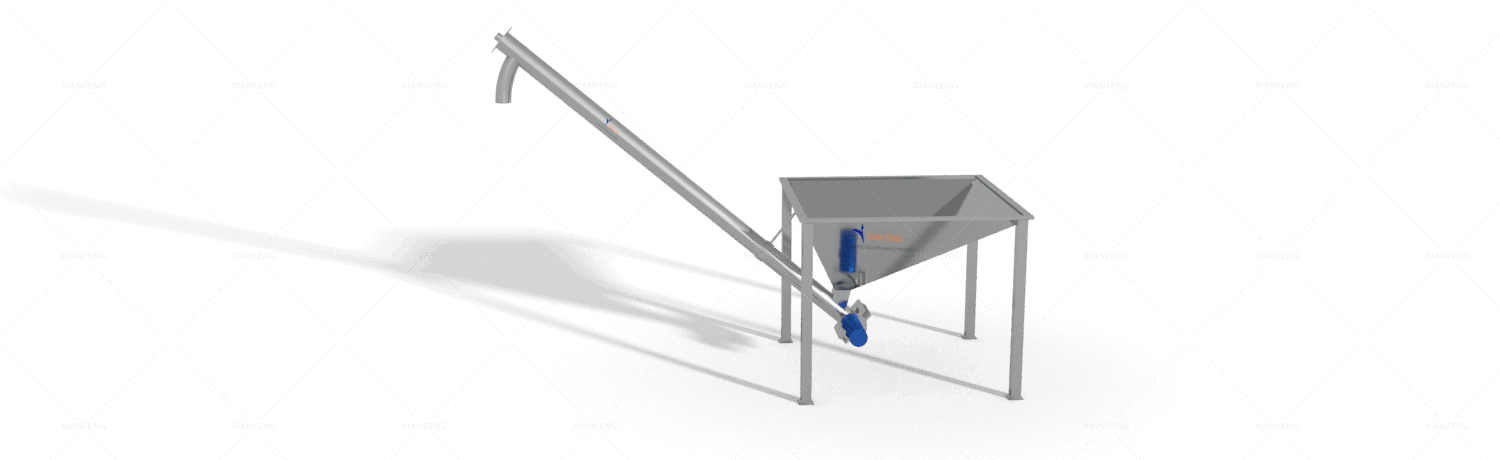

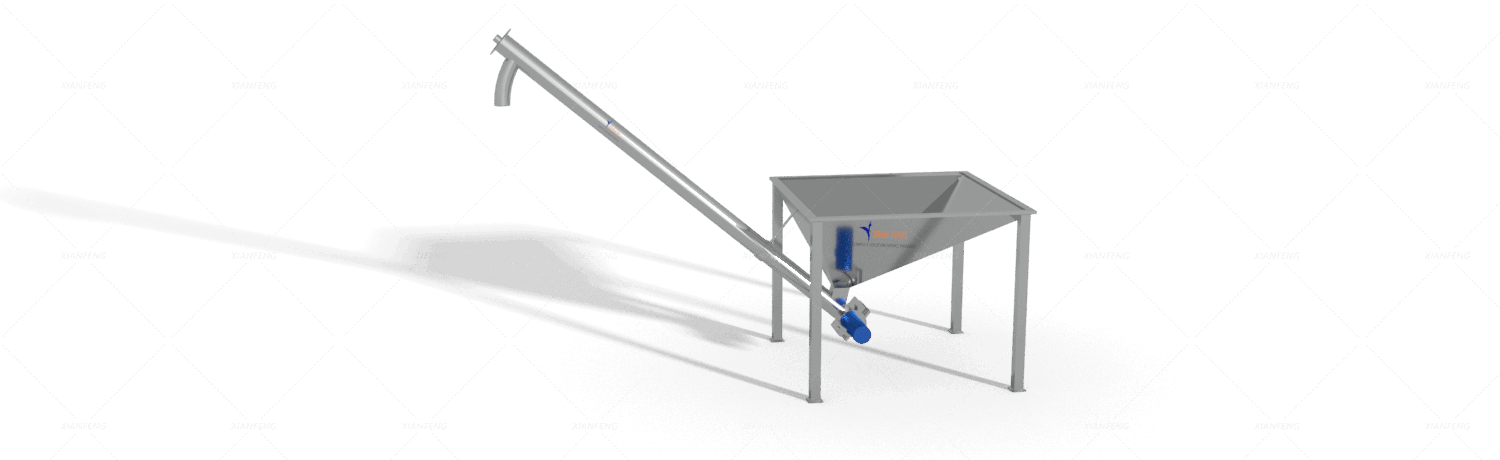

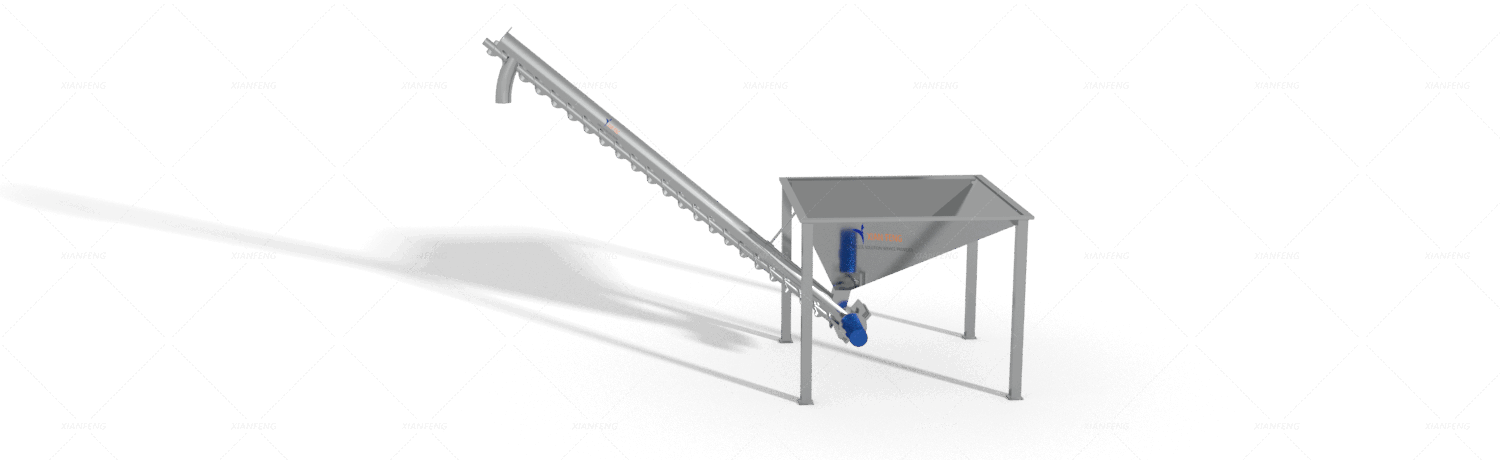

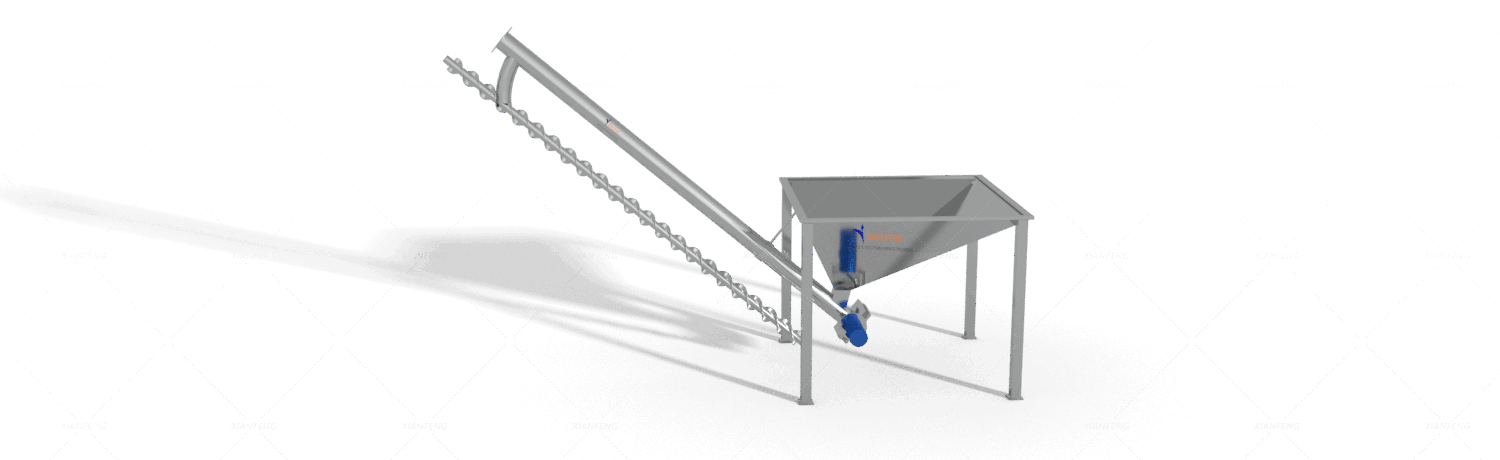

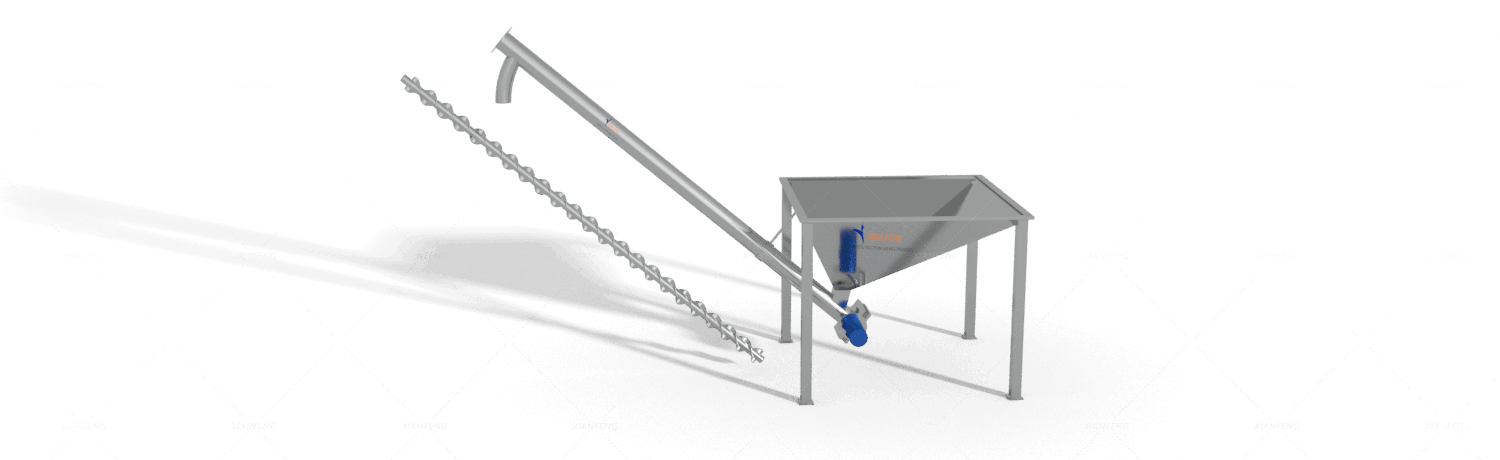

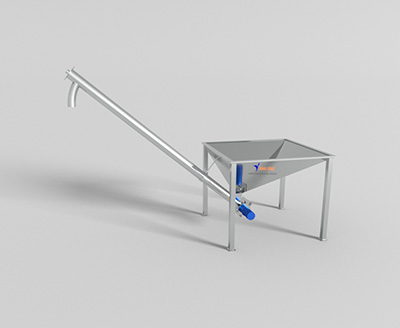

Spiral conveyor, also known as spiral feeder, adopts a tubular structure and is driven by a motor to rotate the spiral blades inside the tube, pushing the material to move along the conveyor groove to achieve material conveying and lifting. It is commonly used for closed conveying and feeding operations of powder or granular materials. It is made of carbon steel and stainless steel materials and is a conveying and feeding equipment with height, length, inclination angle, and pipe diameter that can be customized according to needs.XIAN FENG conveyor can be paired with vibro screener to complete customized industrial production solutions for screening and conveying.

flour, starch, wheat, grain granules, peanuts, beans, seeds, bran, etc

white sugar, salt, monosodium glutamate, milk powder, cocoa powder, coffee powder, tea leaves, nuts, pet food granules, etc

cement, lime powder, gypsum powder, talc powder, fly ash, sand and gravel, slag, perlite, etc

PVC powder, sodium chloride powder, plastic pellets, sodium carbonate, carbon black, urea pellets, sulfur powder, etc

soybean meal powder, fish meal, bone meal, meat powder, feed pellets, alfalfa grass pellets, vitamin premix, etc

dehydrated sludge, printing and dyeing sludge, chemical sludge, wood chips, furnace slag, plastic crushing materials, etc

traditional Chinese medicine powder, antibiotic powder, vitamin powder, starch, lactose, microcrystalline cellulose, pharmaceutical pills, medicinal pigment granules, etc

