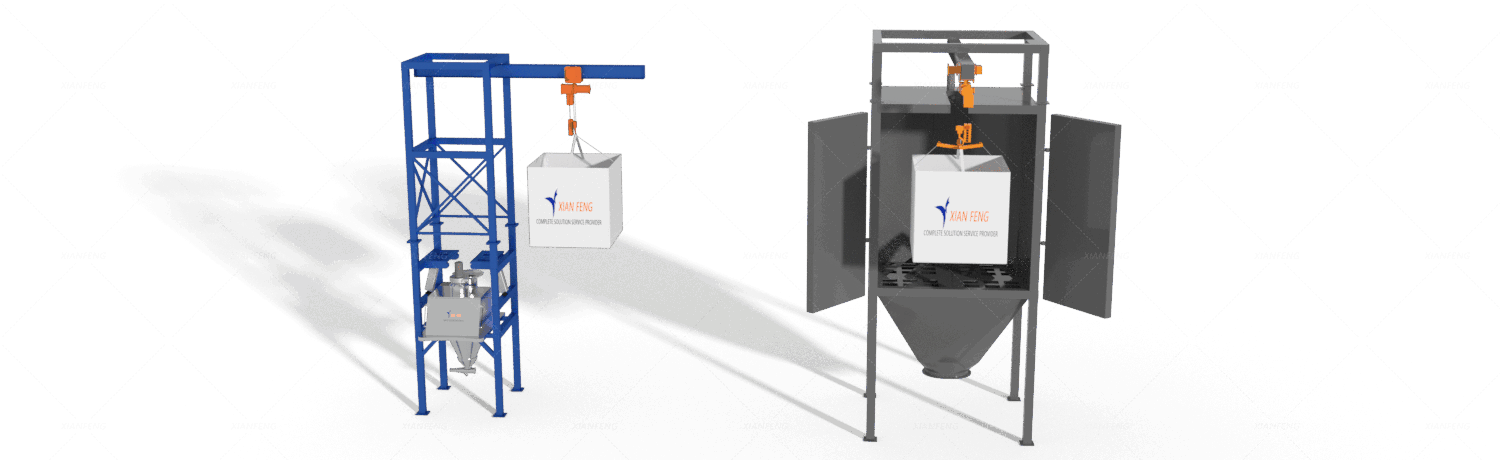

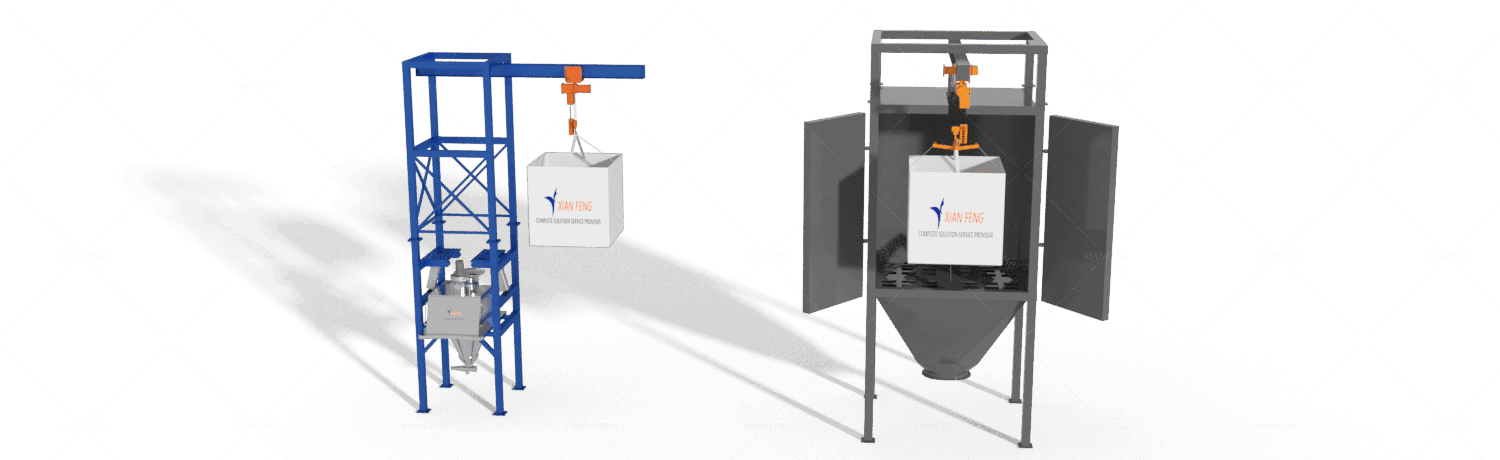

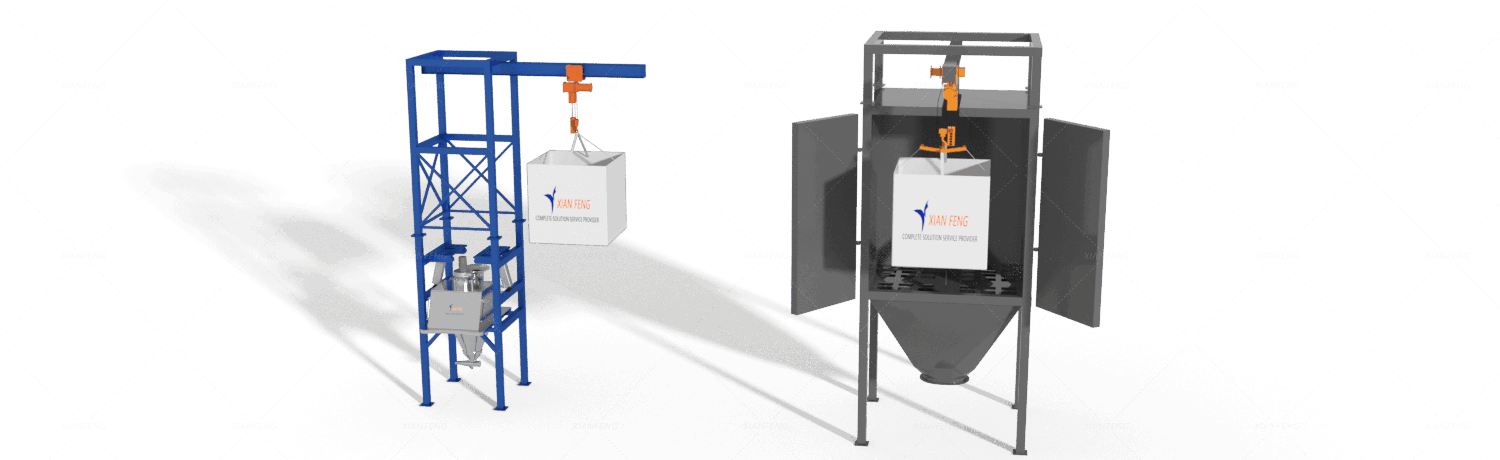

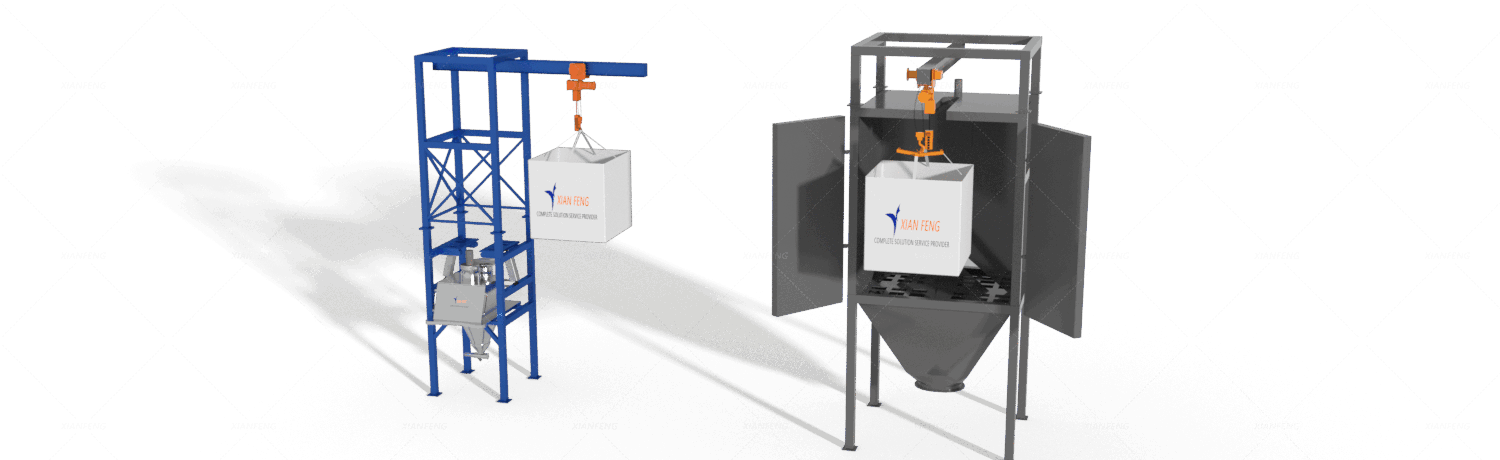

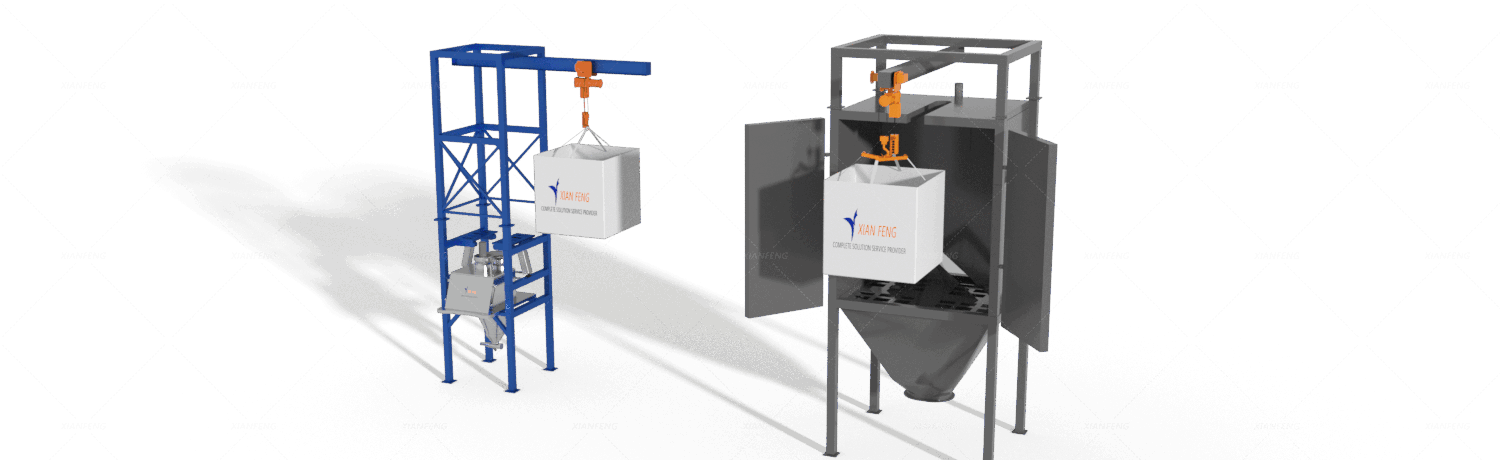

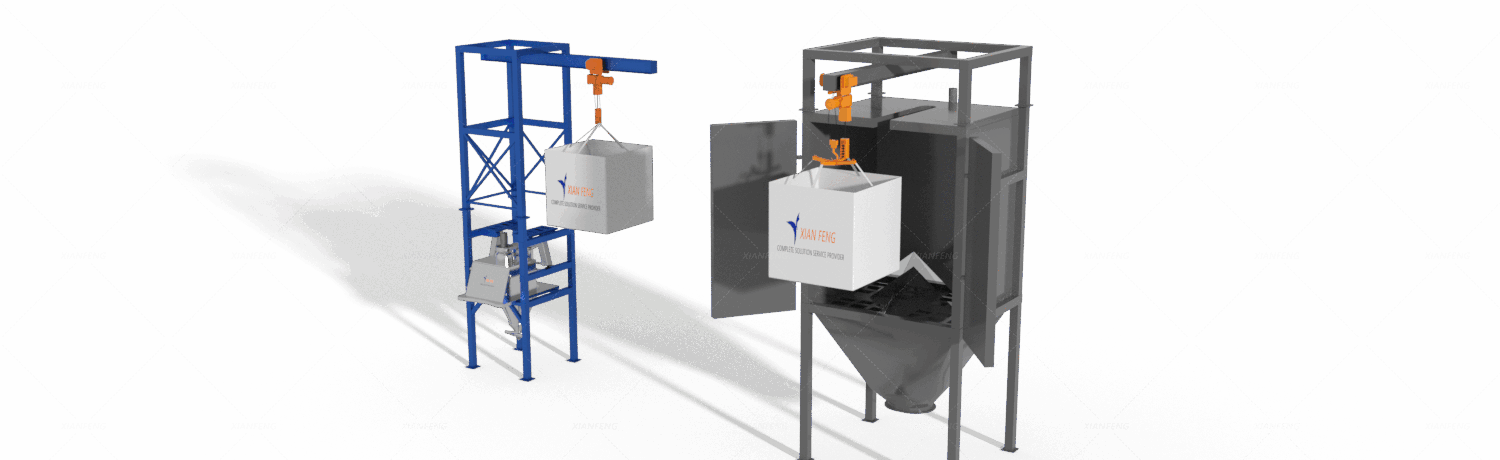

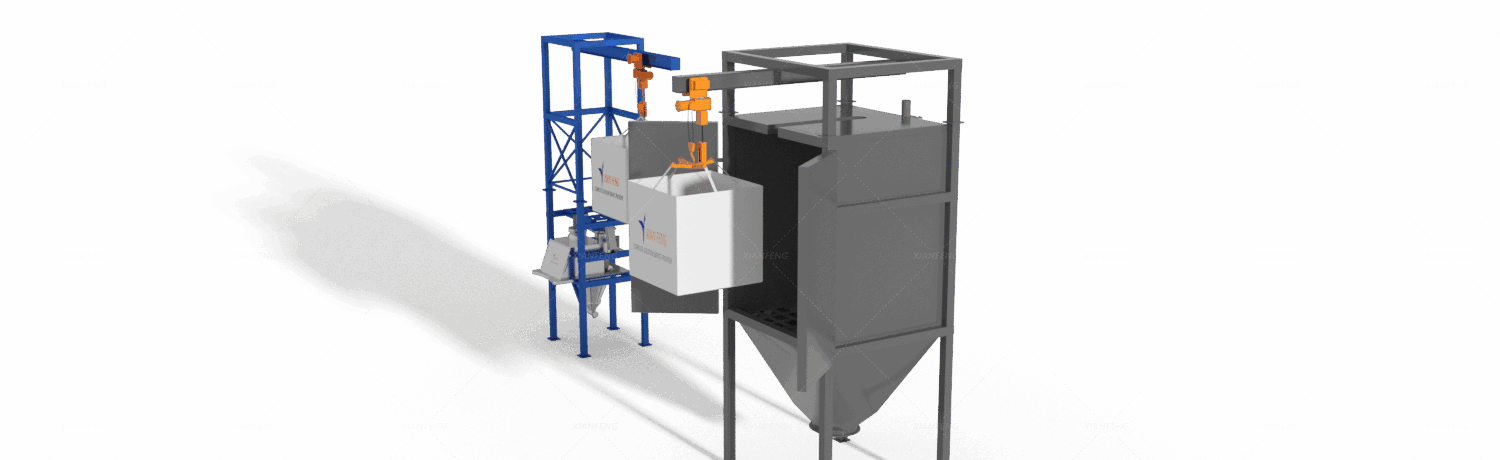

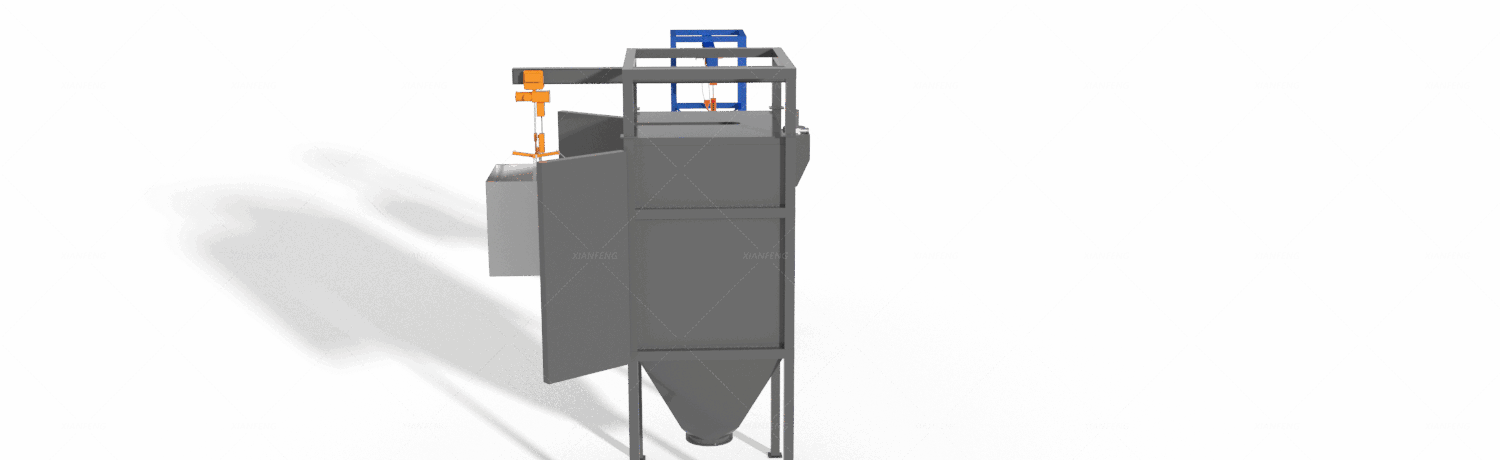

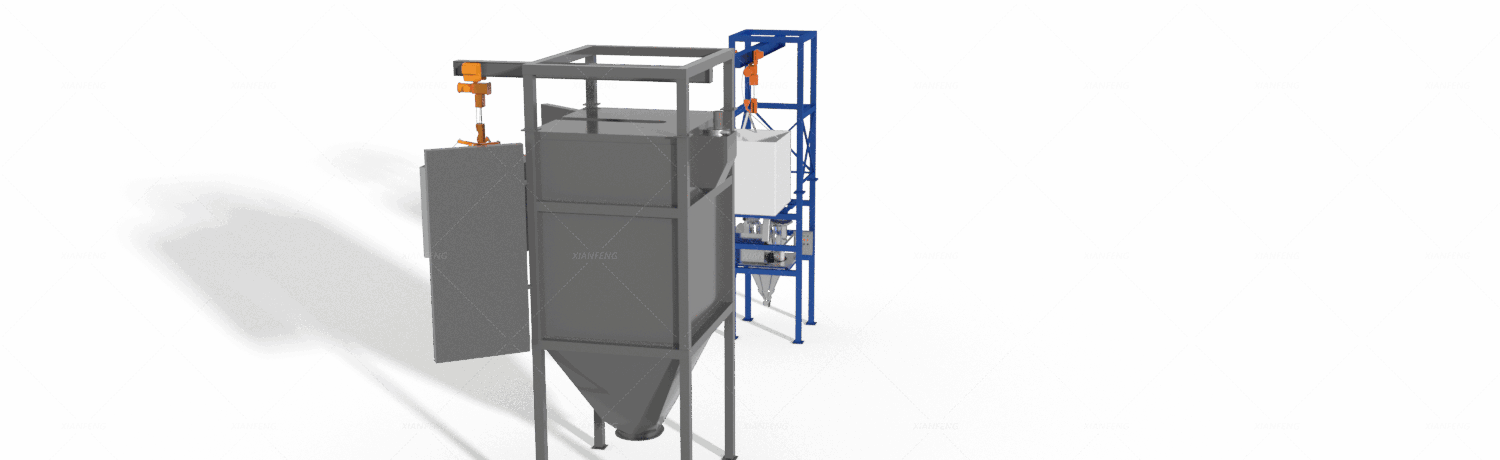

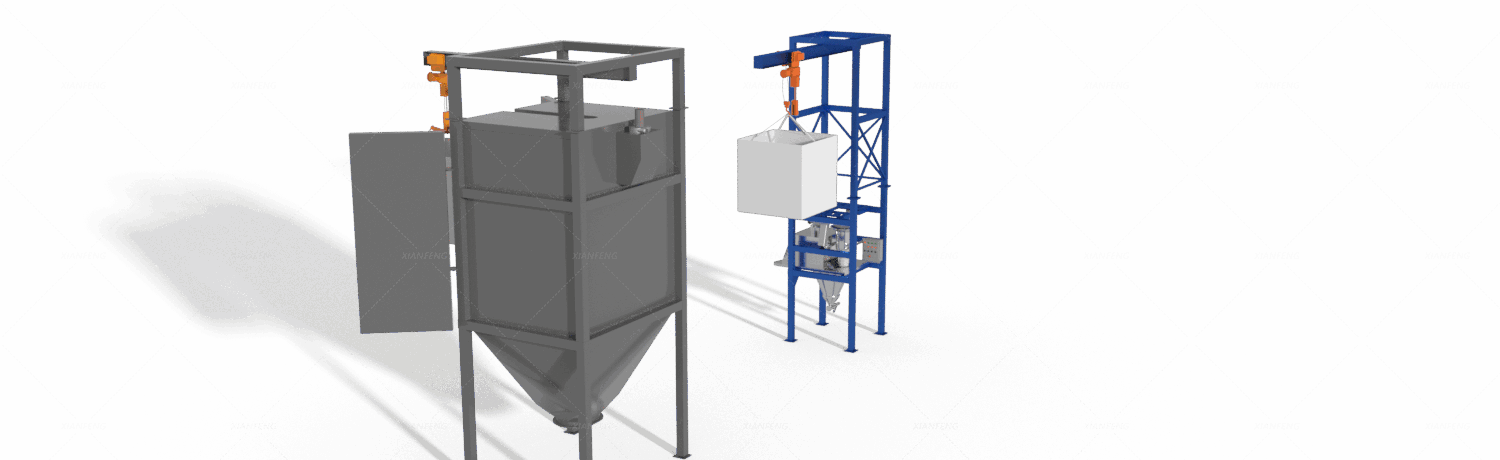

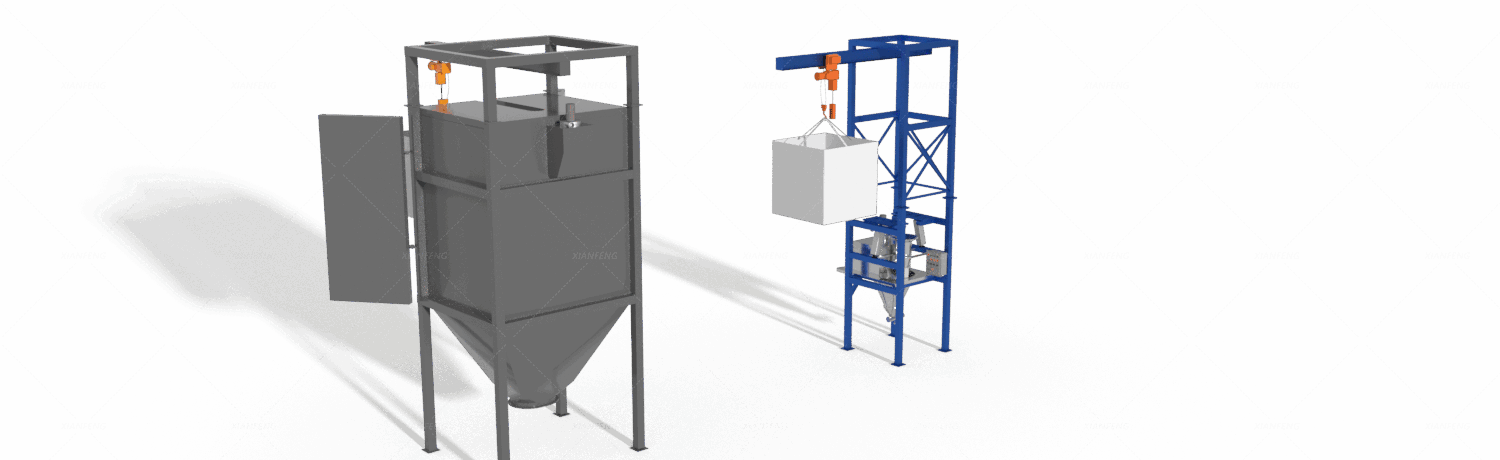

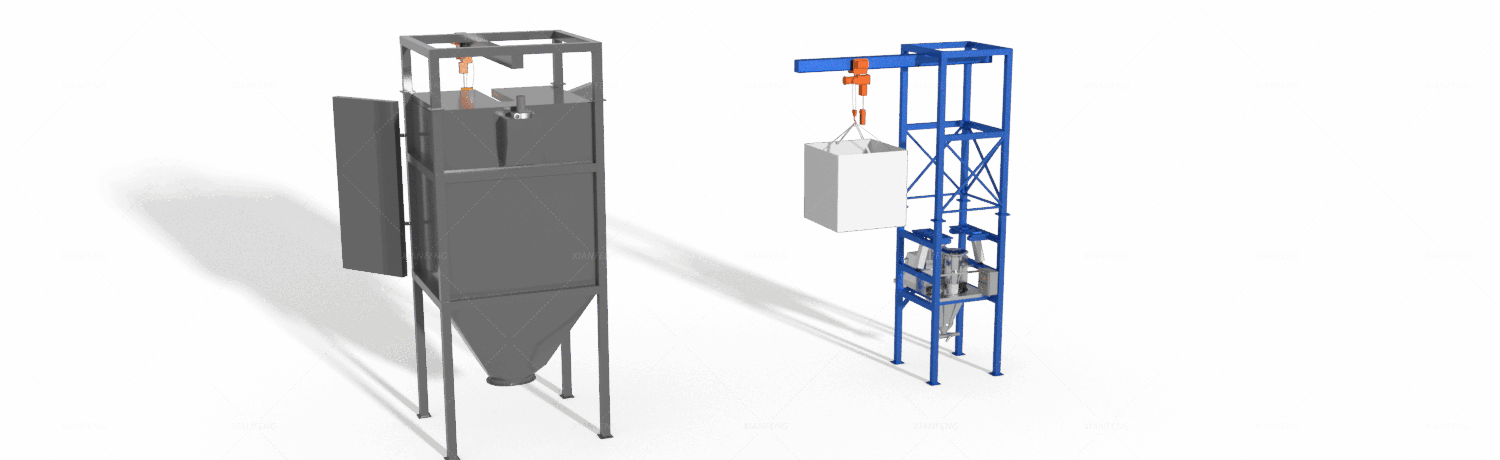

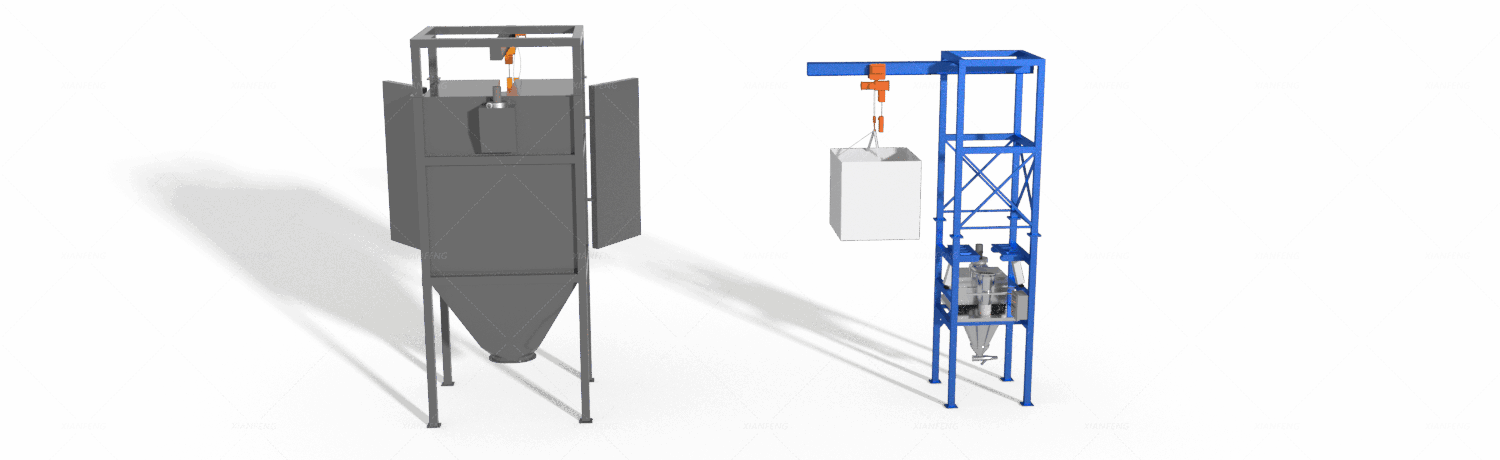

