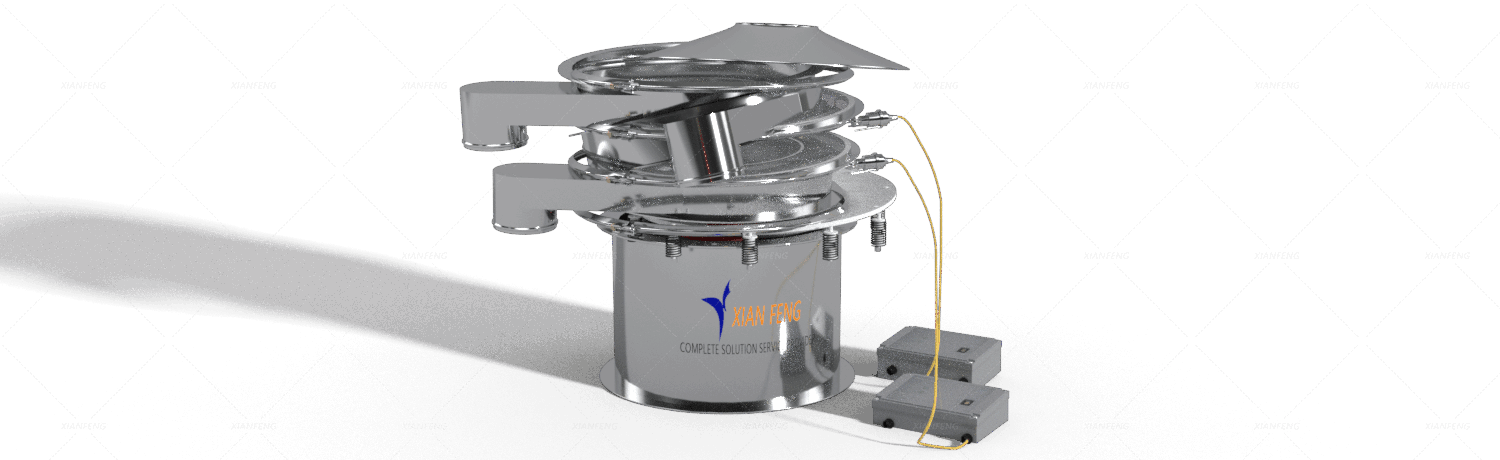

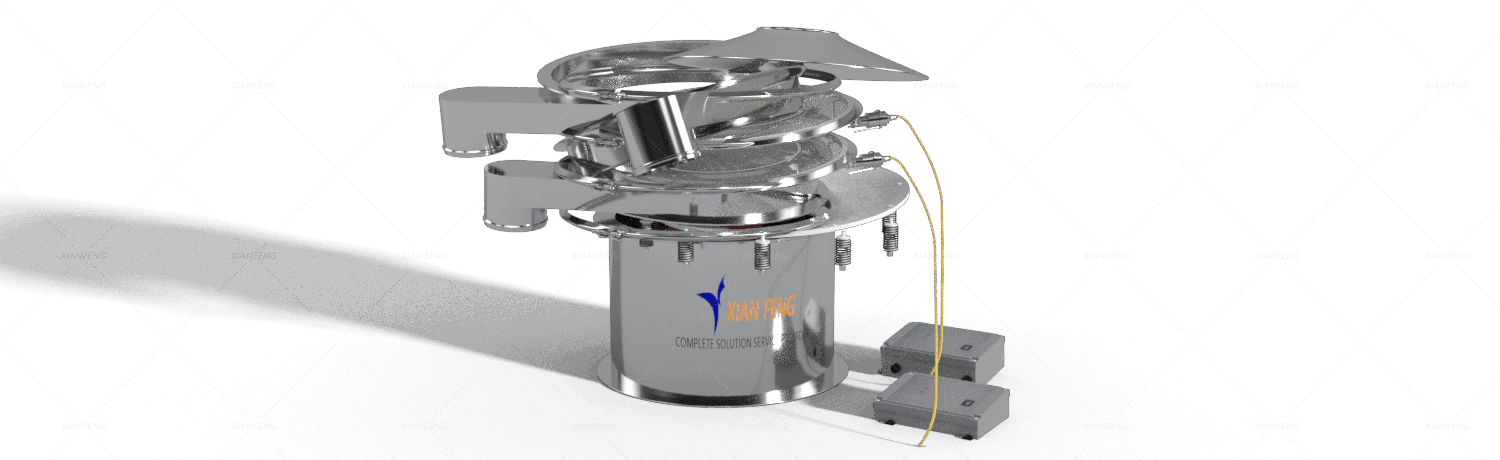

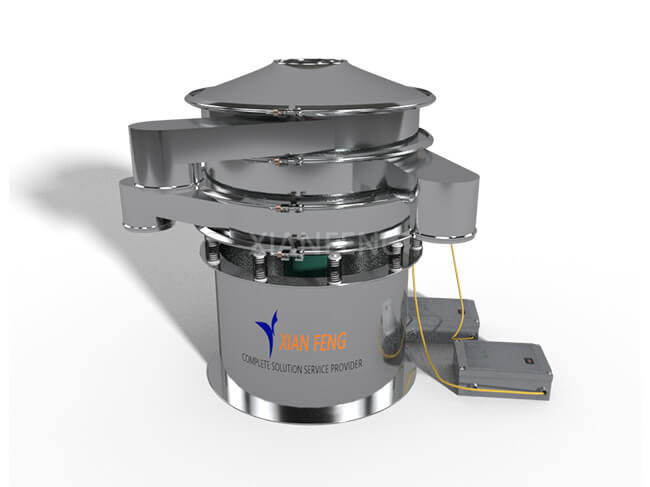

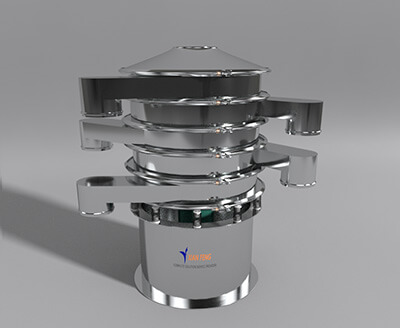

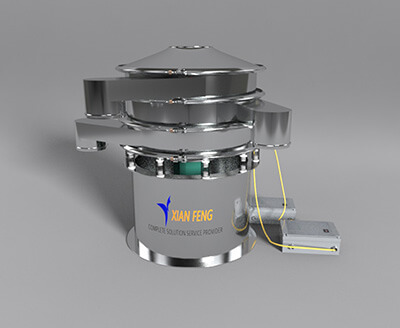

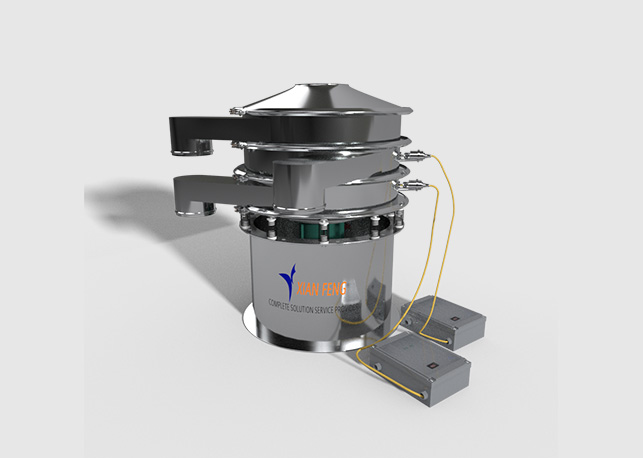

Ultrasonic vibrating screen is a specialized fine screening machine for fine powders. It is based on a circular vibrating screen separator, with the addition of an ultrasonic controller and a mesh system. It is used for screening materials with a mesh size of 200 or more that are difficult to pass through or prone to clogging. It has a wide range of applications and can be used in various industries. It is a multifunctional and customizable vibrating screen with anti clogging and anti-static features.

starch, powdered sugar, milk powder, salt, protein powder, seasoning, food additives, etc.

epoxy resin, catalysts, coatings, soda ash, baking soda, etc.

iron powder, aluminum powder, nickel powder, titanium powder, aluminum oxide, silicon carbide, ferrite powder, etc.

Western medicine powder, traditional Chinese medicine powder, pharmaceutical intermediates, formulation raw materials, probiotics, pearl powder, etc.

calcium carbonate, quartz sand, lime, gypsum powder, cement, glass microspheres, etc.

silicon carbide, alloy powder, molybdenum powder, carbon powder, electromagnetic powder, laser powder, molybdenum powder, graphite powder, etc.