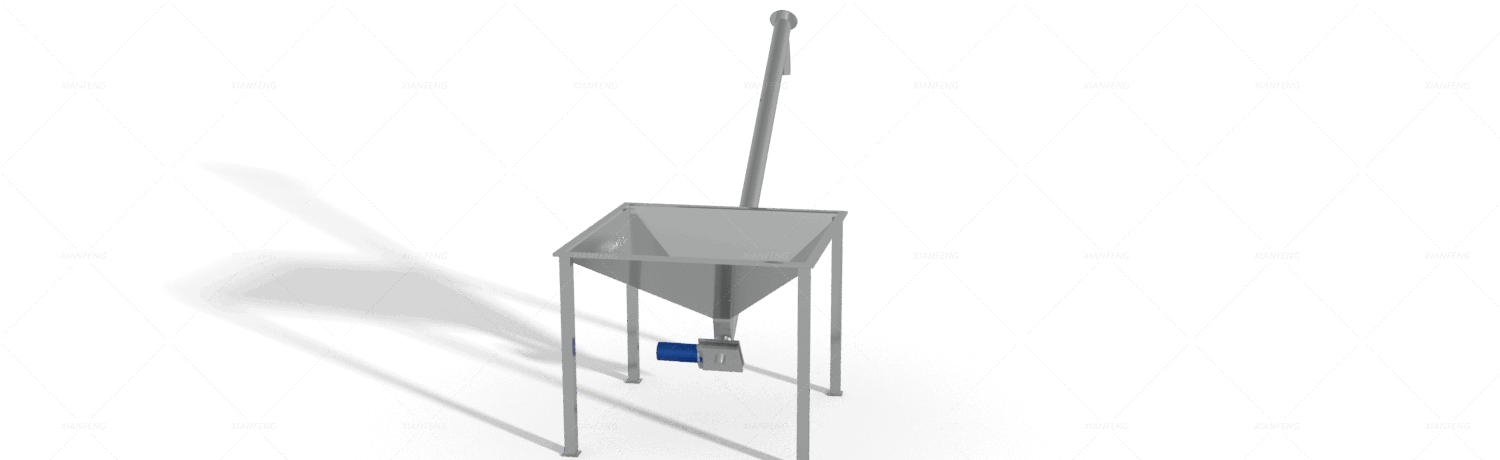

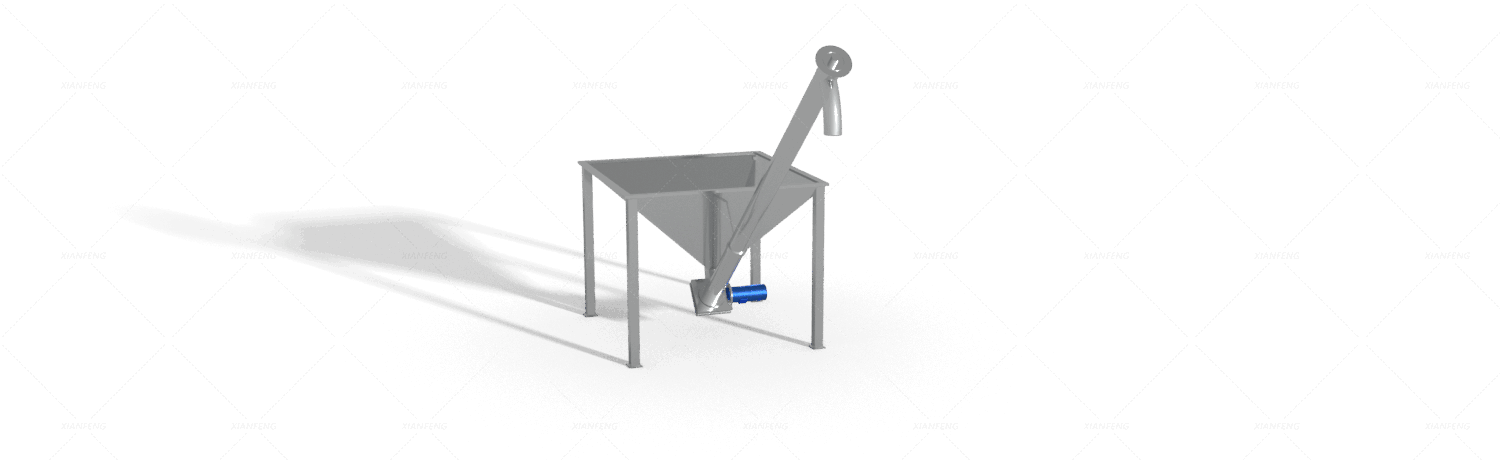

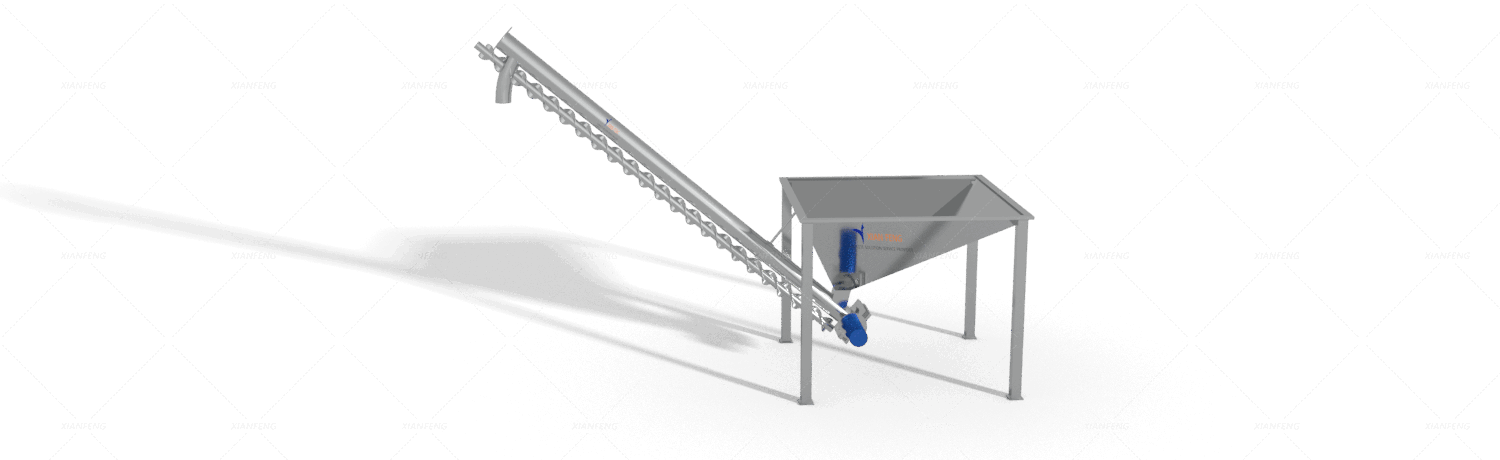

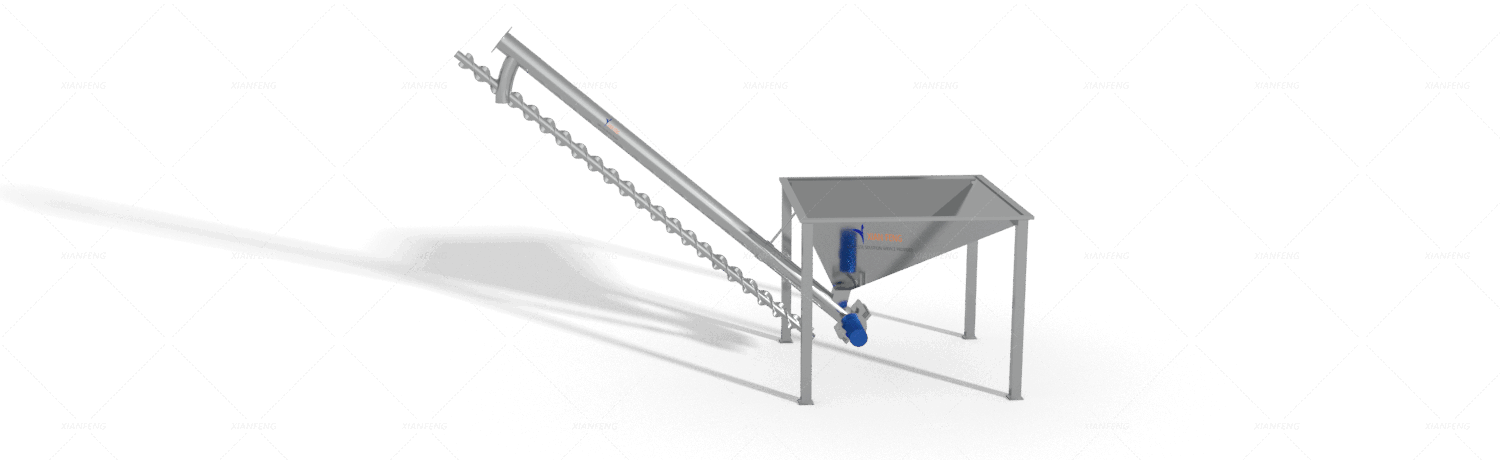

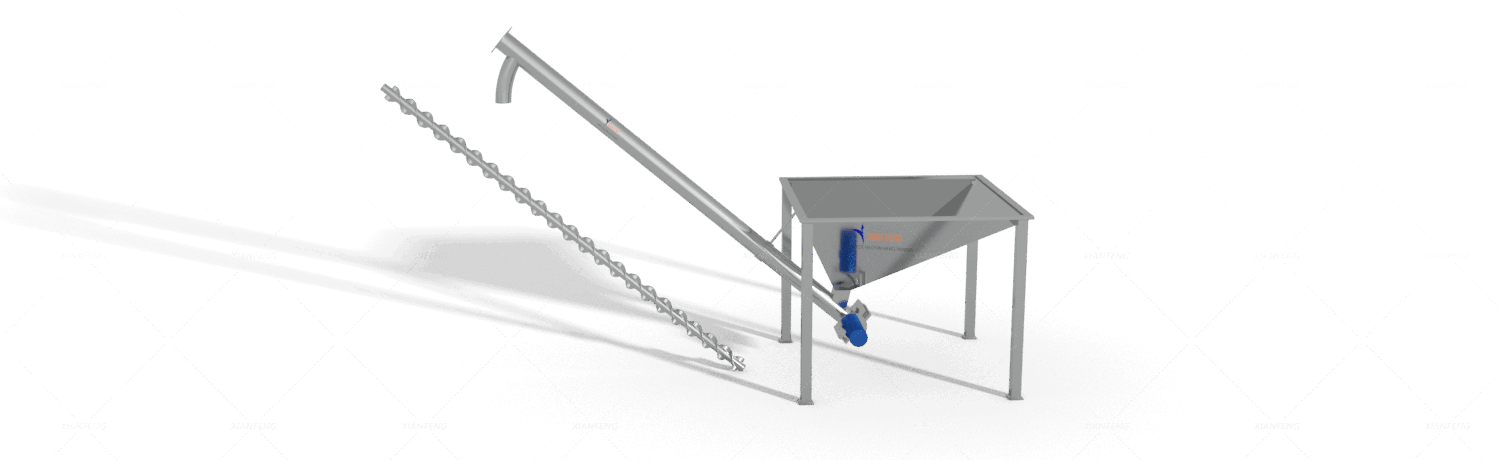

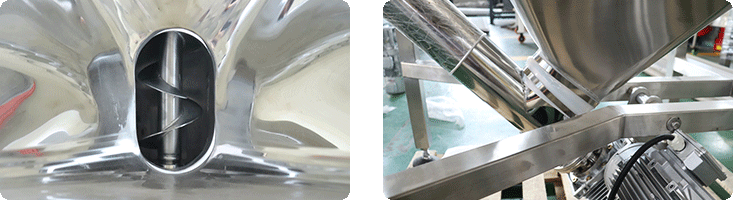

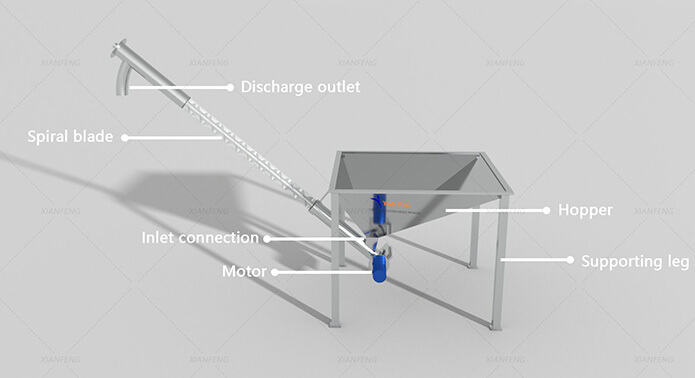

Discharge outlet

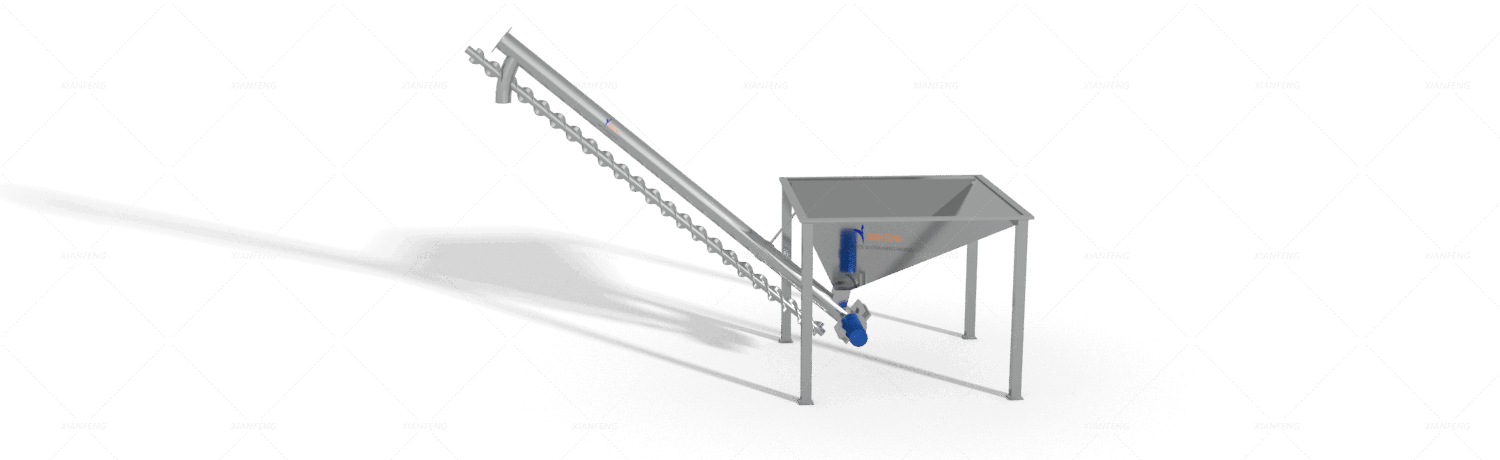

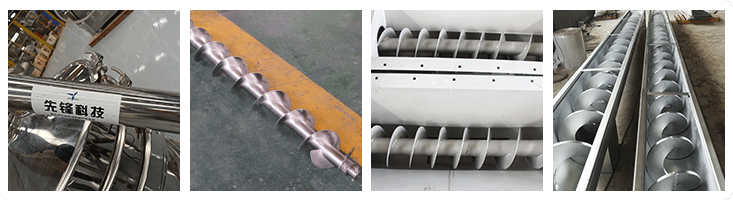

Conveyor pipeline and spiral blades

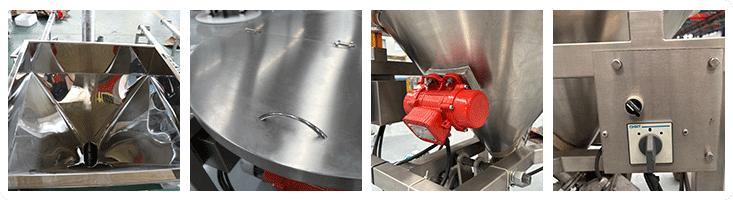

Cache hopper

Feed inlet

Equipment leg

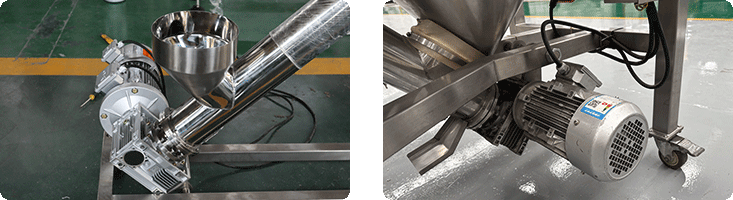

Motor

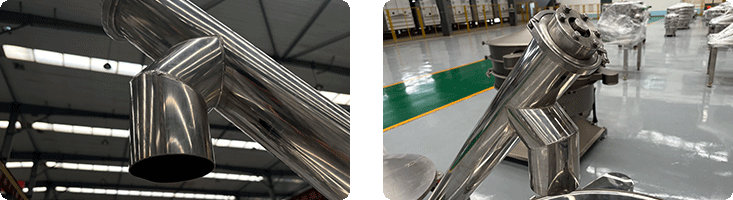

The discharge port is polished smooth without burrs and does not contaminate the material.

The bearing interface has precise docking dimensions, and the spiral rod rotates smoothly to transport materials evenly.

The pipe diameter can be customized as needed to meet different production requirements.

304/316 stainless steel or carbon steel material is optional.

Spiral blades with and without shafts are available in two specifications to meet different material requirements.