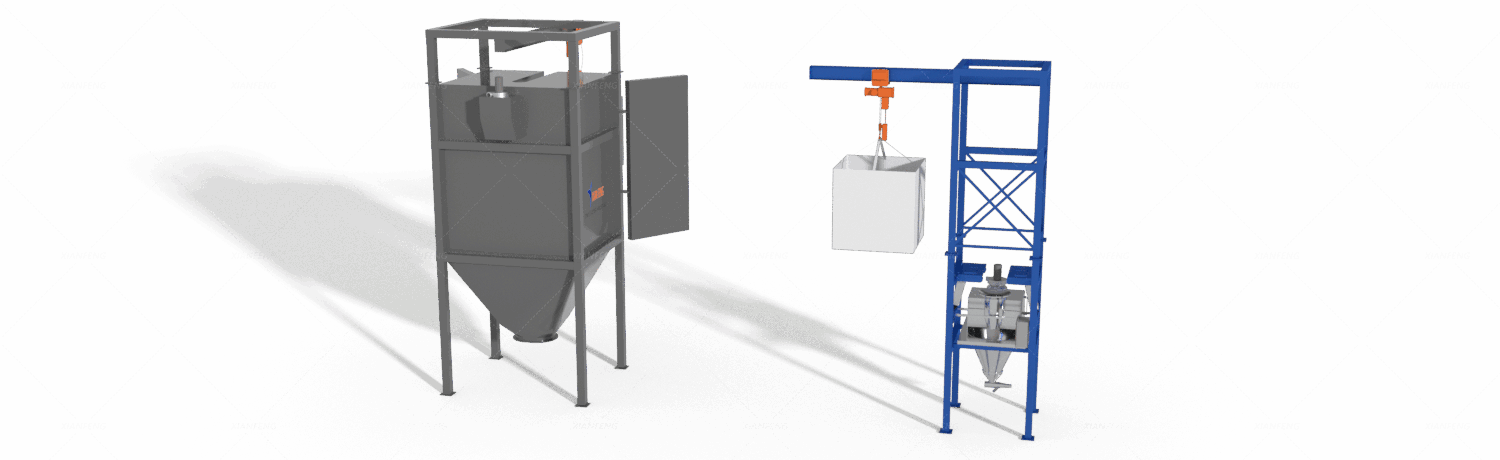

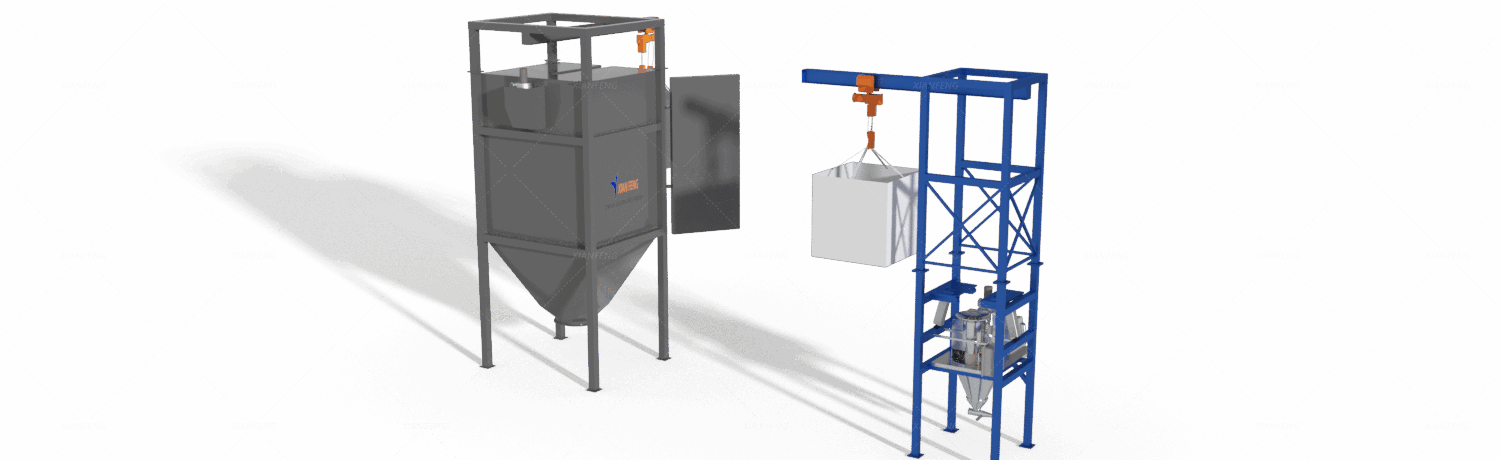

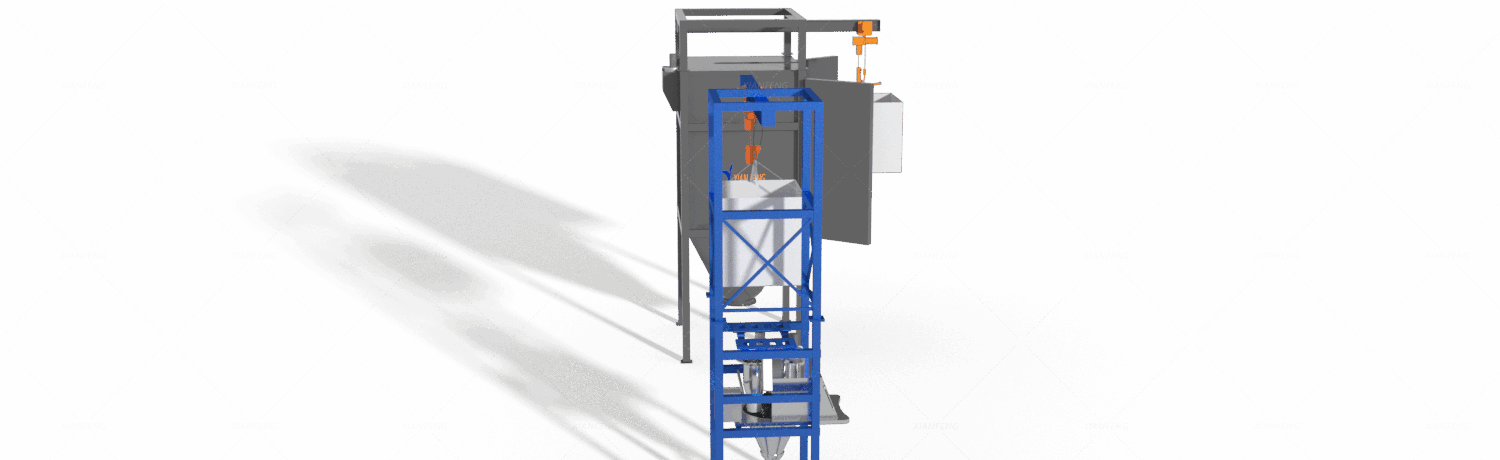

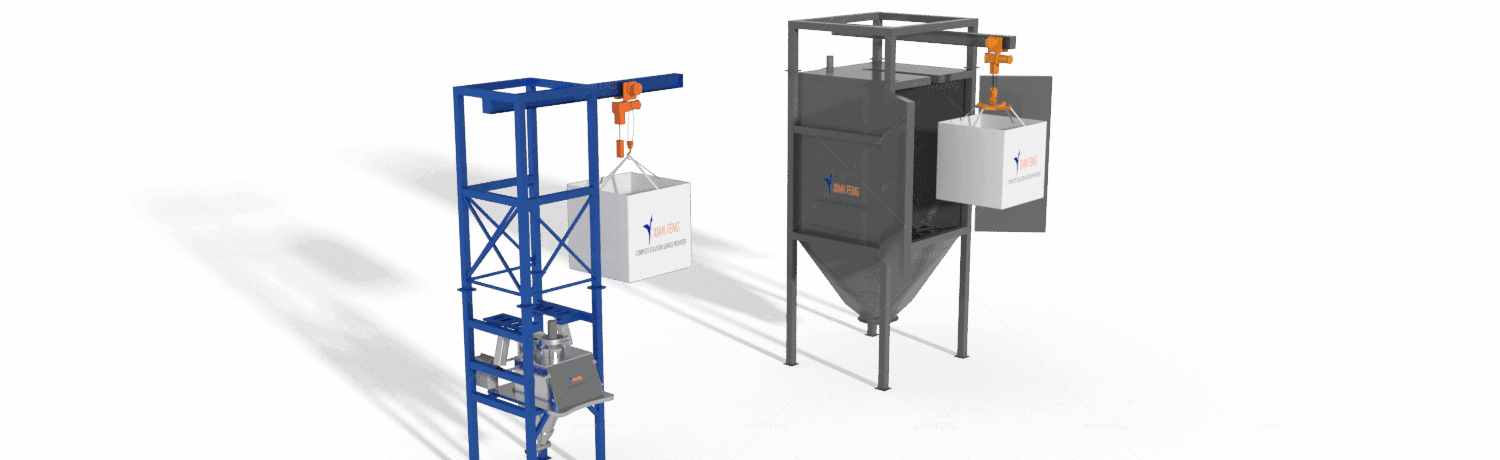

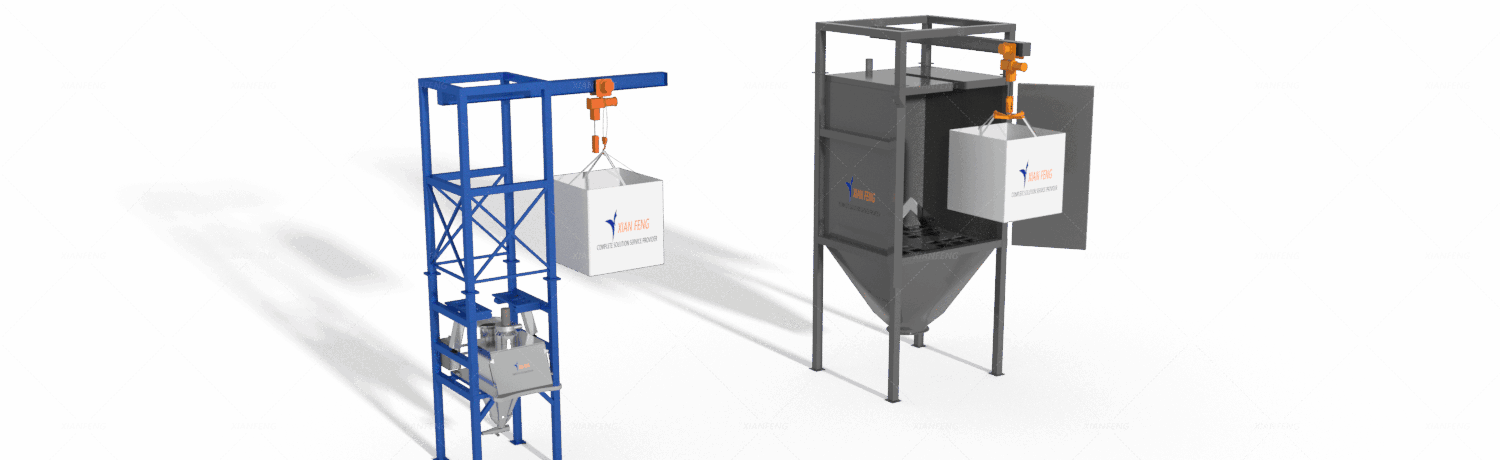

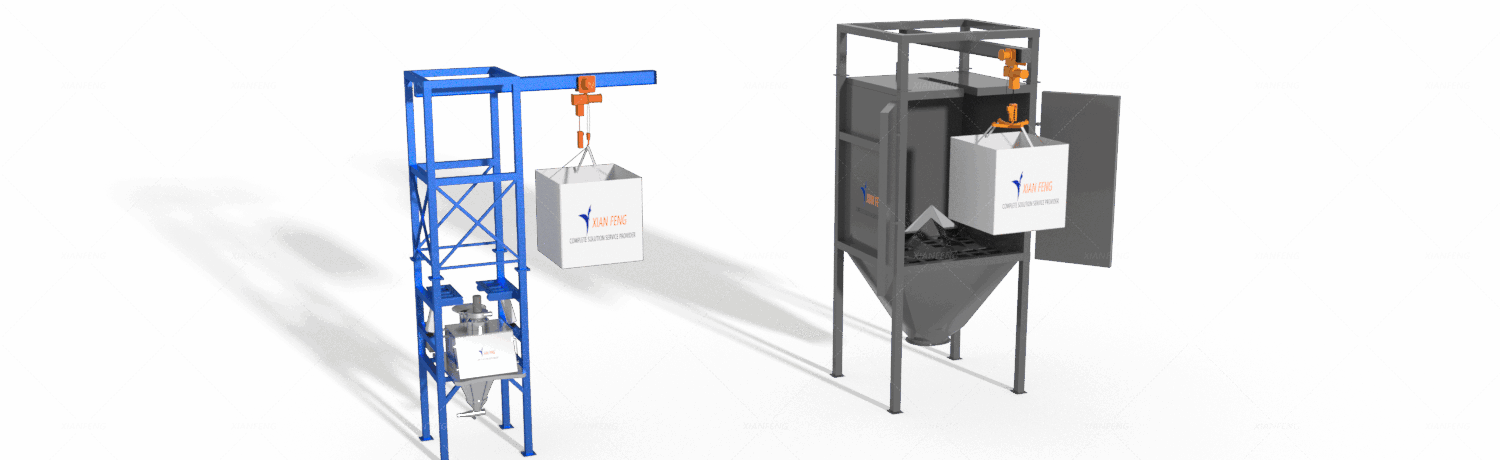

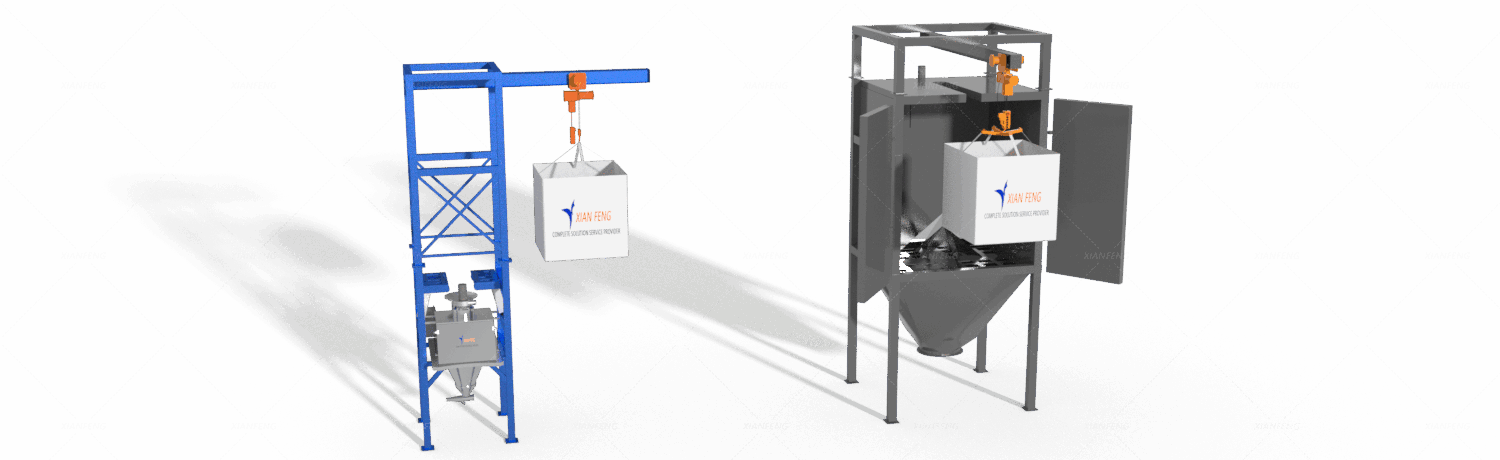

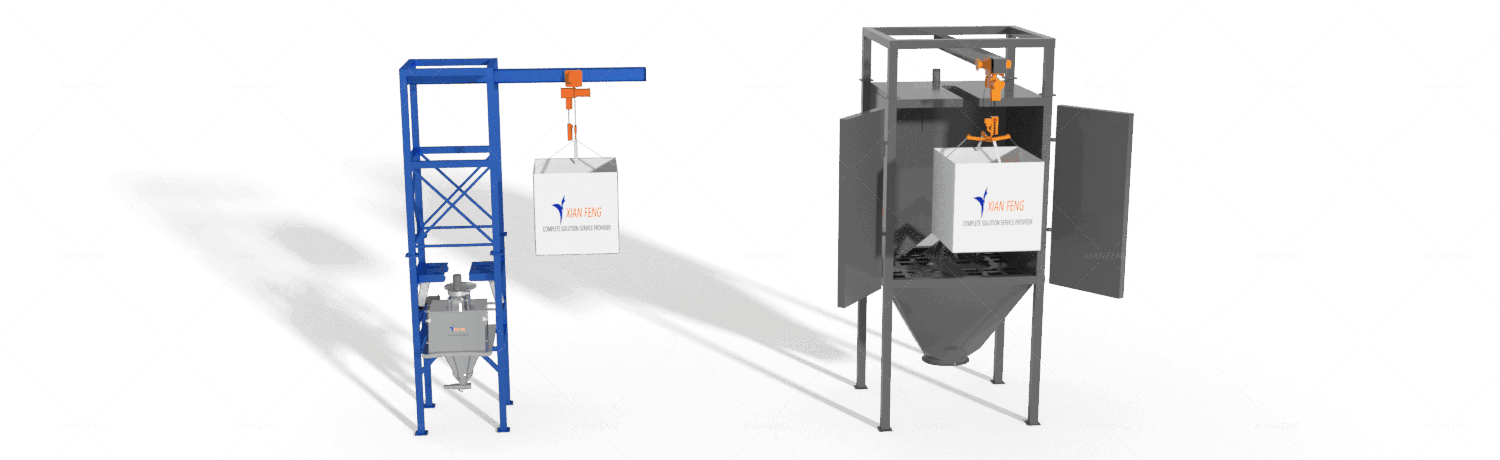

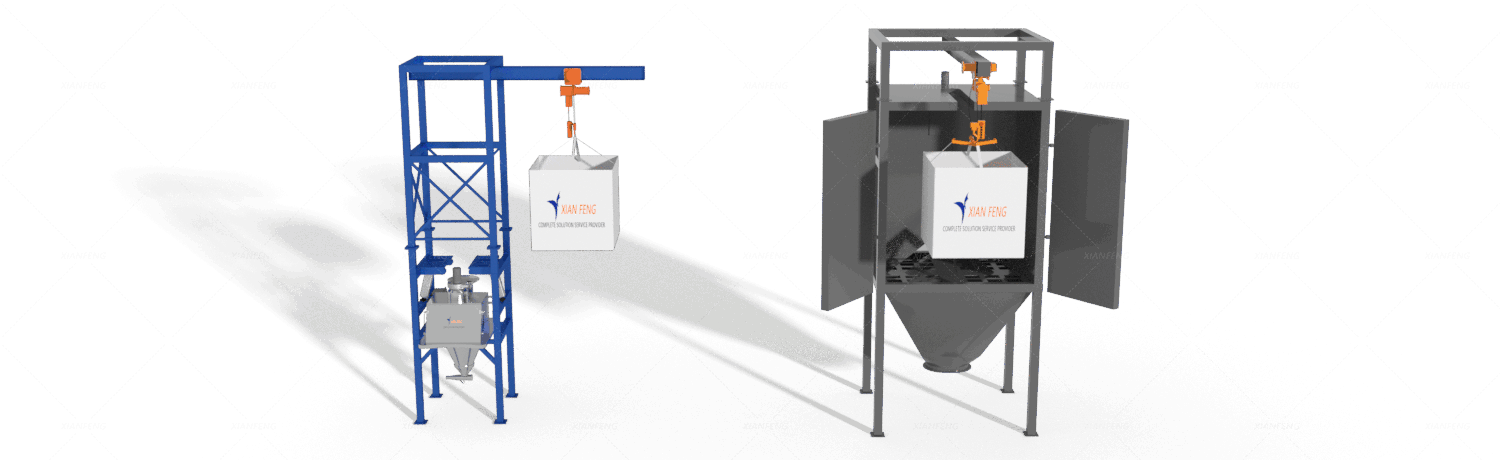

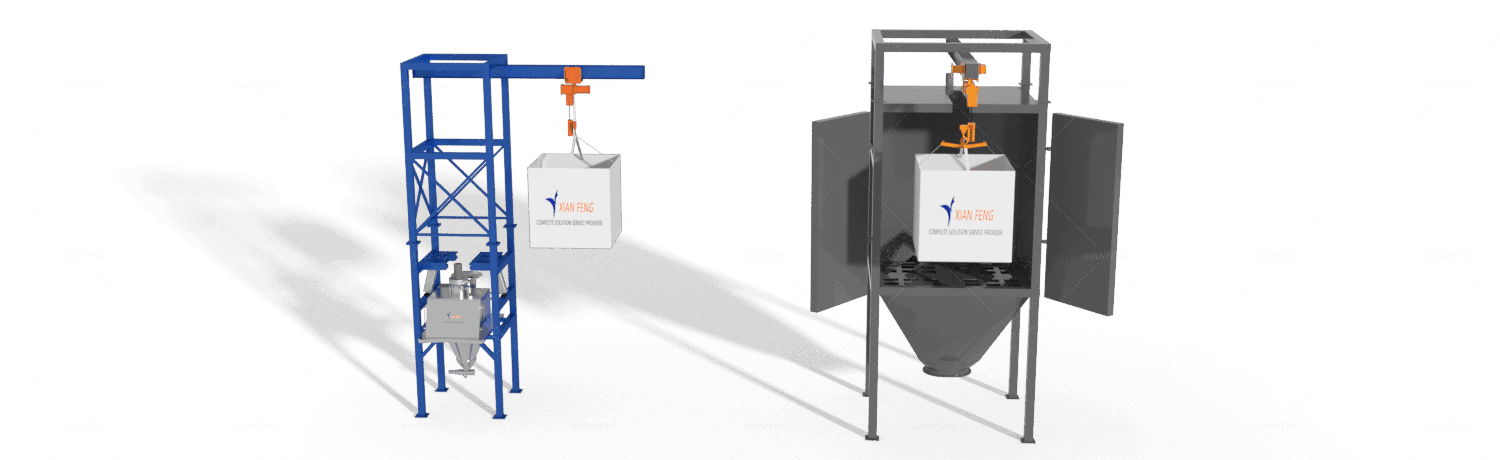

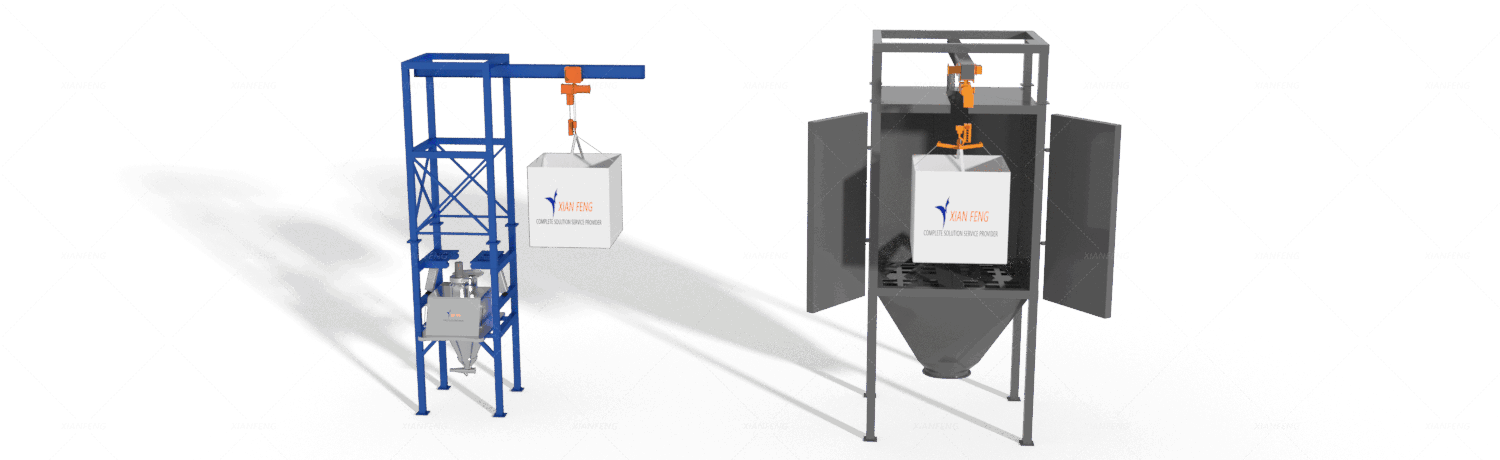

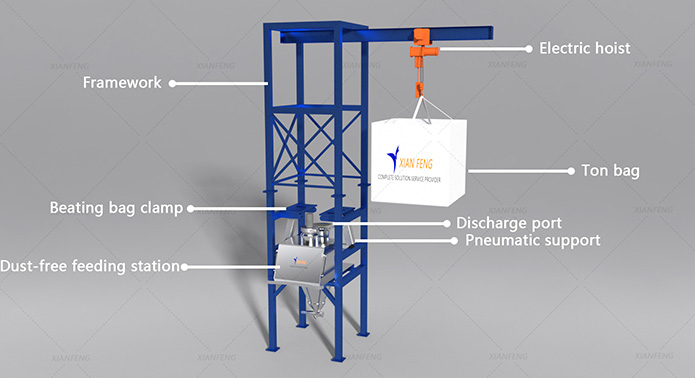