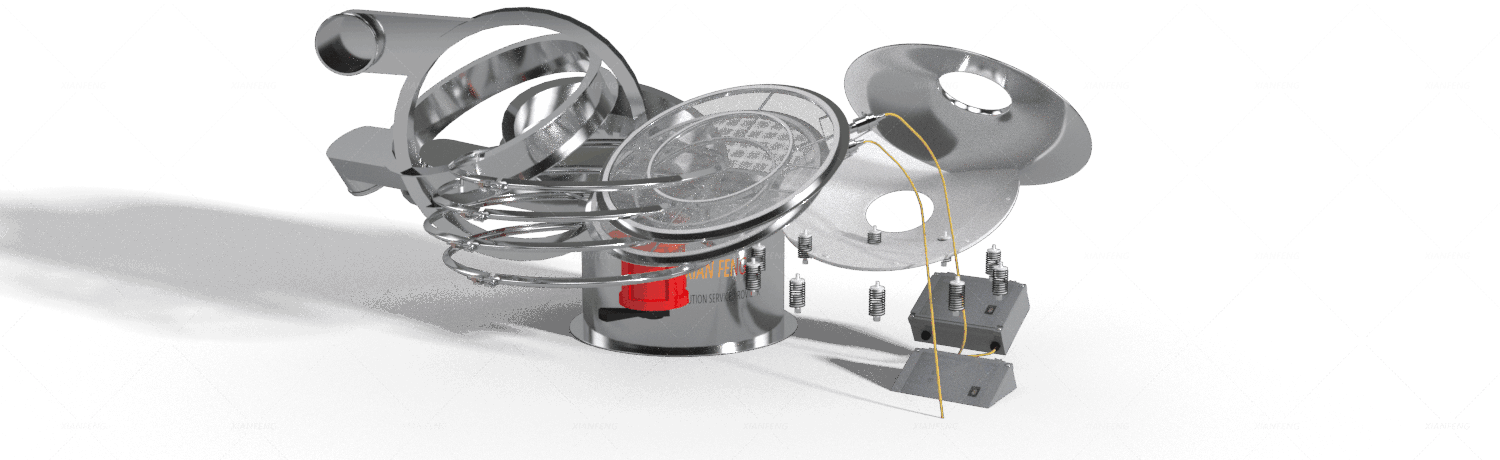

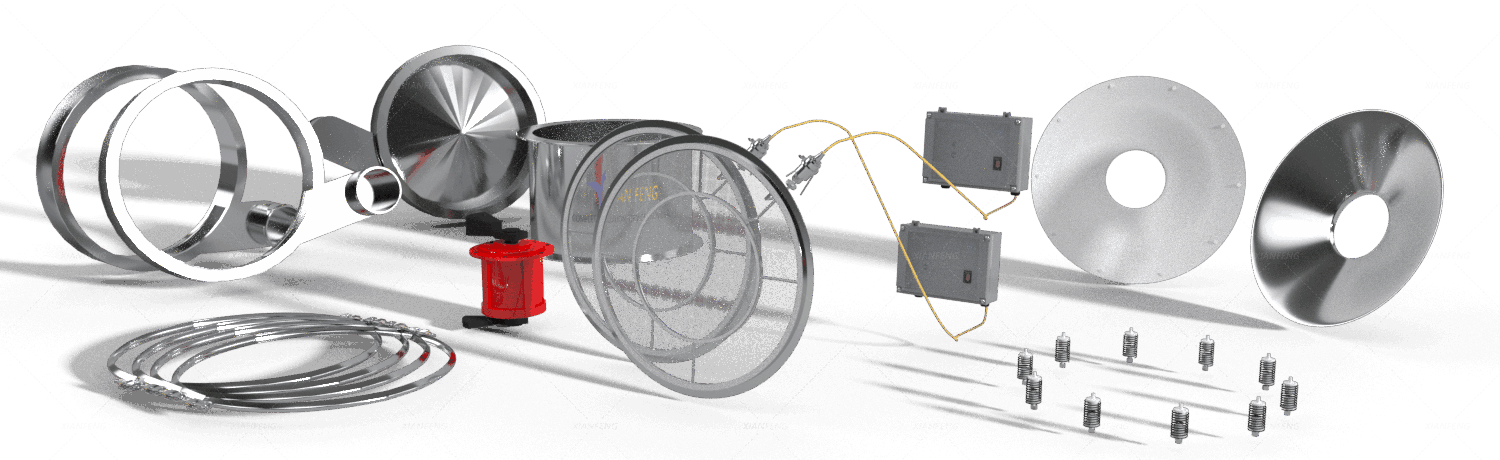

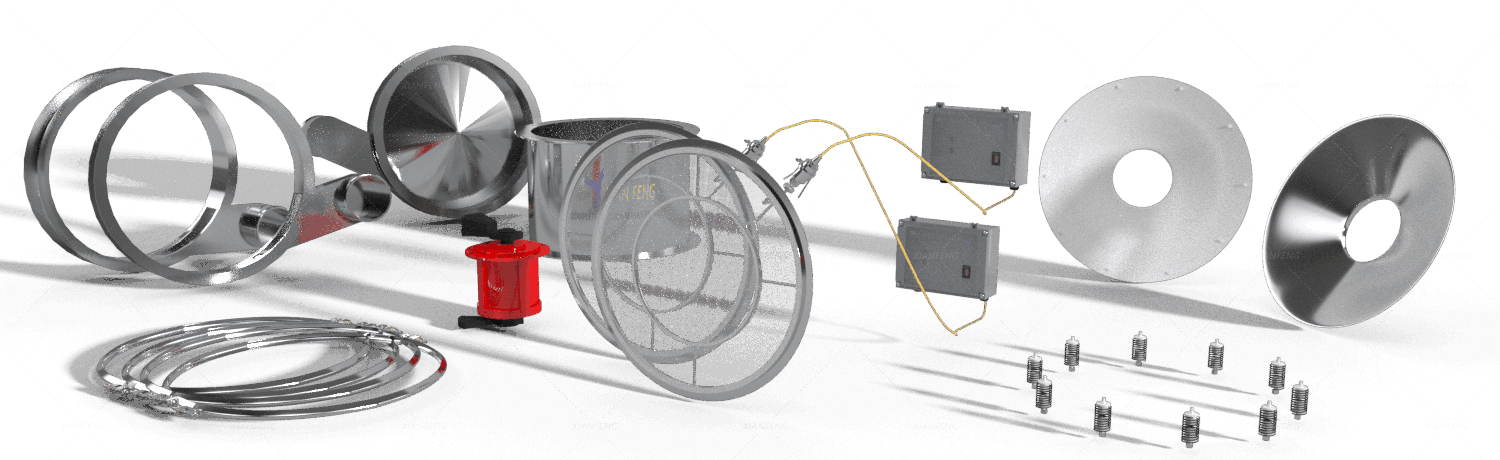

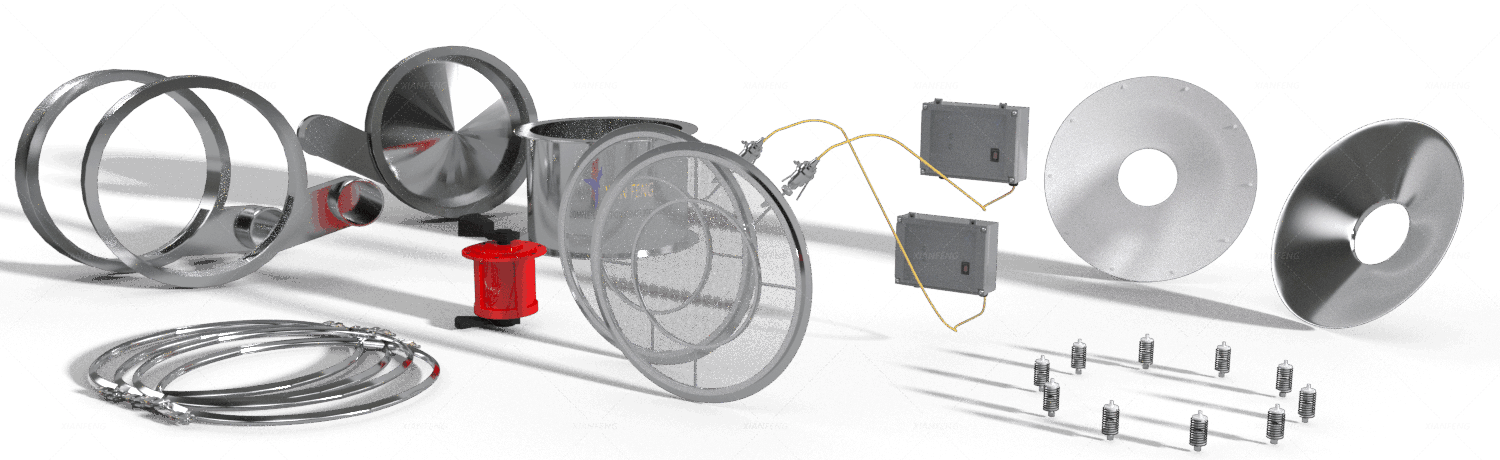

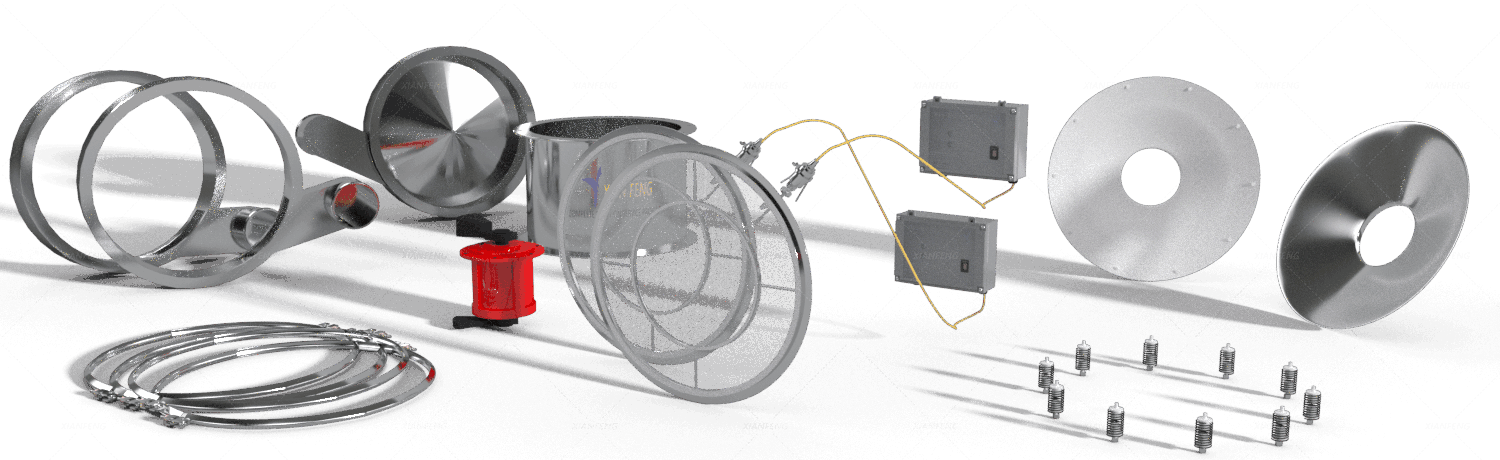

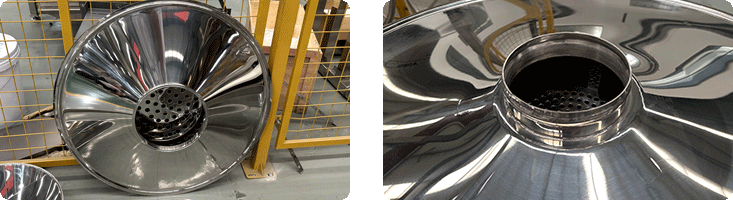

feed inlet

customize

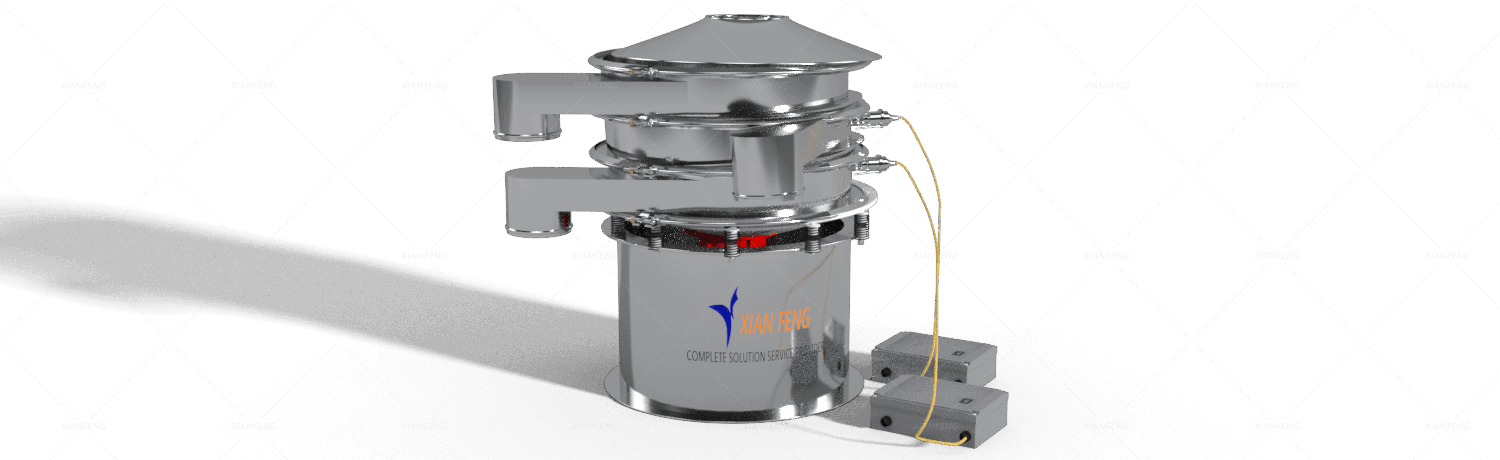

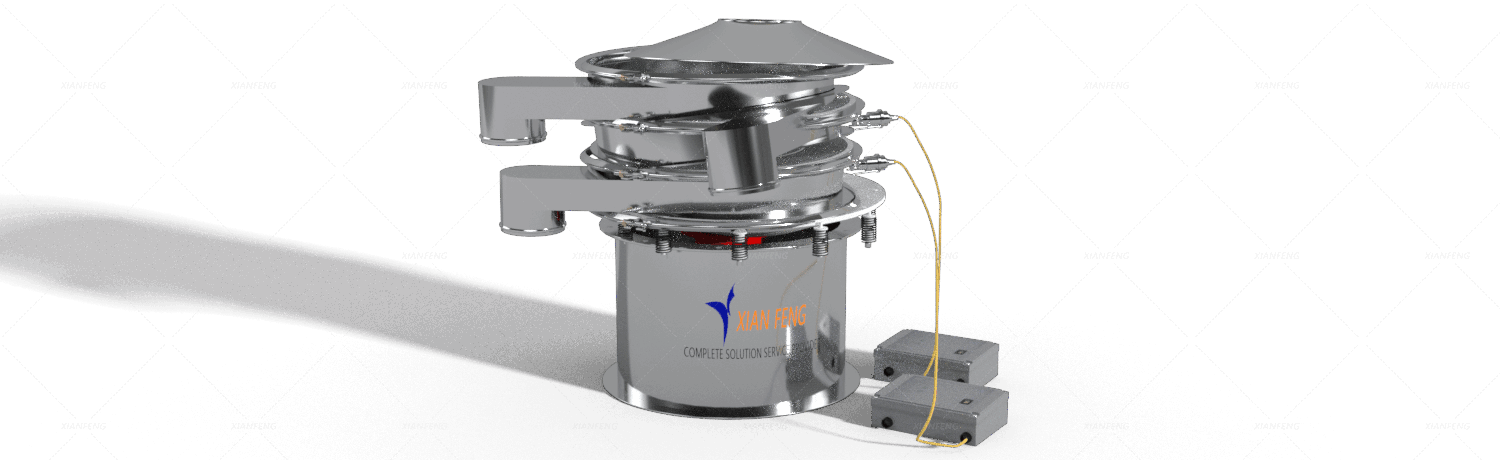

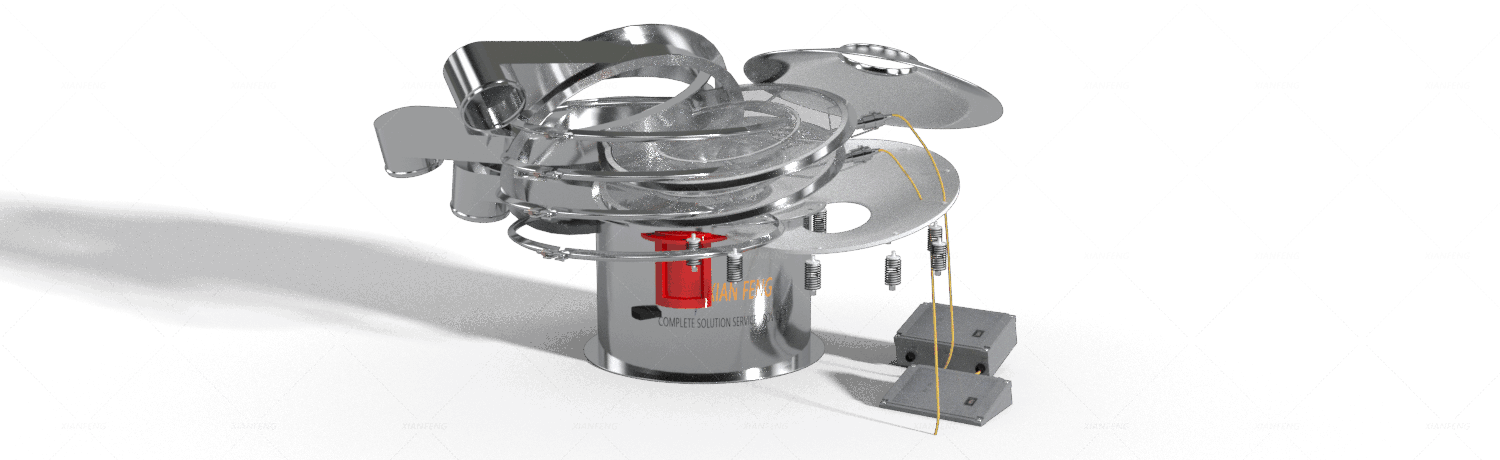

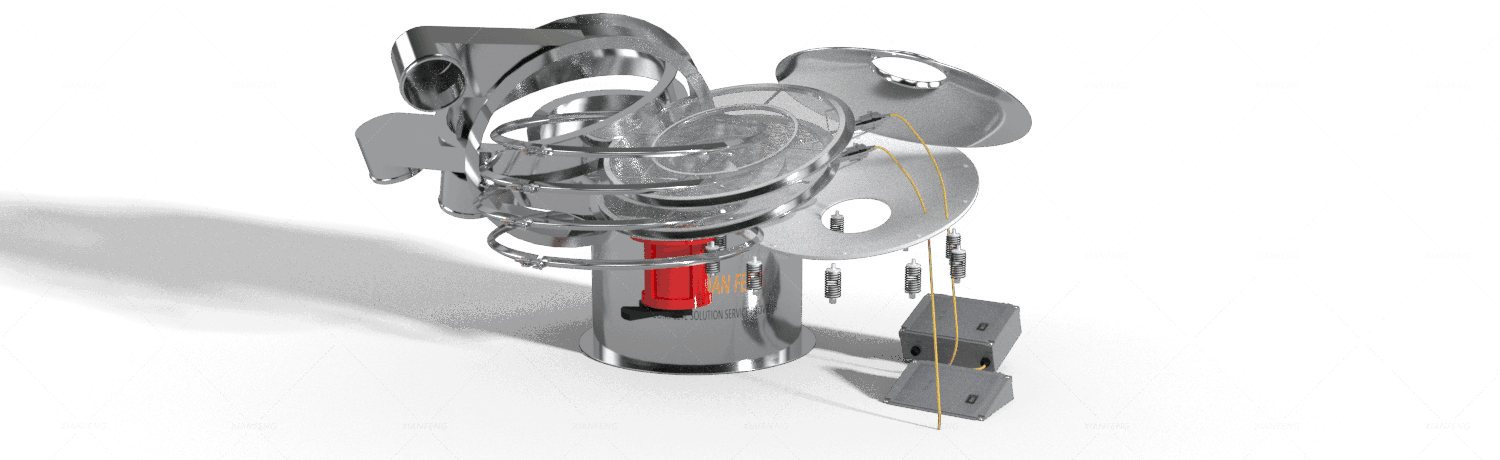

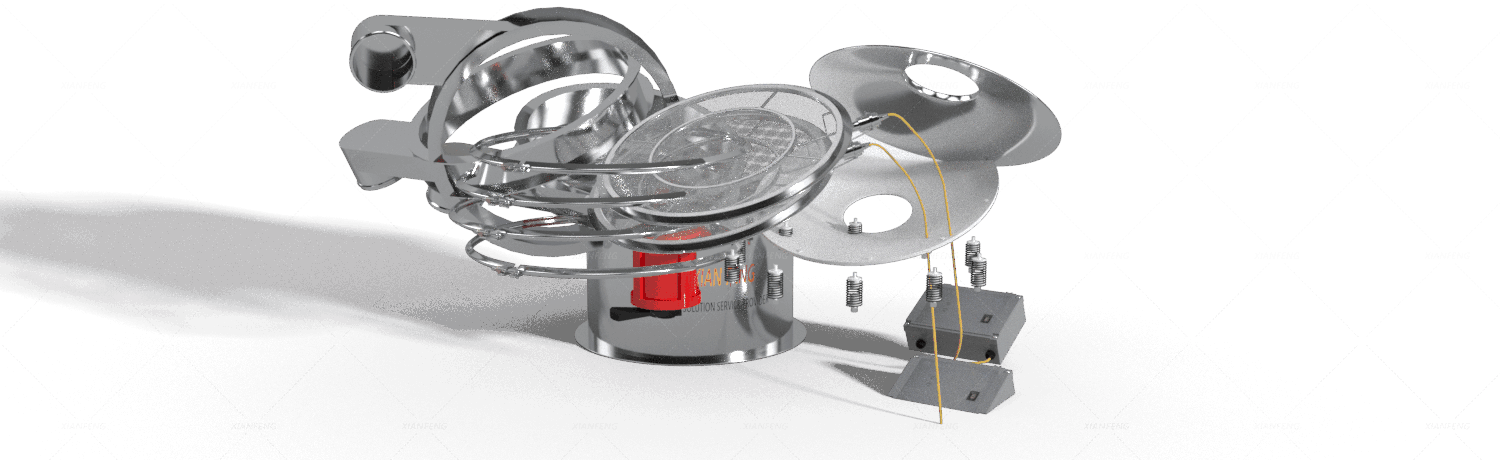

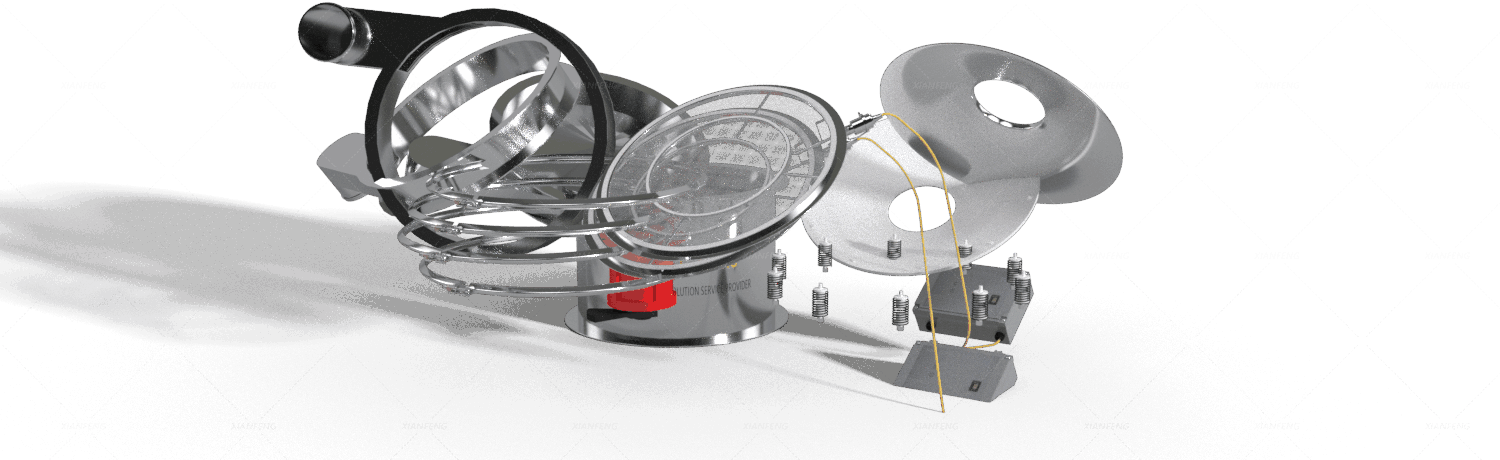

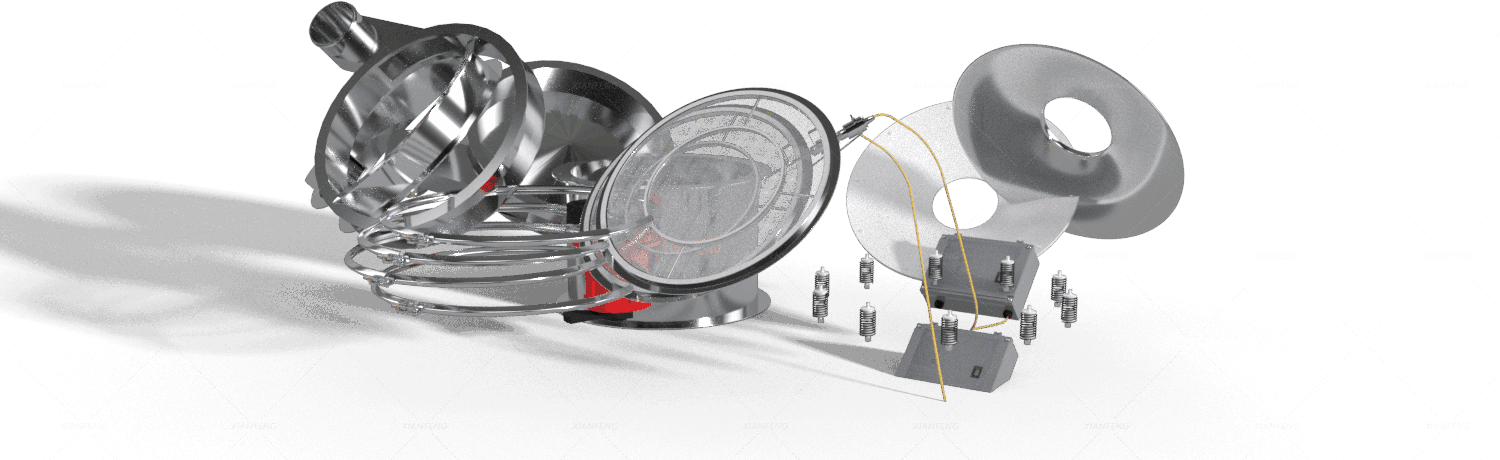

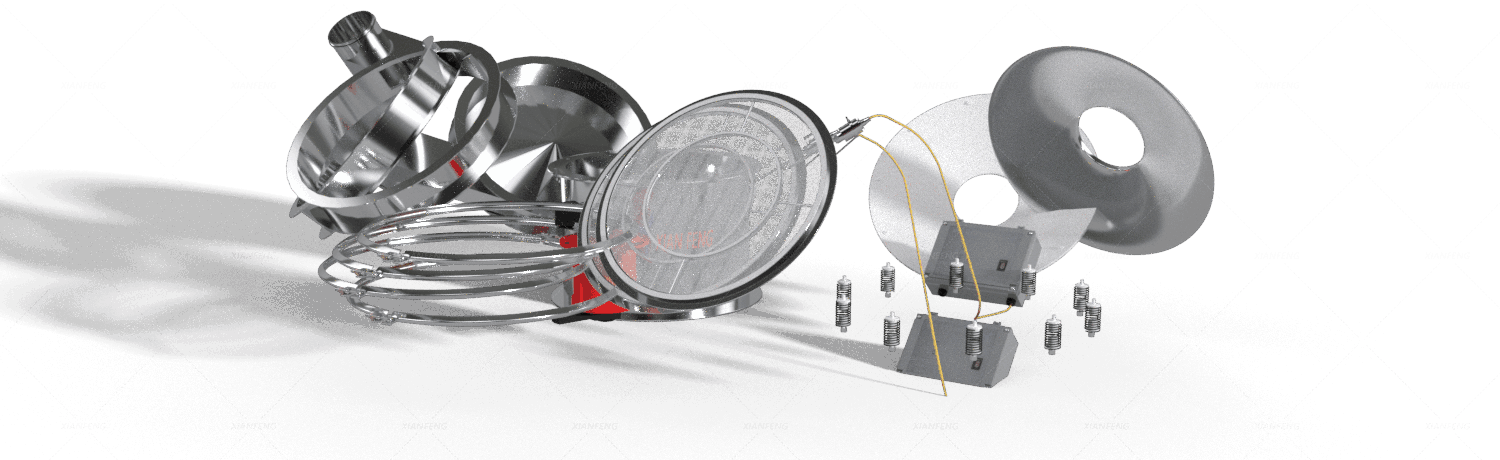

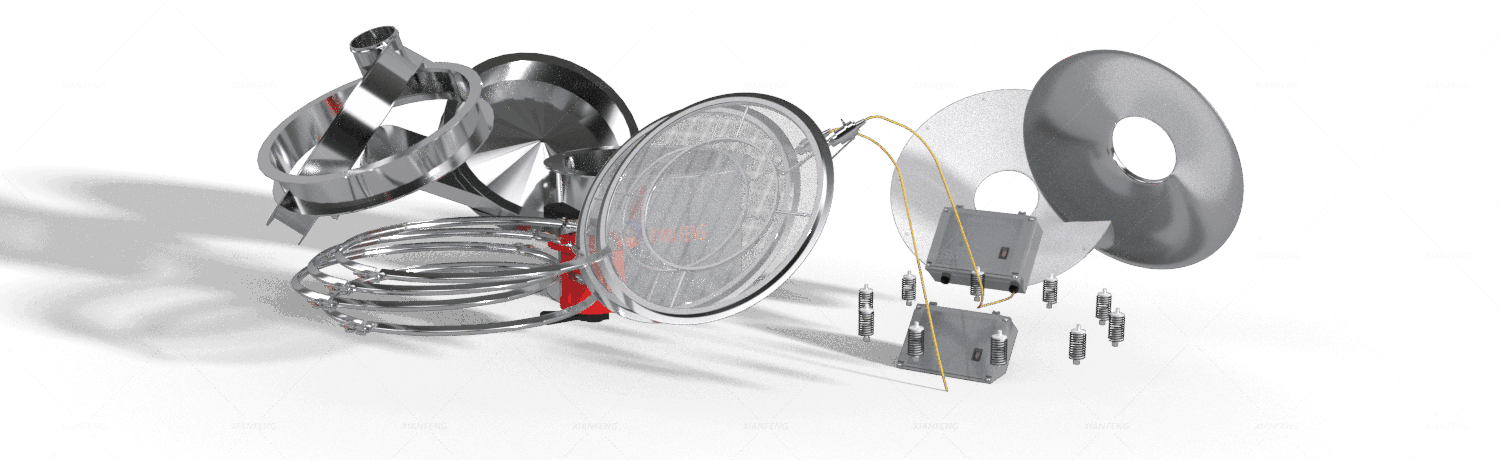

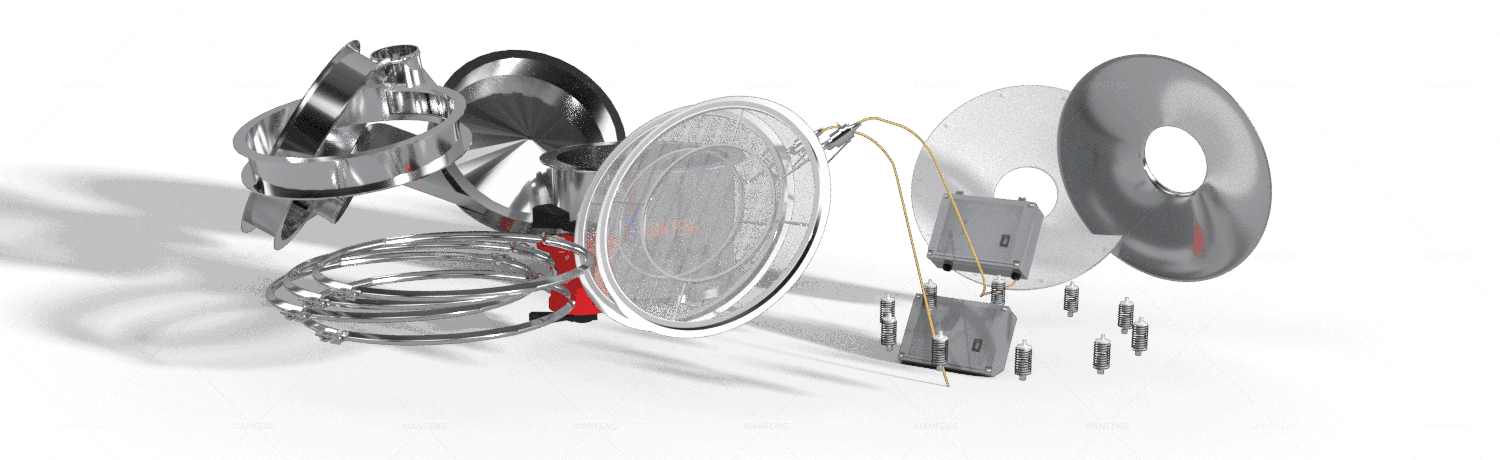

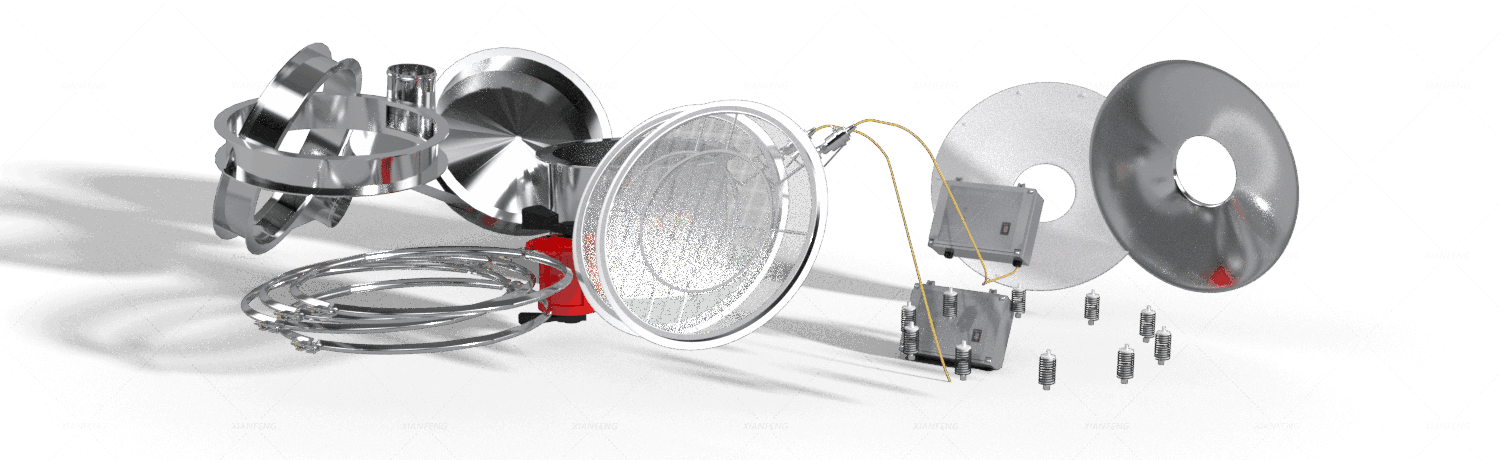

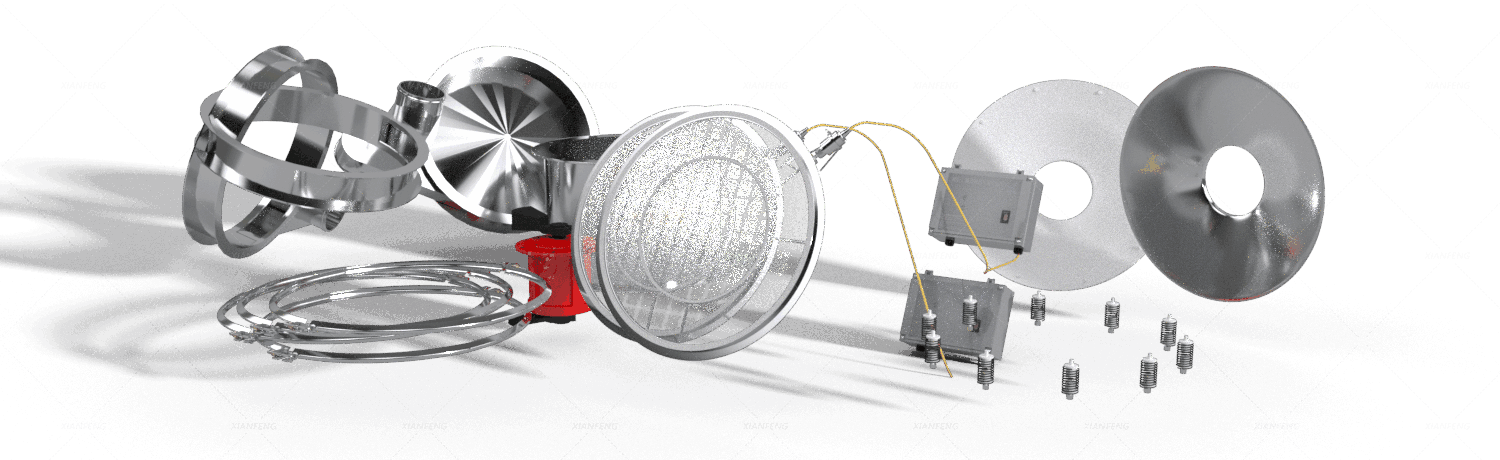

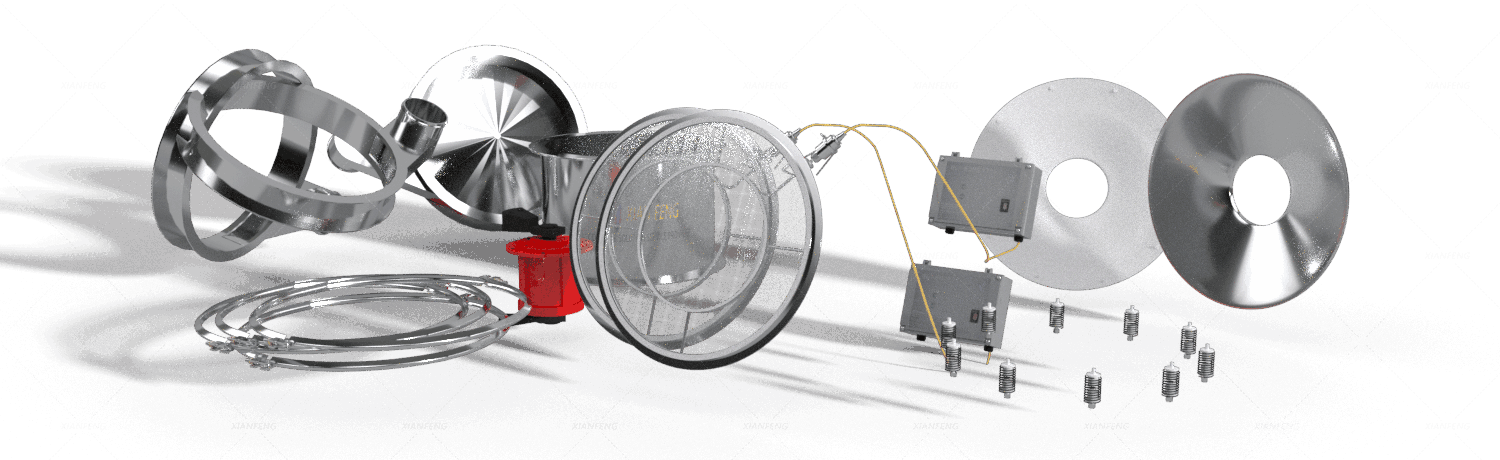

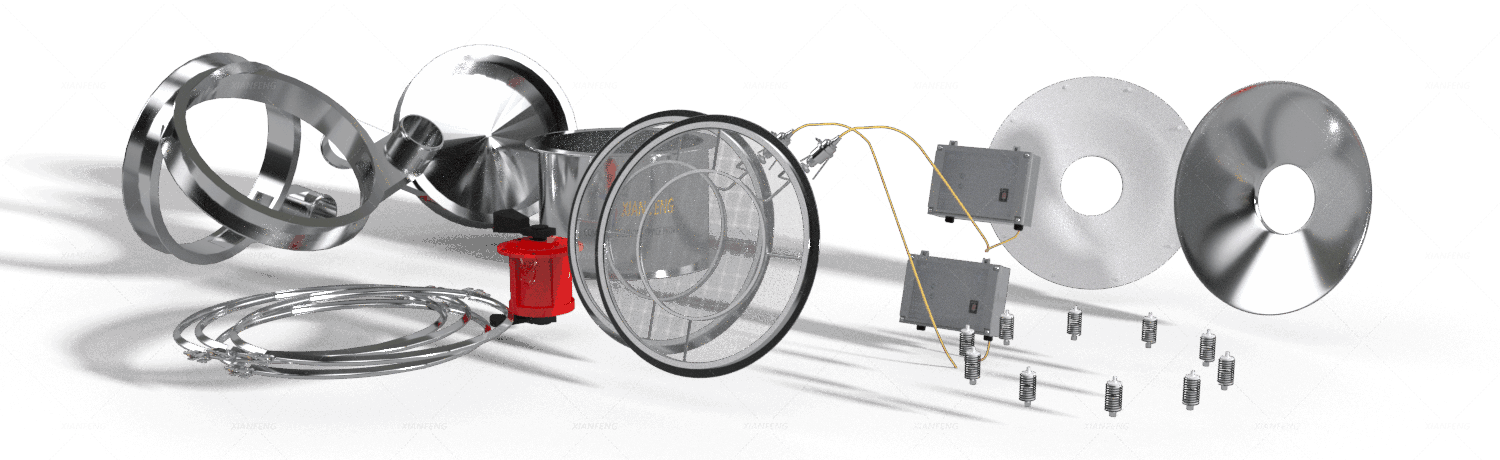

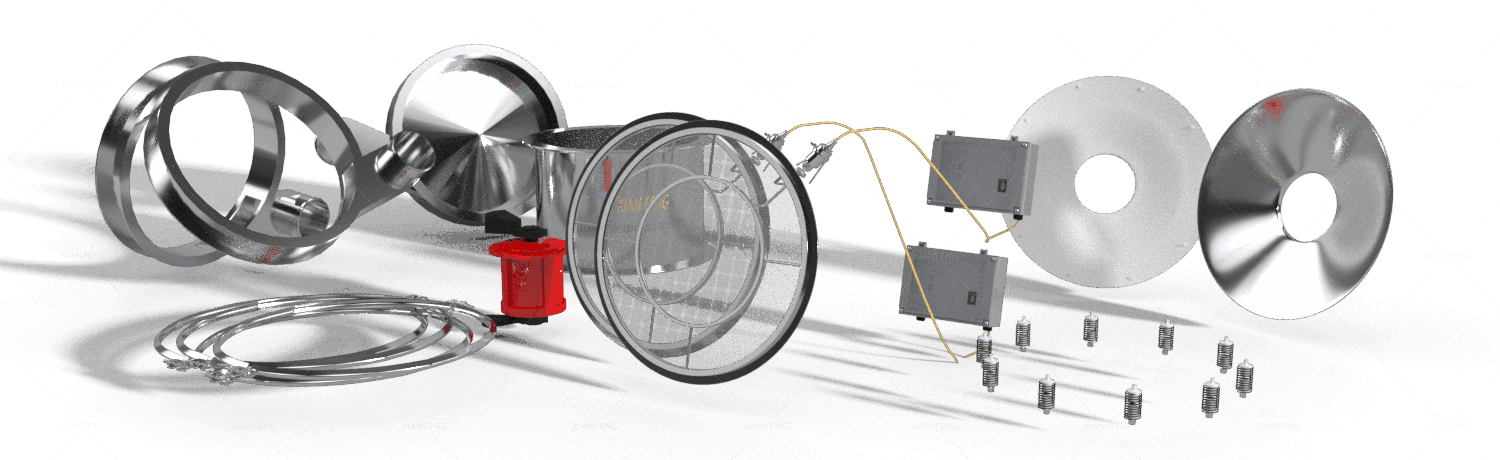

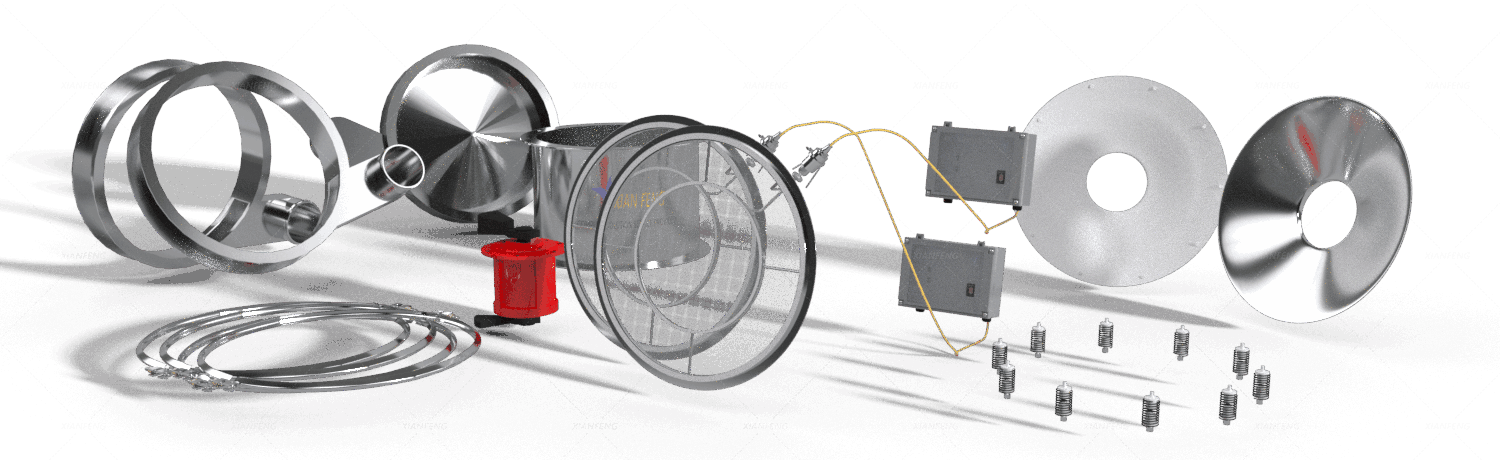

