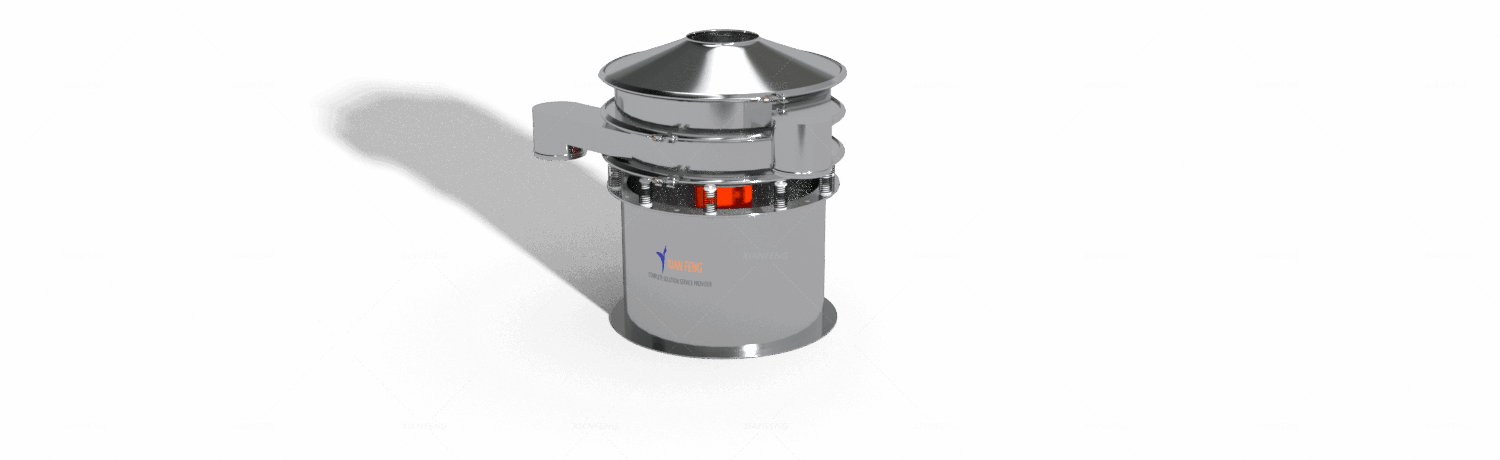

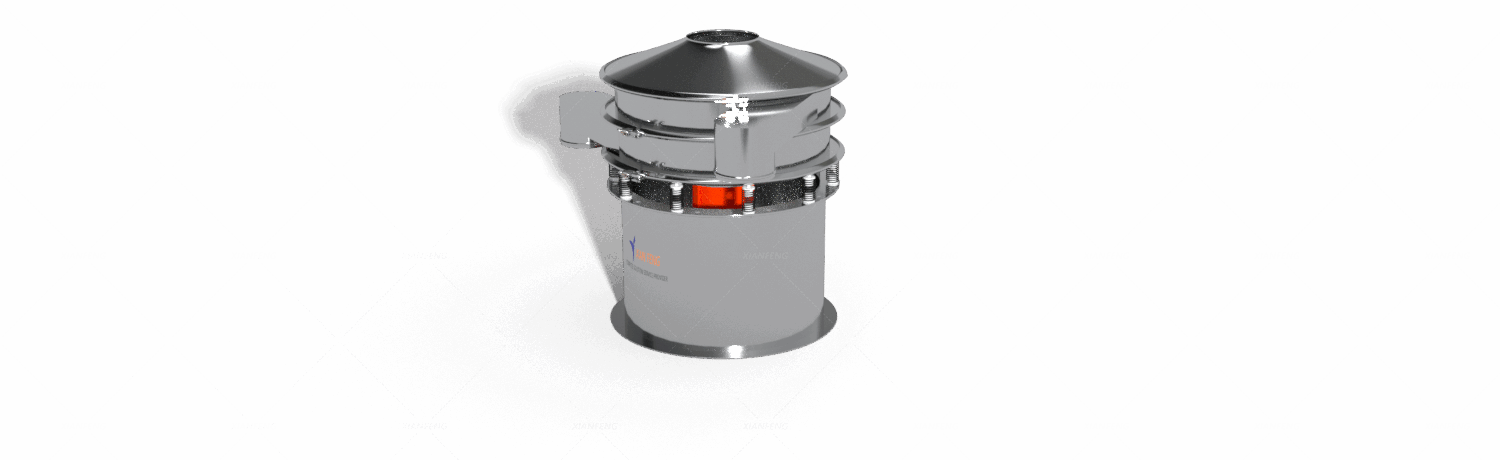

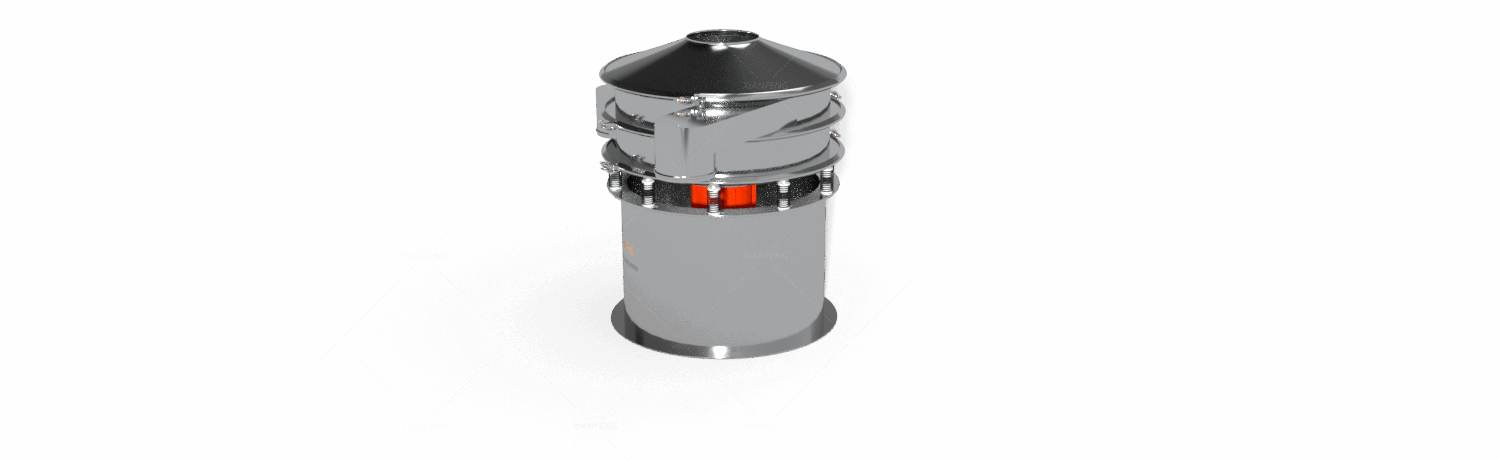

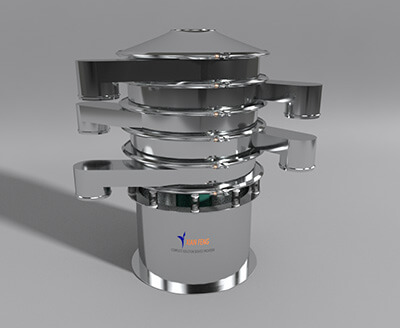

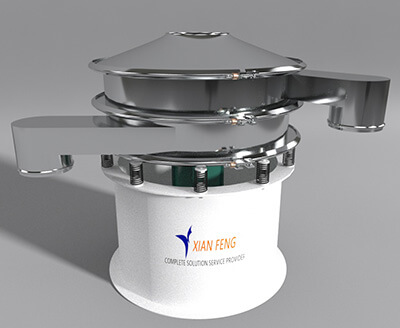

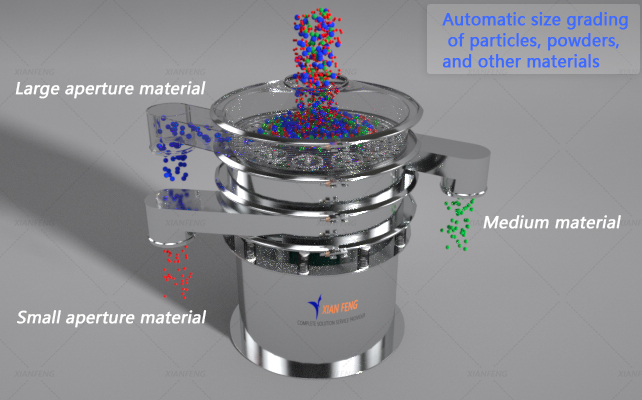

Circular vibratory separators are versatile screening machines suitable for sifting, filtering, and removing impurities from powders, granules, liquids, and other materials. They are applicable across industries including Food, Pharmaceutical, Chemical, New Materials, and Metallurgy.Featuring a stackable configuration of up to five decks for simultaneously screening six particle sizes, these separators offer a simple structure, easy maintenance, compact footprint, and high efficiency. They seamlessly integrate with various upstream and downstream equipment for streamlined production.