A bulk bag unloader, also known as a bulk bag discharger, is a large bag that is lifted by an electric hoist to transport bulk materials. It is used for industrial dust-free feeding and conveying of granular or powder materials. This equipment is available in two types: open and closed. The XianFeng bulk bag unloading system can be customized according to your needs to achieve manual or fully automatic system loading and unloading and adapt to various processing equipment, providing you with a complete set of customized particle and powder industrial production line solutions.

PVC powder, calcium carbonate, talcum powder, carbon black, etc

powdered sugar, powdered milk, vitamin powder, essence and spices, etc

cement, plaster powder, fly ash, kaolin, etc

pharmaceutical raw material powder, catalyst, etc

lithium iron phosphate, ternary materials, graphite powder, etc

ABS granules, PE resin, rubber additives, etc

quartz sand, aluminum powder, iron powder, etc

corn kernels, feed additives, etc

Electric hoist

hook type

framework

Pneumatic auxiliary unloading device

auxiliary equipment

Matching components

1-3t high-capacity electric hoist, remote control

High operational accuracy, supporting fixed-point feeding

Customizable safety features such as overload protection, limit switches, and emergency braking

The hook can directly hang a ton bag

It can be equipped with either a fixed or adjustable cross frame for mounting, compatible with different types of ton bags.

Customizable in stainless steel or carbon steel as per requirements.