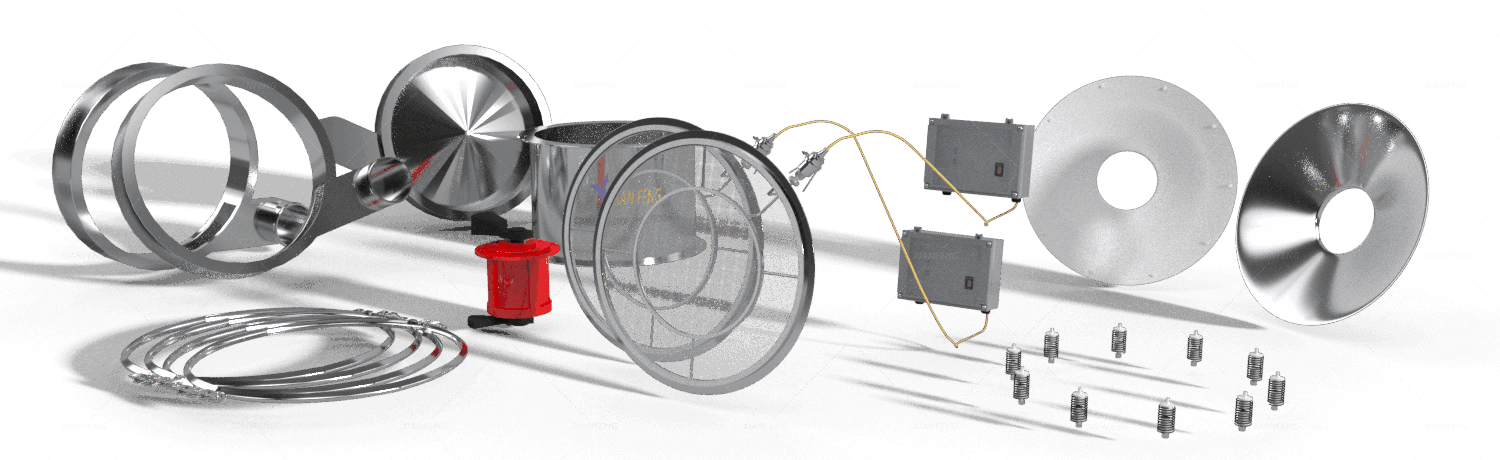

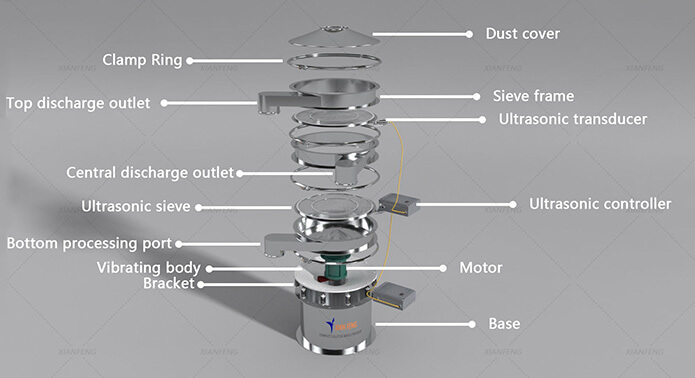

Ultrasonic structure

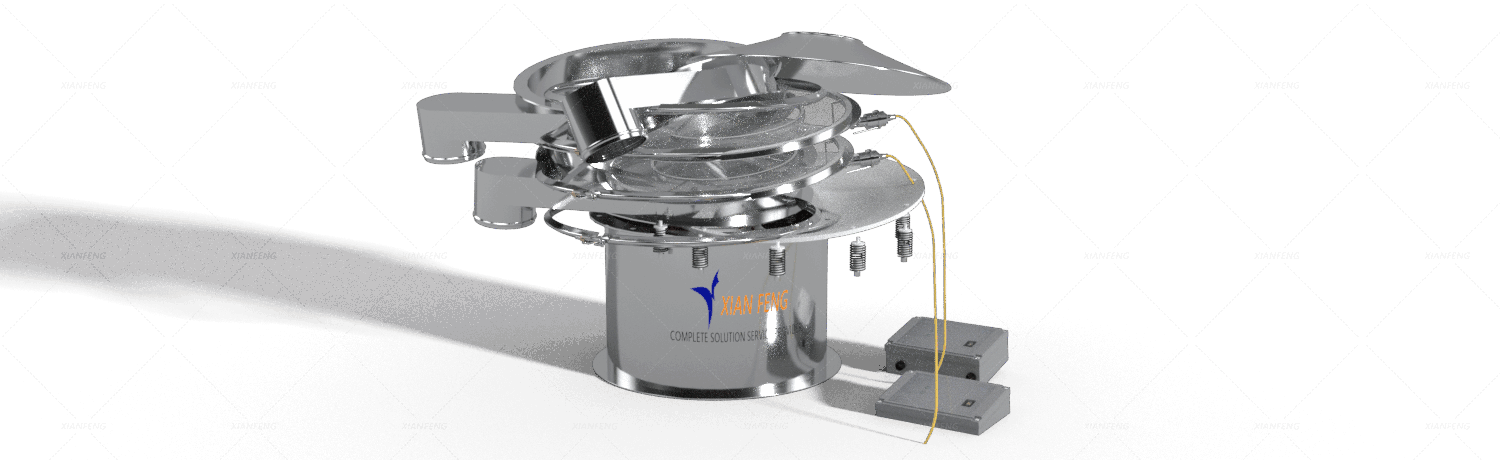

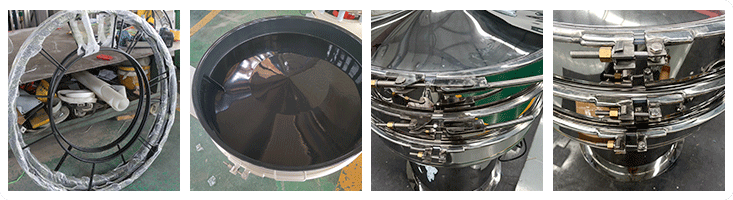

Discharge port and sieve frame

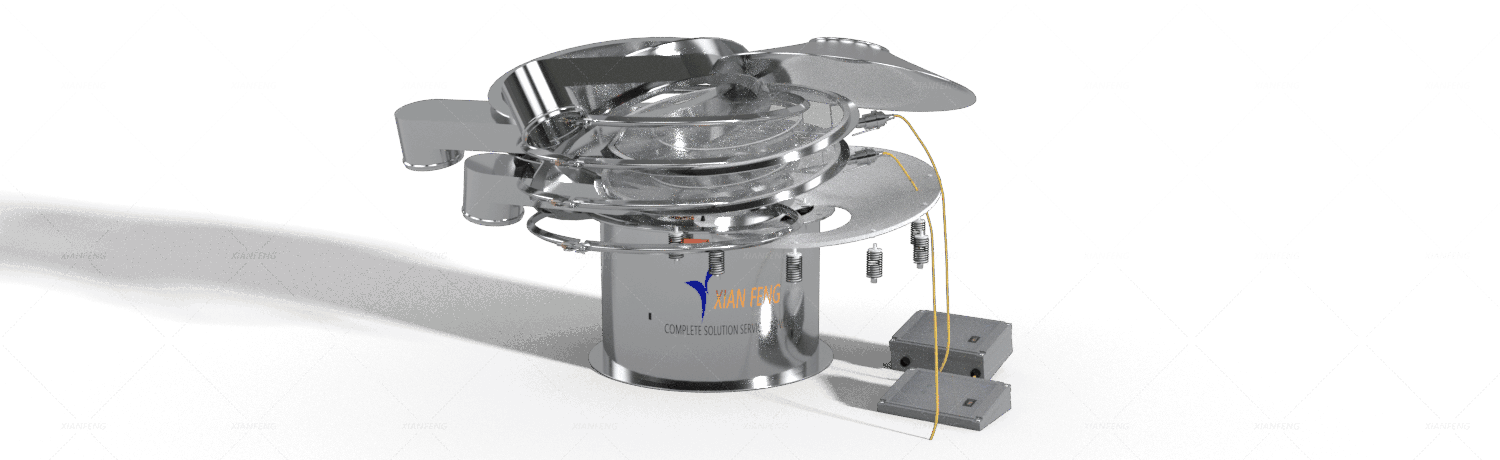

Surface treatment and related accessories

Ultrasonic controller

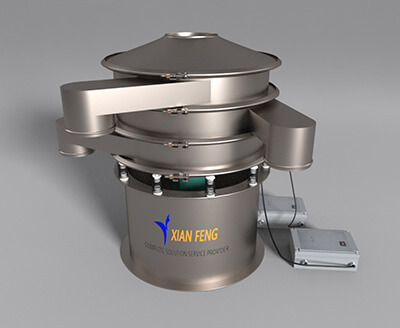

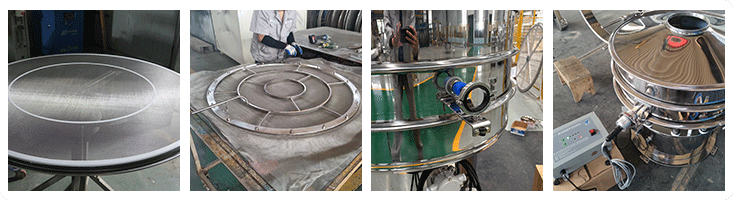

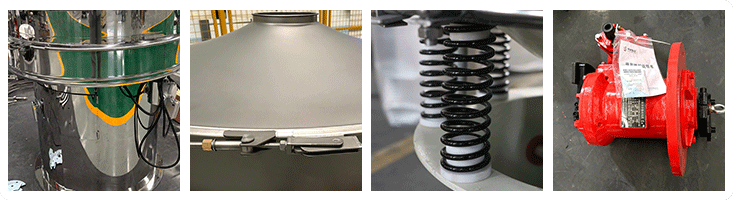

Ultrasonic vibrating screen undergoes fine polishing and grinding treatment

The feeding port can be customized according to needs and adapted to various connecting equipment

Strictly seal to eliminate the risk of material leakage

For special materials, Teflon coating spraying can be applied to the materials in contact to meet special screening requirements such as anti-static

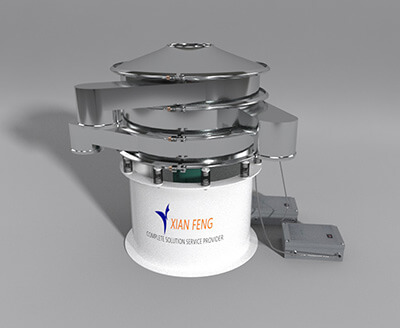

Customizable quick opening fastening structure for easier mesh replacement