The hopper adopts fish scale welding technology, finely polished without burrs, and sealed without leakage.

The hopper can be equipped with dust covers as needed to prevent dust from flying.

Customizable warehouse wall vibrators can assist in cutting and maintaining smooth feeding.

The feeding port is polished smooth and the feeding is smooth.

The connection can be sealed with food and pharmaceutical grade silicone to meet the production standards of the food or pharmaceutical industry.

The tilt angle can be adjusted to meet production requirements at different heights.

The base is made of thickened high steel material for stable support.

Adopting variable frequency speed reduction motor to meet different production requirements.

Different from vacuum conveying system for powder,Spiral conveyor is a continuous conveying equipment that pushes materials by rotating the blades on the spiral shaft, and is divided into two types: with shaft and without shaft. The working principle is that the motor drives the spiral shaft to rotate. After the material enters from the feeding port, it is pushed by its own weight and frictional resistance in horizontal conveying, and lifted by centrifugal force in vertical conveying. Axial type is suitable for dry powder and small particle materials, while non axial type is suitable for viscous and easily entangled materials. This device is widely used in the fields of building materials, grain processing, chemical engineering, and environmental protection, but it is not suitable for materials with high viscosity and easy clumping

composed of an electric motor, a reducer, and a coupling, providing rotational power

The core component, including a spiral shaft and spiral blades welded onto it, that drives the material forward

typically designed in a U-shaped or tubular form, accommodating a spiral body and protecting internal mechanisms

including head bearings, tail bearings, and suspension bearings (for long distances), supporting the spiral shaft

controls the input and output of materials, and designs reasonable shapes and sizes according to requirements