XIAN FENG utilizes thickened plates, and the height of the ton bag unloading station can be customized according to the actual situation of the factory building.

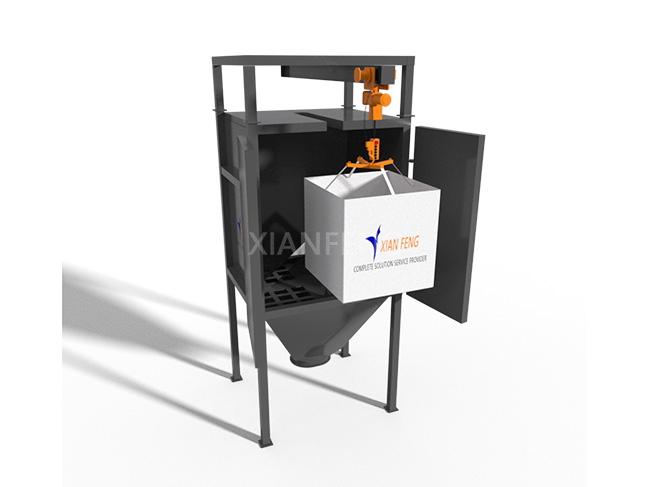

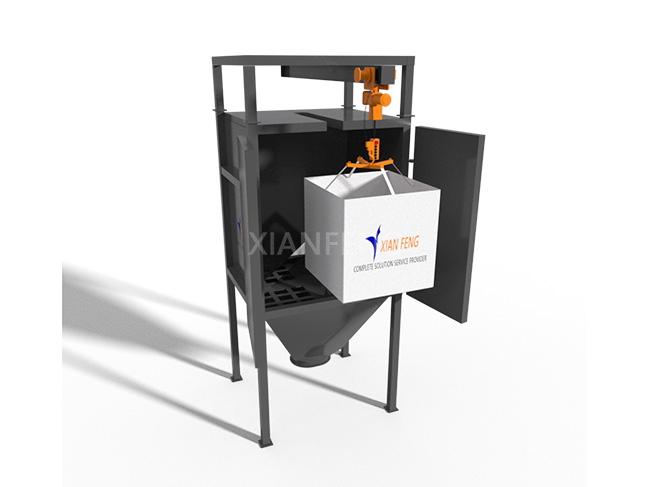

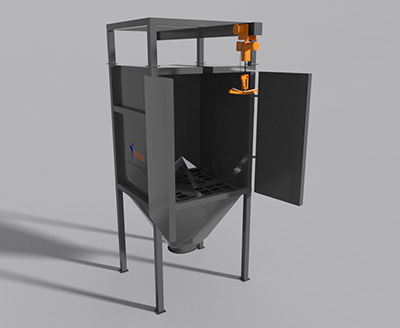

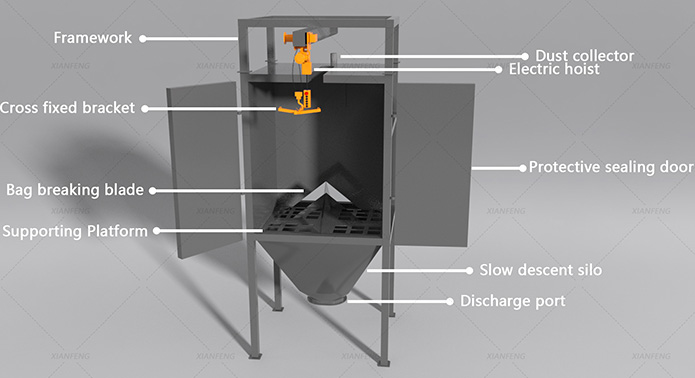

The ton bag unpacking machine adopts a closed enclosure design to prevent powder spillage.

Tonnage bag feeding stations commonly use bag-clamping devices to assist in unloading tonnage bags

Tonne bag unpacking machines commonly use squeezing devices to assist in unloading the tonne bags