Flour, powdered sugar, milk powder, fruit juice, nuts, tea, dried flowers, pet food, etc.

Pills, pills, powders, capsules, intermediates, excipients, etc

Coatings, hydrochloric acid, resin particles, fluorescent powder, nitric acid, sodium hydroxide, sodium carbonate, etc

Coal, quartz sand, lime powder, cement powder, dry sand, soil, glass, talcum powder, etc

Iron powder, copper powder, aluminum powder, tungsten powder, titanium powder, nickel powder, zinc powder, etc

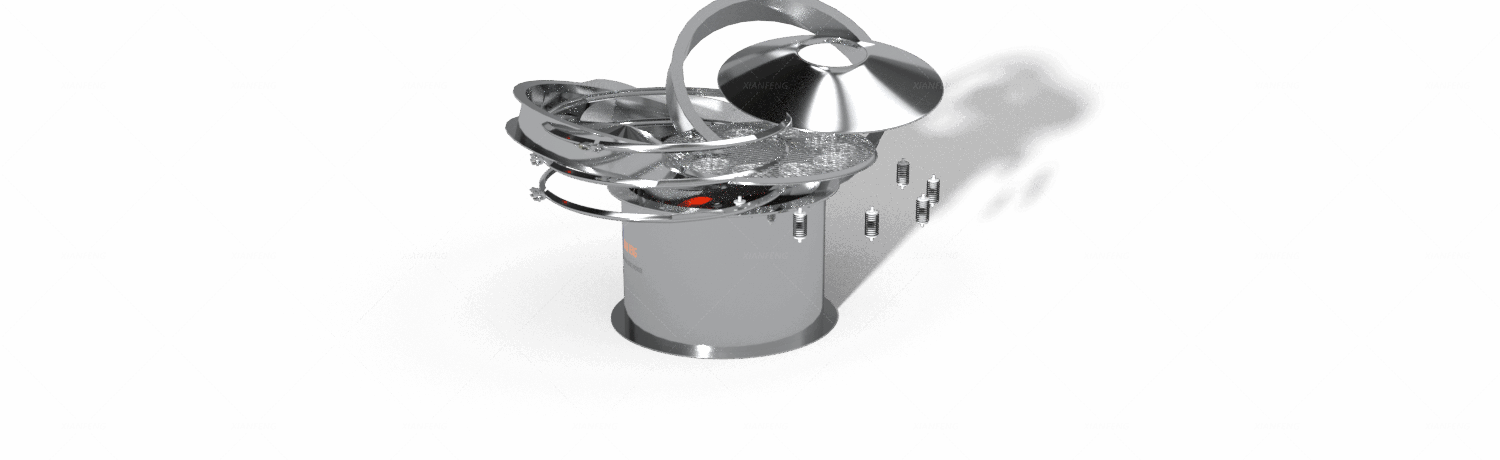

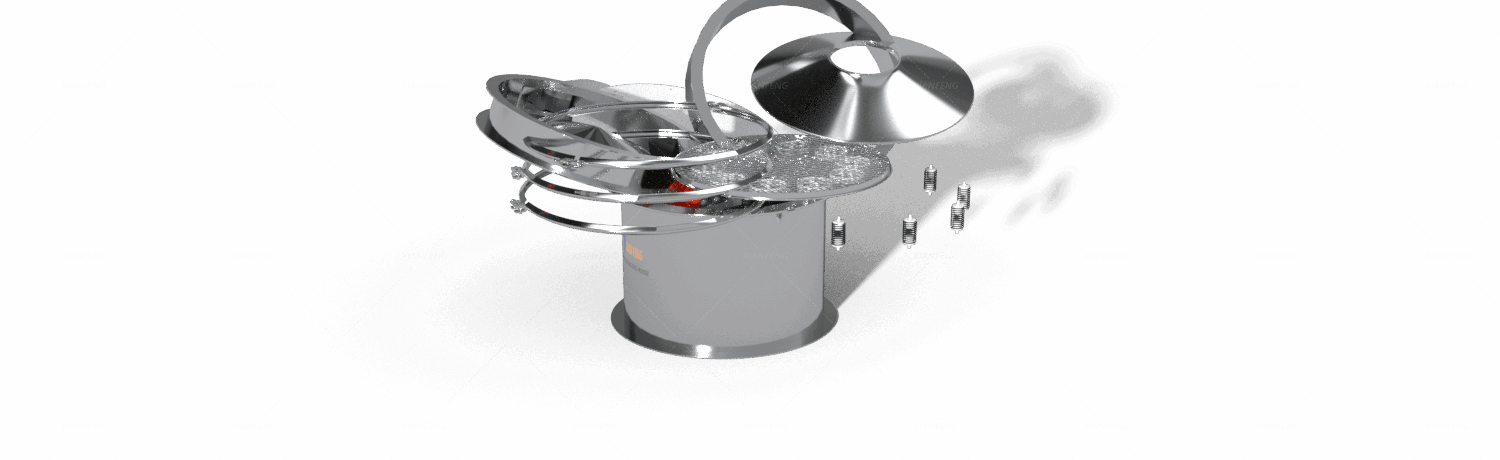