| Model | Tube Dia. (mm) | Helix pitch(mm) | Speed(r/min) | Capacity(m³h) |

| LS102 | φ102 | 80 | 50~130 | 1~2 |

| LS127 | φ127 | 100 | 50~130 | 1.5~3 |

| LS159 | φ159 | 128 | 50~130 | 5~8 |

| LS219 | φ219 | 175 | 50~130 | 10~15 |

| LS273 | φ273 | 215 | 50~130 | 15~20 |

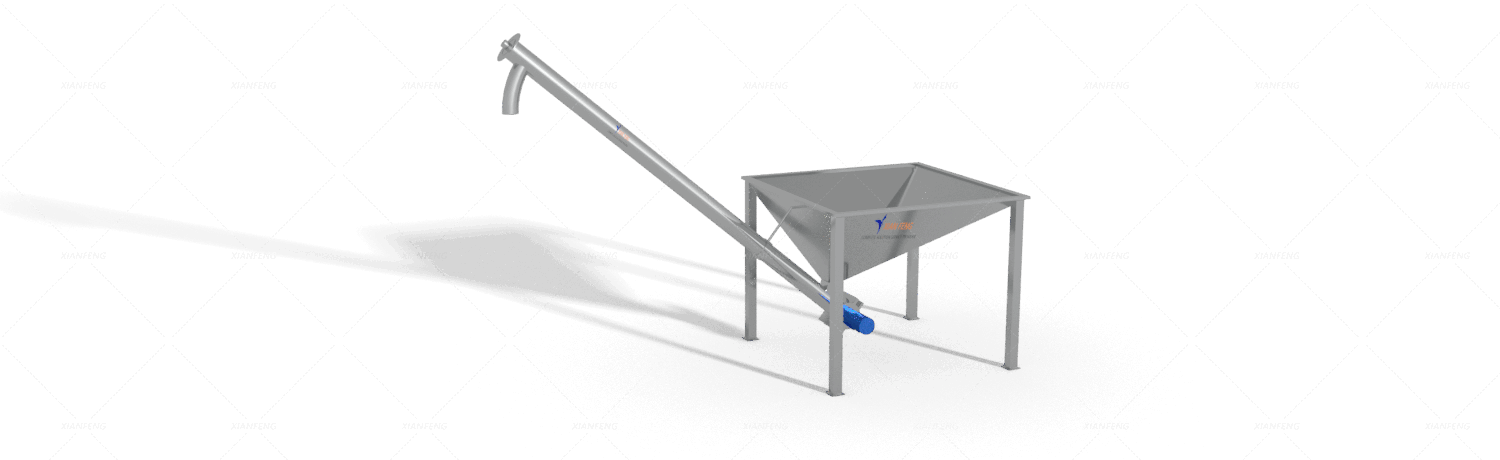

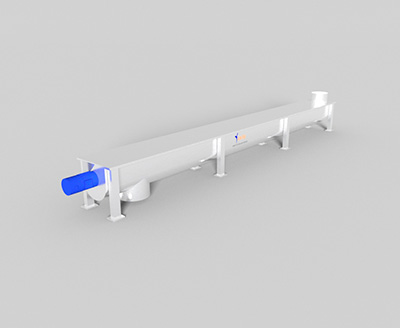

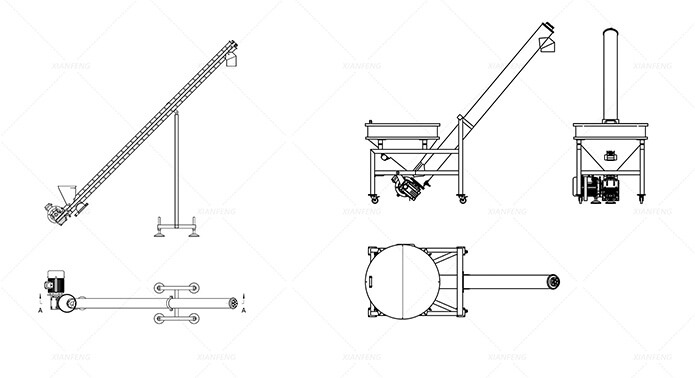

Horizontal screw conveyor

Structure: The casing is mostly U-shaped or tubular, with spiral shafts arranged horizontally, and the conveying path is straight and horizontal. Double axis spiral can also be customized according to demand to meet production requirements.

Features: Short conveying distance (usually ≤ 30m), low conveying resistance, low energy consumption, and simple maintenance.

Applicable scenarios: Horizontal transportation of powdered (such as flour and cement) and granular (such as grains and plastic particles) materials at close range, commonly used in "horizontal material transfer" in food, chemical, and building materials workshops.