Different auxiliary equipment can be equipped below the ton bag feeding station, such as a dust-free feeding station to form a dual-purpose unloading station for both ton bags and small bags, equipped with a vibrating screen for direct screening after unloading.

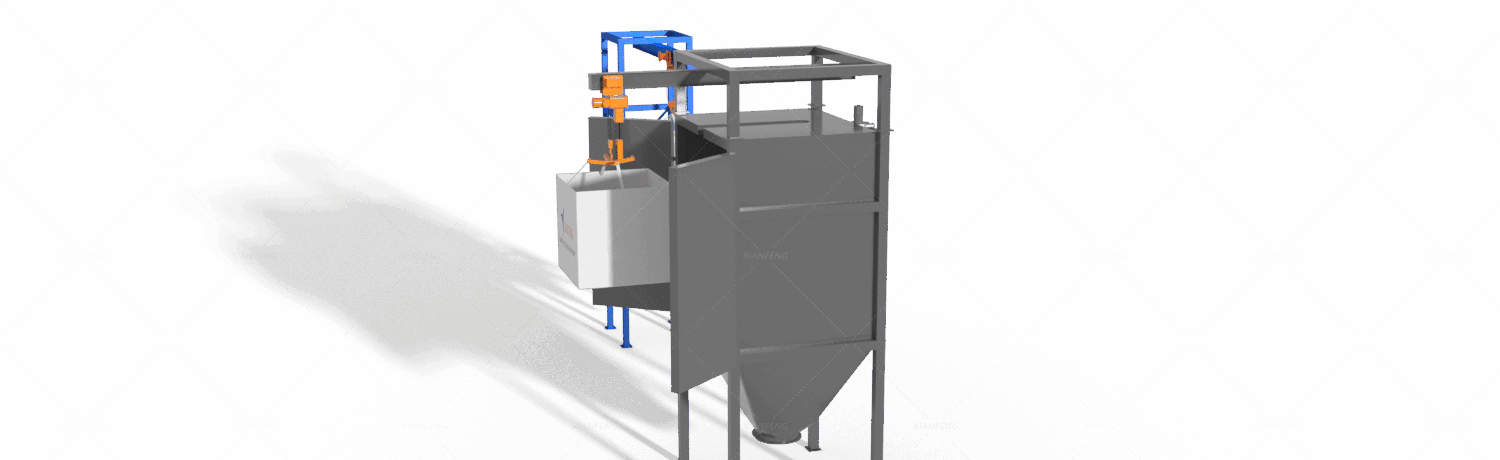

After the internal blade of the ton bag unpacking machine completes the bag breaking, the lower material bin can be customized with auxiliary equipment such as a spiral conveyor.