Assemble 200-500 mesh screen according to customer requirements, with precise mesh holes.

Adopting thickened 304 stainless steel ultrasonic mesh, it completely solves the problem of traditional mesh cracking, has a longer service life, uniform amplitude transmission, and better cleaning effect on the mesh.

The XIAN FENG resonant ring amplification effect better distributes ultrasonic energy evenly across the entire screen surface, with no dead corners and higher efficiency and accuracy.

The discharge port is finely polished and strives for excellence to prevent contamination of customer finished materials, ensure product quality, and safeguard customer reputation.

Screen frame integrated roll round processing, rigid reinforced frame without deformation, good sealing, no material leakage, mirror polishing process, no cleaning dead corners.

XIAN FENG is the preferred choice for high-precision screening in high-value industries such as chemical, food, pharmaceutical, and new materials.

Multiple material and process options are available, and surface treatments such as wire drawing, polishing, sandblasting, etc. can be carried out according to customer requirements.

Using high-strength springs, the service life is longer and the anti resonance effect is better.

Adopting imported Ouli Wolong motors, it can produce continuously for a long time without any faults, with low energy consumption and high performance.

The ultrasonic controller stabilizes the output power and adjusts the frequency to control the amplitude as needed. Customers do not need to replace the equipment to achieve the cleaning effect of different specifications of materials on the screen, increasing the screening rate and improving production capacity.

Equipped with triple intelligent protection to prevent overload, overheating, and short circuit situations, providing customers with continuous production assurance.