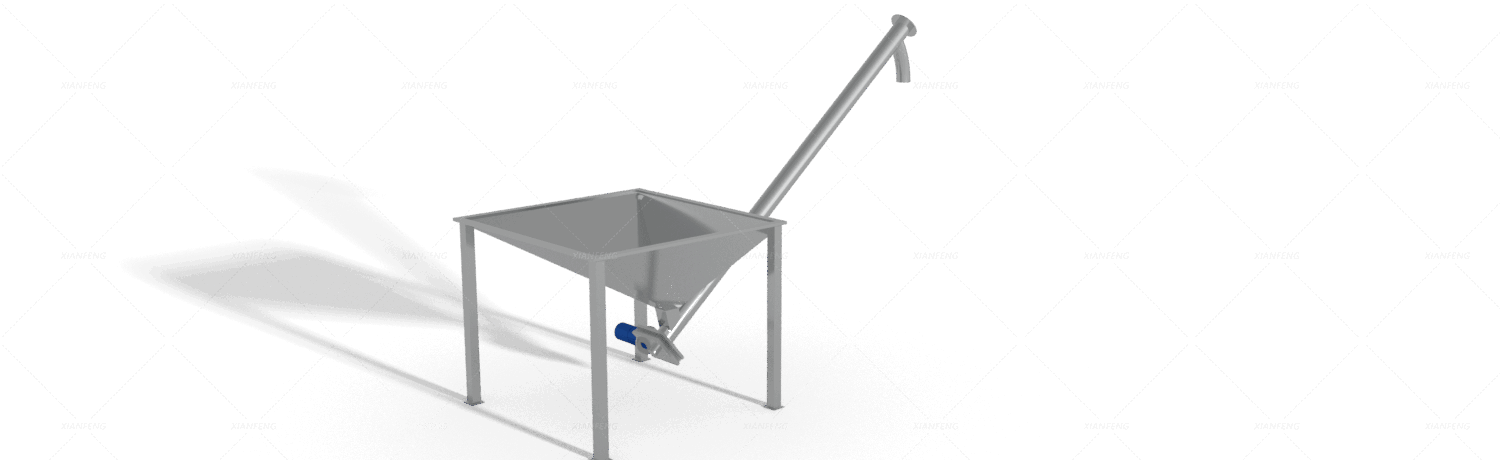

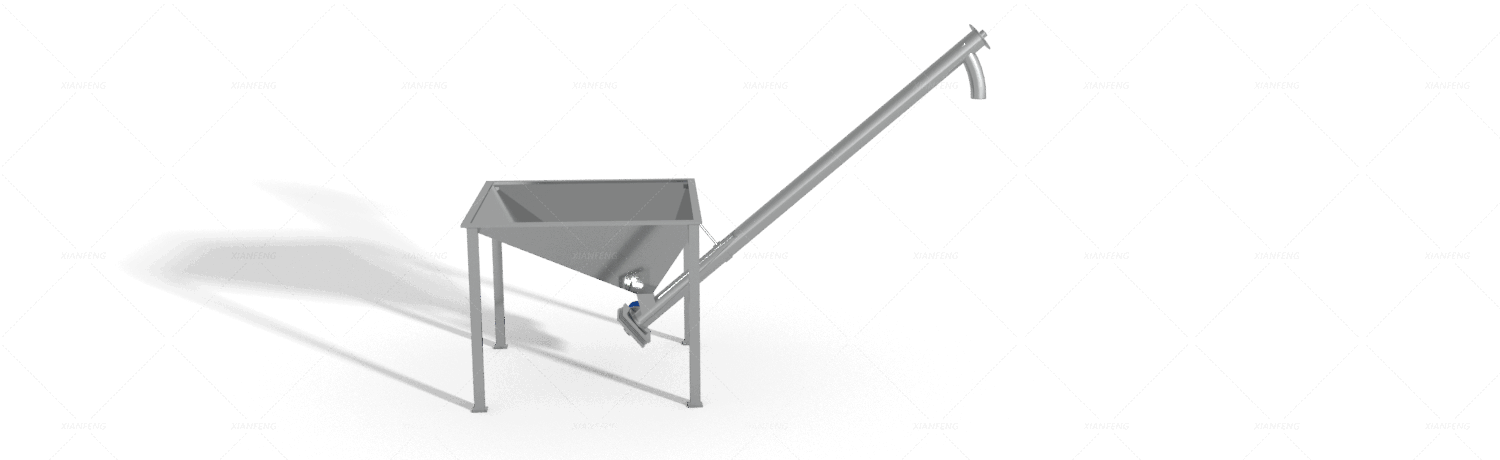

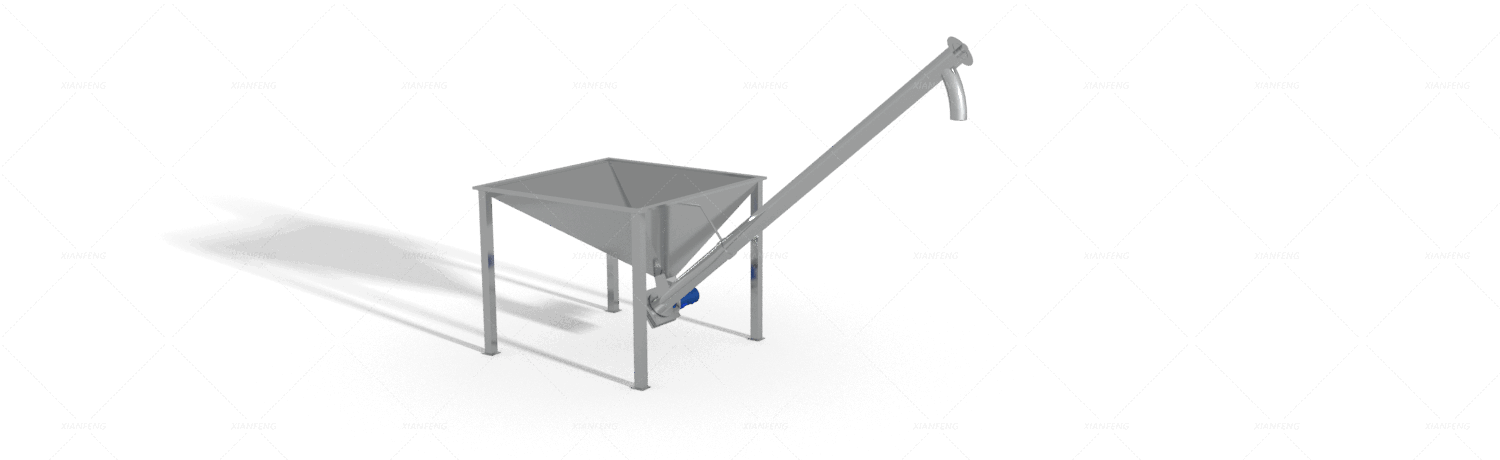

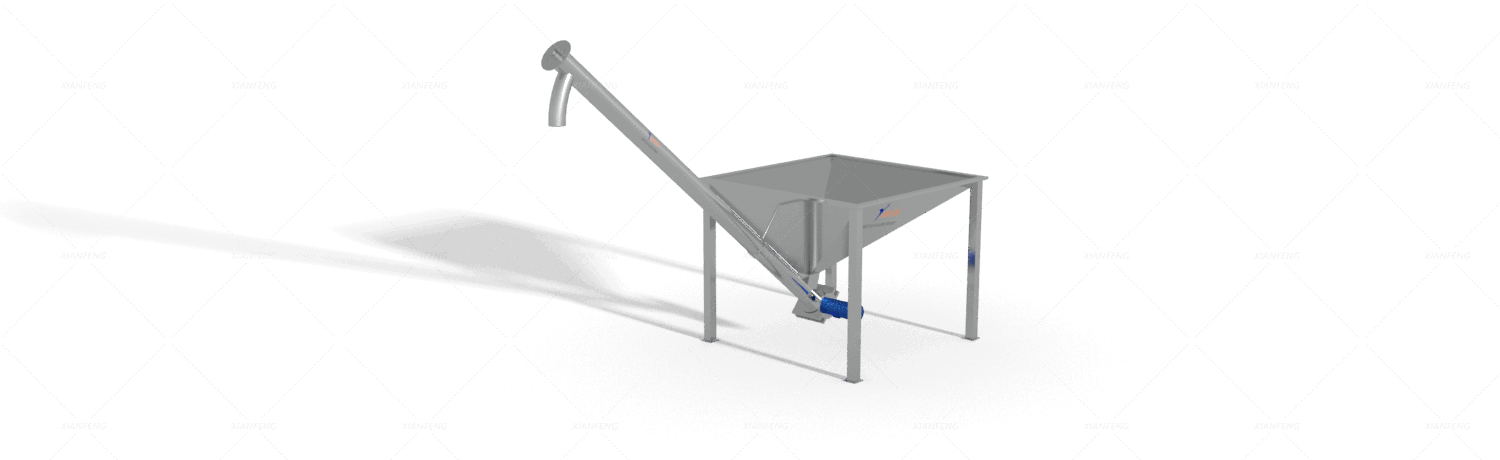

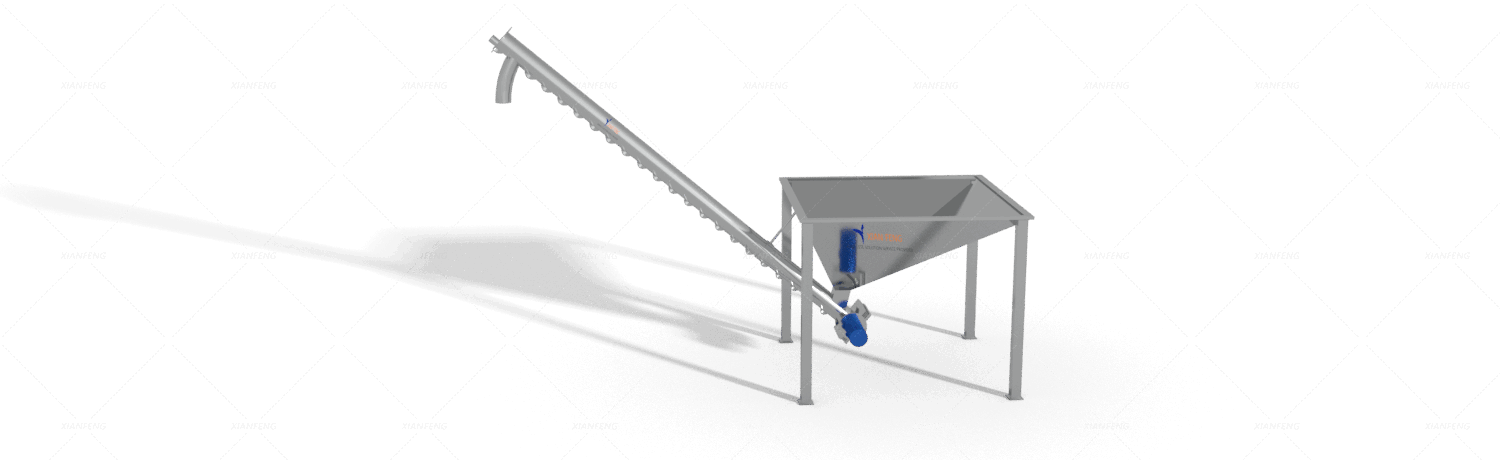

Inclined screw conveyor

Structure: The spiral axis forms a certain angle with the horizontal plane (usually ≤ 45 °, excessive angle can cause material to slide down and the conveying efficiency to drop sharply), and the casing is mostly enclosed.