It can be paired with a suction adapter to connect to a vacuum feeder, enabling conveyance after unloading

It can be matched with flanges, discharge rotary valves, etc. to complete the connection with downstream equipment

Can be paired with a dust collector to achieve dust-free discharge

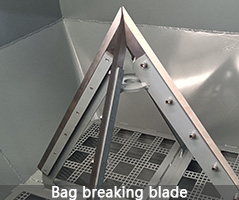

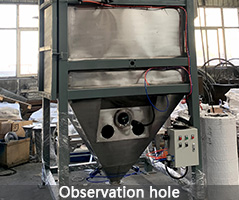

The working principle of the open-type ton bag feeding station is to transport the ton bag to the front of the feeding station using a forklift or a transport vehicle. The operator then controls an electric hoist through a remote control device to lift the bulk ton bag material onto the unloading platform, manually controls the bag opening, and cooperates with a bag clamping and beating device to assist in the unloading of the ton bag material. The working principle of the ton bag unpacking machine is based on a closed structure, with an internal structure consisting of a bag-breaking blade that controls the ton bag to fall and complete the bag-breaking and unloading process.Usually combined with silos and auger conveyor to assist in production.

Consists of a carbon steel or stainless steel frame and a discharge hopper. The frame is designed to support the weight of ton bags (compatible with specifications ranging from 1000-2000kg). The hopper can be integrated with a weighing module to facilitate metered feeding, and some configurations include a breaker to handle caked materials

Equipped with an electric hoist or compatible forklift assistance as standard, the dual-track design allows for the installation of two hoists to enhance efficiency. Precise docking of the ton bag to the material receiving port is achieved through hooks or clamping devices.

Dual-mode bag-breaking design - disposable ton bags are precisely cut and sealed using a pneumatic cutter, while recyclable ton bags are unpacked using a mechanical gripper, avoiding blade debris contamination of materials.

The core consists of pneumatic clamps and vibration devices. For viscous or easily bridging materials, it ensures a residual rate of less than 1% through "tapping + vibratory feeding". Coupled with a diaphragm valve, it achieves bag mouth sealing control

Utilizing negative pressure adsorption combined with pulse bag filters, achieving a filtration accuracy of over 99%. Some designs can incorporate a glove box to achieve 100% isolation between dust and personnel

The bottom is equipped with a rotary valve, screw conveyor, or chain conveyor, which can adjust the conveying speed according to demand and seamlessly connect downstream equipment such as reactors and mixers

Equipped with a simple operation panel, it supports manual/semi-automatic switching. Some high-end models can be integrated into the factory MES system for remote monitoring.

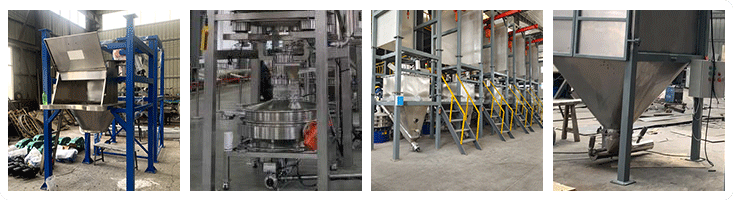

Additive discharge | bulk bag unloader

Flour unloading | bulk bag discharger

Working principle of ton package feeding station

Ton bag unpacking machine

Dimensions: Standard height of 3-4.5 meters, which can be shortened to 2.5 meters (suitable for low-ceilinged factories) or extended to 6 meters (to match high-level storage bins).

Load-bearing capacity: The standard load-bearing capacity is 1-2 tons. For special customizations, detailed communication on specifics can be arranged according to actual needs.

Material: In general, carbon steel with a plastic spraying process is used for ordinary environments. The food and pharmaceutical industry adopts 304 stainless steel. For materials with strong corrosivity, such as chemical solvents, 316L stainless steel can be selected. For special scenarios, customization with lining materials such as polyethylene (PE) or polytetrafluoroethylene (PTFE) is available.

Discharge mode: manual / pneumatic / electric three modes. The basic model is controlled by a manual valve, which can be upgraded to a pneumatic butterfly valve (remote control via button) or an electric knife gate valve (support PLC linkage).

Flow regulation: The discharge port is equipped with a star-shaped discharge valve driven by a variable frequency motor, which can precisely control the material falling speed (stepless adjustment from 0.1 to 2 tons per hour)

Flapping device: Install pneumatic flappers on both sides of the ton bag, which can break up caking through timed pulse impact (frequency 1-5 times/minute) to reduce manual intervention.

Vibrating hopper: Install a vibrating motor (with an amplitude of 0.5-2mm) below the discharge port to facilitate the smooth discharge of materials with poor fluidity, such as damp ore.

Iron removal customization: A permanent magnet bar is embedded in the feed hopper to adsorb ferromagnetic impurities (such as metal debris) in the material, which is suitable for the food and pharmaceutical industries.

Material level monitoring: Install a radar level gauge or ultrasonic sensor in the feeding hopper, which will automatically pause the discharge of material when the material reaches a preset height.

Fault warning: Integrated vibration sensor (monitoring equipment for abnormal noise) and weight sensor (detecting the balance of ton bag suspension) trigger audible and visual alarms and shut down the machine in case of abnormalities.

Safety and environmental protection upgrades: customized explosion-proof design, pulse dust collector, electronic fence warning, hanging bracket anti-fall protection, emergency stop system, and other functions

For more customized features, please contact us directly to discuss the details.

Dust-free feeding station: Equipped with a combination of feeding and unloading functions for both ton bags and small bags.

Vibrating screen: Install a vibrating screen to complete material screening.

Weighing system: Customized quantitative function for weighing silo.

Vacuum conveyor: It conveys materials through negative pressure vacuum.

Dust removal equipment: pulse dust collector

Weighing equipment: belt scale, weighing module (for precise measurement of discharge volume, suitable for batching scenarios);

Mixer and reaction kettle: PLC system integration to achieve full automation of the entire process from "feeding - mixing - discharging".

The core difference between open-type ton bag feeding stations and enclosed bag openers lies in dust control, safety, and cost. The open-type feeding station is a simple, open-platform structure that relies on manual remote feeding and has a lower price. Although it is cost-effective and easy to operate, it cannot completely avoid dust flying. It is mainly suitable for materials such as plastic granules and feed, which are not prone to dust and have low environmental requirements. On the other hand, the enclosed bag opener is a fully enclosed system, usually made in semi-automatic or fully automatic mode. Materials are unloaded in a completely isolated environment through bag cutting, squeezing devices, vibrating devices, etc., and are equipped with high-efficiency dust collectors, which can completely solve the dust problem and ensure employee health and safe production. It is especially suitable for handling powdery, toxic, harmful, or high-value materials such as flour, pharmaceutical raw materials, and chemicals. However, its purchase and maintenance costs are correspondingly higher. Therefore, the key to choosing depends on the characteristics of your materials: if the dust is not large and the budget is limited, the open-type option can be selected; if dust, safety, or environmental protection requirements are involved, the enclosed type is an essential investment.

The blade can be customized according to different needs. The shape can be selected from sawtooth blade, bevel tooth blade, hook blade, or segmented blade to meet various bag-breaking requirements. The custom angle is precisely controlled, and the blade angle will be adjusted according to the hardness of the ton bag material (usually 25°-45°). The material is selected from ordinary chemical and building materials (non-corrosive) alloy tool steel such as Cr12MoV, 304/316L stainless steel for food, medicine, and fine chemicals, tungsten carbide-coated alloy blade for high wear materials such as ore powder, and anti-static coating or grounding design for flammable and explosive materials such as plastic particles and coal powder. The blade can be arranged in multiple layouts according to the size of the ton bag, and other customized requirements can be met.

23 years of experience specializing in screening and conveying equipment manufacturing [Rich experience, providing complete customized solutions]

40,000 square meter factory, a genuine source manufacturer [No middlemen, lower prices]

50 technical patents, CE/ISO certifications [Technology proven, trustworthy]

20 years of export experience, equipment exported to over 70 countries worldwide [Full-process support from a professional team]

Ensure your product quality and reputation.

Our professional solutions are designed to maximize your production efficiency.

Reduce production downtime, resource waste, and maintenance issues.