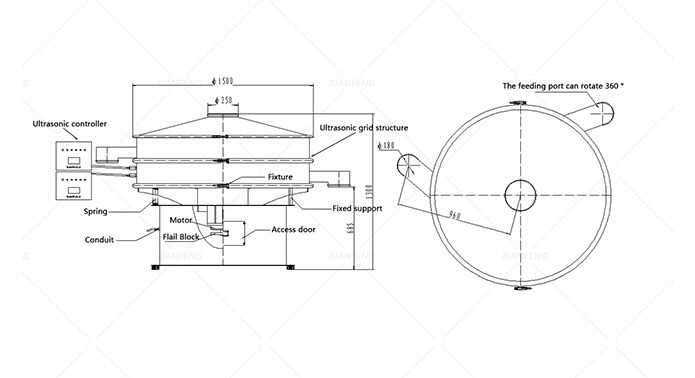

XIAN FENG ultrasonic vibrating screen is a high-precision screening equipment that adds ultrasonic system on the basis of ordinary vibrating screen. The core relies on the synergistic effect of mechanical vibration system (including vibration motor, exciter, screen frame) and ultrasonic system (including ultrasonic generator, transducer, amplitude rod) to achieve screening: after starting, the mechanical vibration system drives the exciter to generate centrifugal excitation force through the vibration motor, causing the screen frame to vibrate in a circular or linear manner, driving the material to move and layer on the screen surface, large particles to move towards the coarse material outlet, and fine particles to approach the screen hole; At the same time, the ultrasonic generator converts power frequency electricity into high-frequency electrical signals, which are then converted into high-frequency mechanical vibrations by a transducer. After amplification by an amplitude rod, the vibrations are transmitted to the screen mesh, causing it to produce high-frequency micro amplitude vibrations. This not only destroys the adsorption or adhesion of fine powder and viscous materials to the screen mesh, avoiding clogging, but also loosens the fine powder layer, reduces agglomeration, and accelerates screen penetration; In the end, fine powder that meets the particle size is discharged from the fine material outlet through the sieve holes, and large particles are discharged from the coarse material outlet. The efficiency is improved by 30% -100% compared to ordinary vibrating screens, which can efficiently solve the problem of fine powder screening. It is widely used in high-precision fine powder screening scenarios in industries such as medicine, food, and chemical engineering.