Features: Balancing the advantages of horizontal and vertical transportation, it can cross small obstacles such as equipment and channels.

Applicable scenarios: Scenarios that require "oblique lifting/lowering", such as inclined feeding from the ground to the silo in grain warehouses, and material connection between equipment at different heights in chemical production lines.

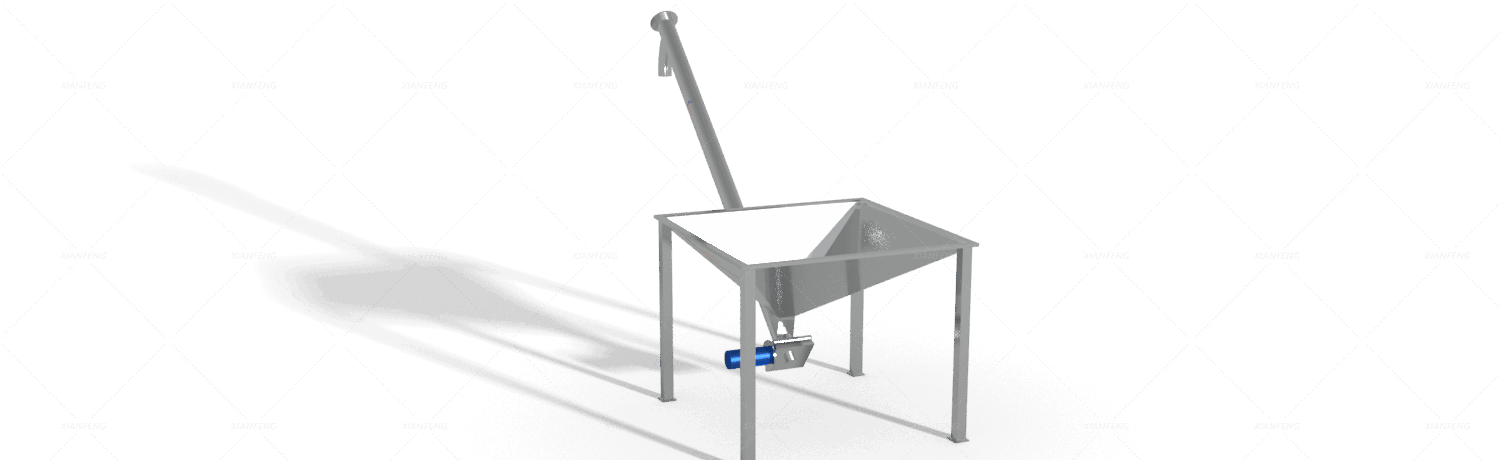

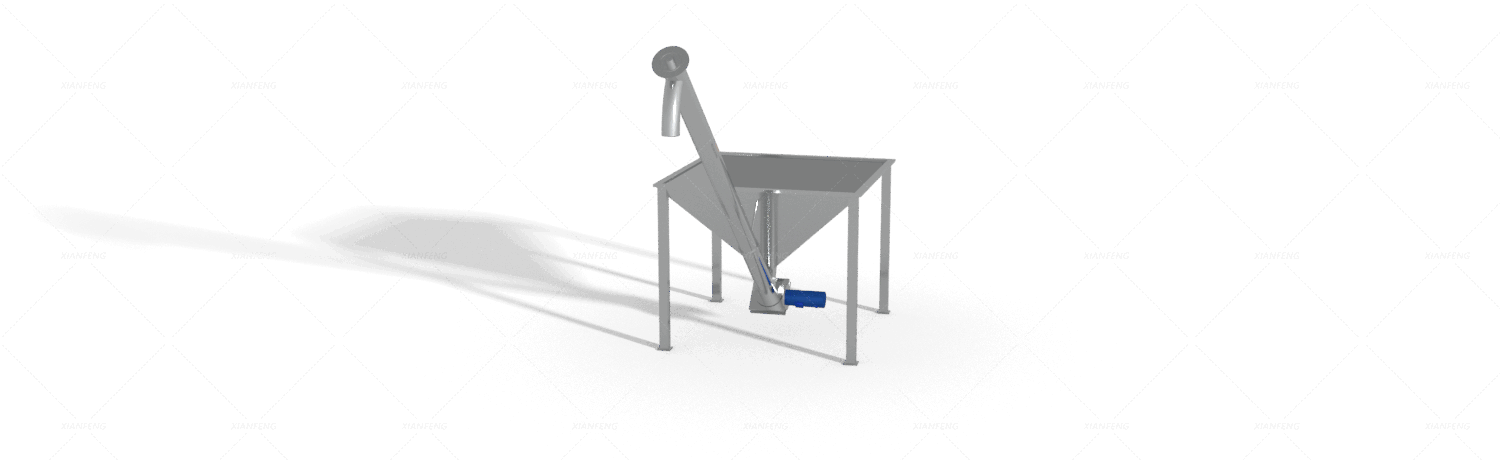

Vertical screw conveyor

Structure: The spiral shaft is arranged vertically, and the casing is cylindrical (enclosed) with a feed inlet at the bottom and a discharge outlet at the top. Some models may be equipped with an "anti reflux device" to prevent material from sliding down.

Characteristics: Small footprint, limited vertical conveying height (usually ≤ 8m), high requirements for material flowability (to avoid clumping and wall sticking).

Applicable scenarios: tight space and the need for "vertical lifting", such as feeding from the bottom hopper to the top mixer in a feed mill, and vertical material transfer in a pharmaceutical workshop.

The selection should revolve around three core factors: material characteristics, conveying requirements, and working conditions, with specific attention to three points:

Material adaptation: For powders/small particles (such as flour, cement), choose ordinary spiral with a shaft; Easy to entangle/sticky/block materials (such as wet sludge, broken tree branches), choose shaftless spiral (to avoid shaft jamming); High hardness materials (such as gravel and ore) require wear-resistant blades (made of manganese steel).

Transport parameters: For horizontal transport, priority should be given to standard pitch axial helix; For inclined conveying (angle ≤ 20 °, material is prone to slip if it exceeds 20 °), it is necessary to increase the pitch or add anti slip lining plates; Vertical conveying requires the selection of "large lead screw" or "belt screw" and matching with high torque drive.

Working condition requirements: Choose 304 stainless steel body and food grade lubricating grease for the food/pharmaceutical industry; For scenes with high dust (such as coal powder transportation), choose a closed tubular spiral (dust prevention); High temperature environments (such as dried materials) require the selection of high-temperature resistant bearings and blades (such as heat-resistant steel).

23 years of experience specializing in screening and conveying equipment manufacturing [Rich experience, providing complete customized solutions]

40,000 square meter factory, a genuine source manufacturer [No middlemen, lower prices]

50 technical patents, CE/ISO certifications [Technology proven, trustworthy]

20 years of export experience, equipment exported to over 70 countries worldwide [Full-process support from a professional team]

Ensure your product quality and reputation.

Our professional solutions are designed to maximize your production efficiency.

Reduce production downtime, resource waste, and maintenance issues.