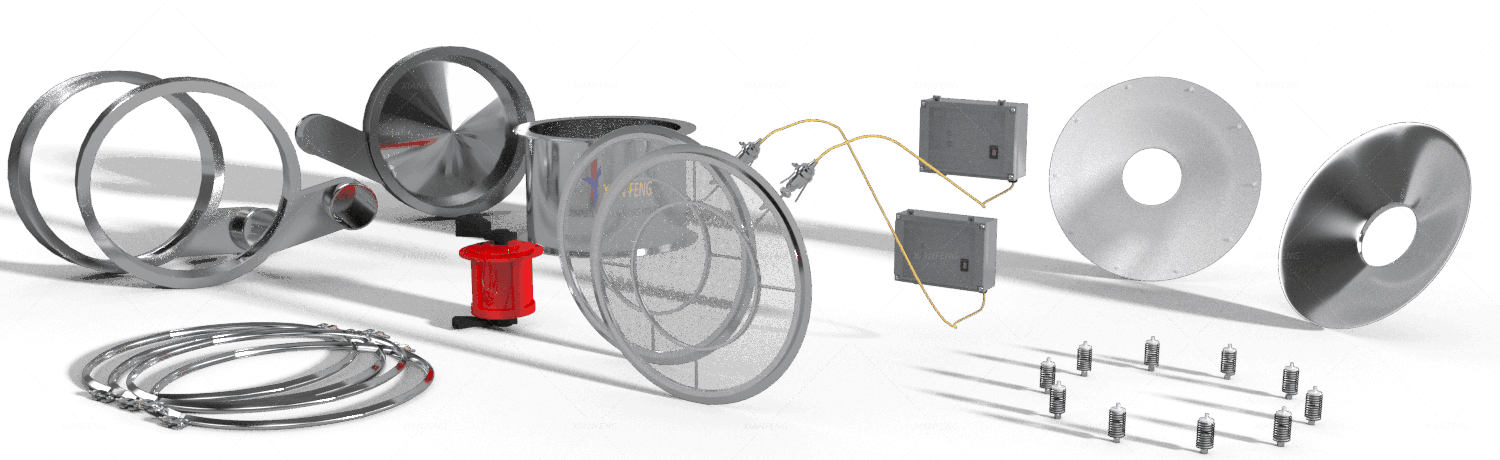

dust cover, screen frame, screen mesh, cleaning elastic ball, punching tray, tie ring, spring, vertical motor, and base.

Its main function is to prevent internal materials or dust from overflowing during feeding. It can be customized according to the actual situation to adapt to different feeding equipment.

Shaped by a high-precision coiling machine and welded with fish scale patterns to ensure strength, it ensures no looseness, deformation, or cracking under high-frequency vibration, and efficient transmission vibration ensures screening efficiency.

Made of 304/316 stainless steel, the ultrasonic screen is the "screening execution end" that receives ultrasonic energy. The core difference from ordinary screens is the built-in ultrasonic transducer/energy conduction layer, which ensures that high-frequency vibration evenly covers the screen surface and is the key to achieving "anti blocking+high precision". Commonly used for screening materials with a mesh size of 200 or more.

The ultrasonic grid is a bridge between the "ultrasonic system" and the "screen mesh". Its core function is to evenly transmit ultrasonic energy and stably support the screen mesh, avoiding "local blockage" caused by uneven energy distribution, while ensuring easy installation of the screen mesh.

Made of rubber/silicone material to meet various material requirements, ensuring elasticity, durability, and preventing damage, powder loss, and material contamination.

made of high-strength steel material, with rounded and polished material that does not adhere during cutting.

V-shaped is used for connecting and interlocking components such as screen frames, with high quality and no vibration cracking. Bolts or quick opening structures are optional.

High load-bearing, high elasticity spring, efficient shock absorption and wear resistance.

Imported Ouli Wolong motor is used, with high amplitude and low power, which is more energy-efficient. Explosion proof motor can be selected to meet special needs.

The unique high-strength steel cone design evenly distributes the vibration force to the screen frame and screen surface, reducing energy loss and improving screening efficiency.

Rigid support to resist resonance, built-in optimized shock absorption structure to reduce ground impact and ensure equipment safety.

Fine powder screening

Silicon carbide powder screening

Ultrasonic screening of lithium battery materials

Ultrasonic screening of graphite powder

| Model | Screen Dia. (mm) |

Screening area (m²) |

Meshsize (mesh) |

Screen layers | Motor power (kw) |

|

| XFC-600 | φ560 | 0.25 | 2-500 | 1-3 | 0.25 | |

| XFC-800 | φ760 | 0.45 | 2-500 | 1-3 | 0.55 | |

| XFC-1000 | φ950 | 0.71 | 2-500 | 1-3 | 0.75 | |

| XFC-1200 | φ1150 | 1.05 | 2-500 | 1-3 | 1.1 | |

| XFC-1500 | φ1450 | 1.6 | 2-500 | 1-3 | 1.5-3 | |

Ordinary vibrating screen (rotary vibrating screen): It usually processes materials with a mesh size of 2-200, and materials with a mesh size exceeding 200 may cause clogging.

Ultrasonic vibrating screen: Processing materials in the range of 200-500 mesh on the basis of ordinary vibrating screens, it has a good cleaning effect on fine powder screening and prevents mesh blockage.

Rotary vibrating screen is a widely used vibrating screen. Ultrasonic vibrating screen is a specialized equipment designed for screening difficult problems such as easy blockage of fine powder screening and classic adsorption of fine powder.

Its core advantage is to handle fine powders/micro powders that are prone to clogging and difficult to screen, with typical applicable materials including:

Fine powders: flour, milk powder, protein powder, traditional Chinese medicine powder, graphite powder, carbon black, talc powder, calcium carbonate powder;

Easy to absorb moisture/clump: laundry detergent powder, monosodium glutamate powder, pesticide raw material powder, feed additives;

Light weight/easy to float category: lightweight calcium carbonate, mica powder, kaolin, titanium dioxide, plastic masterbatch powder;

High precision requirements: electronic powders (such as soldering tin powder, ceramic powder), pharmaceutical intermediates, food additives (such as aspartame).

Attention: It is not suitable for screening "high viscosity paste like materials" (such as dough, paste) or "large particle block like materials" (such as mineral blocks).

Okay. As long as materials and designs that meet food/pharmaceutical grade standards are selected, industry requirements can be met:

Material requirements: The parts in contact with the material (screen frame, sieve mesh, sealing ring) should be made of 304/316L stainless steel to avoid material contamination;

Sanitary design: The inner and outer surfaces of the equipment should be smooth and free of dead corners (easy to clean), and some models support a "quick release structure" (convenient for disassembly, cleaning, and sterilization);

Compliance: By selecting FDA certified components from the food industry and GMP certified components from the pharmaceutical industry, ultrasonic vibrating screens can meet food hygiene or drug production standards.

The core reasons for poor accuracy are usually related to "screen mesh, ultrasonic parameters, feeding method", corresponding solutions:

Mesh issue:

Reason: Insufficient tension of the screen mesh (sagging of the screen mesh during vibration and easy leakage of particles), damaged screen mesh (with holes);

Solution: Re tighten the screen (adjust the screen pressing ring) and replace the screen with a new one.

Ultrasonic parameter mismatch:

Reason: Ultrasonic frequency is too high/too low (such as when the material has a light density and the frequency is too high, causing particles to be excessively suspended and unable to pass through the sieve);

Solution: Fine tune through the "frequency adjustment" of the ultrasonic generator (usually 20-30 kHz, determine the optimal value after screening).

Uneven feeding:

Reason: The feeding port is biased towards one side of the screen surface, resulting in local material being too thick;

Solution: Adjust the feeding port position or install a "distributor" to evenly distribute the material on the screen surface.

Changes in material characteristics:

Reason: The material particle size fluctuates greatly and contains too many impurities;

Solution: First, preprocess the materials (such as removing impurities and grading), and then proceed to the screening process.

Support customization, common customization directions include:

Material customization:

Corrosive materials (such as hydrochloride powder): 316L stainless steel is used for the contact part;

Food/pharmaceutical industry: Use food grade stainless steel with mirror polishing treatment (easy to clean).

Structural customization:

Multi layer screening (such as "2-layer screen, divided into 3 levels");

Sealed design (such as "fully sealed structure to prevent dust leakage", used for toxic/dust prone materials);

Special Features:

Explosion proof design (for flammable and explosive materials such as flour, coal powder, sulfur powder, equipped with explosion-proof motor and explosion-proof ultrasonic system);

Automated docking (such as linkage with front-end feeders and back-end packaging machines to achieve unmanned production), etc.

23 years of experience specializing in screening and conveying equipment manufacturing [Rich experience, providing complete customized solutions]

40,000 square meter factory, a genuine source manufacturer [No middlemen, lower prices]

50 technical patents, CE/ISO certifications [Technology proven, trustworthy]

20 years of export experience, equipment exported to over 70 countries worldwide [Full-process support from a professional team]

Ensure your product quality and reputation.

Our professional solutions are designed to maximize your production efficiency.

Reduce production downtime, resource waste, and maintenance issues.