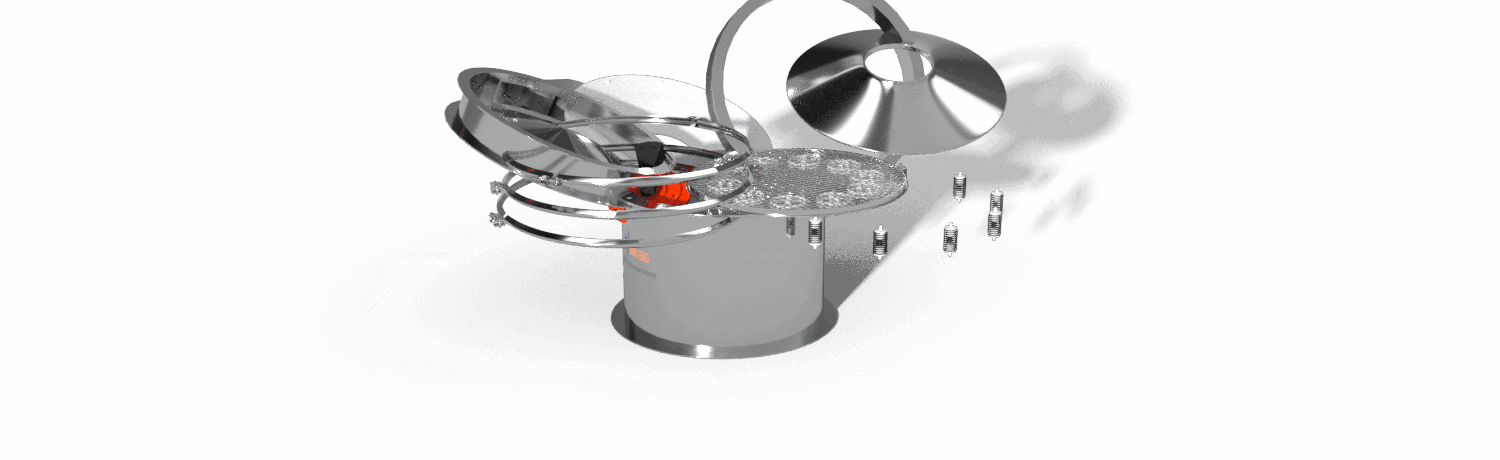

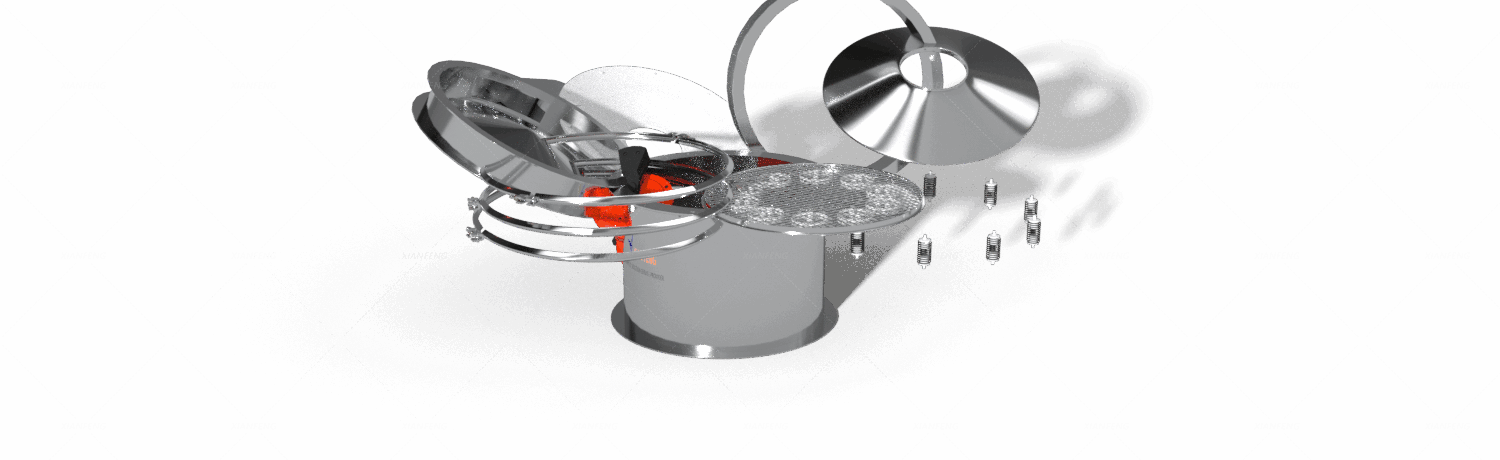

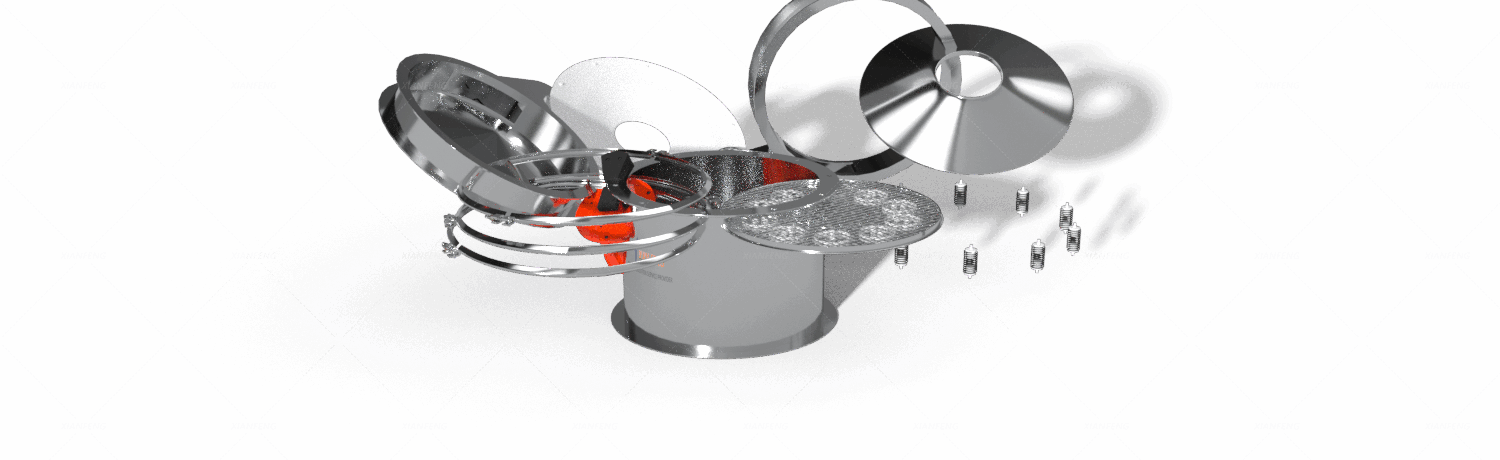

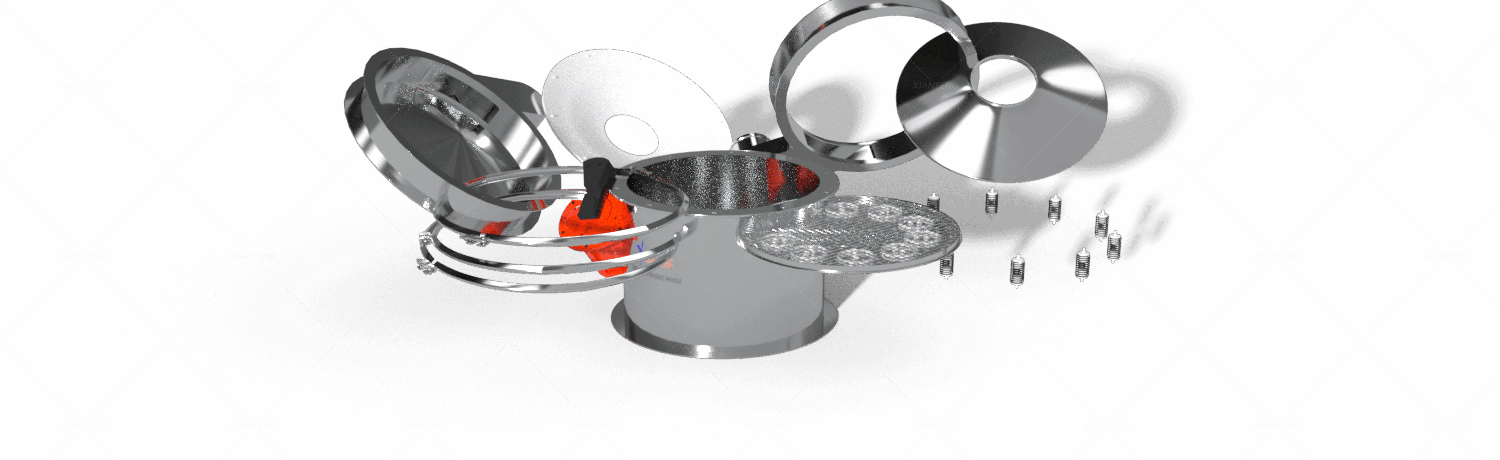

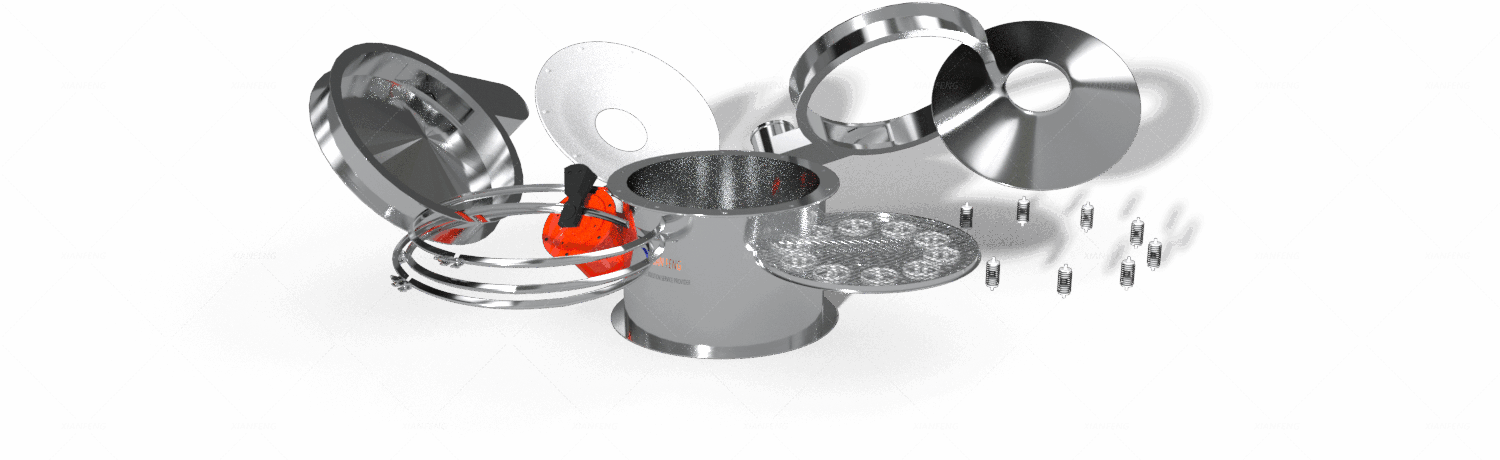

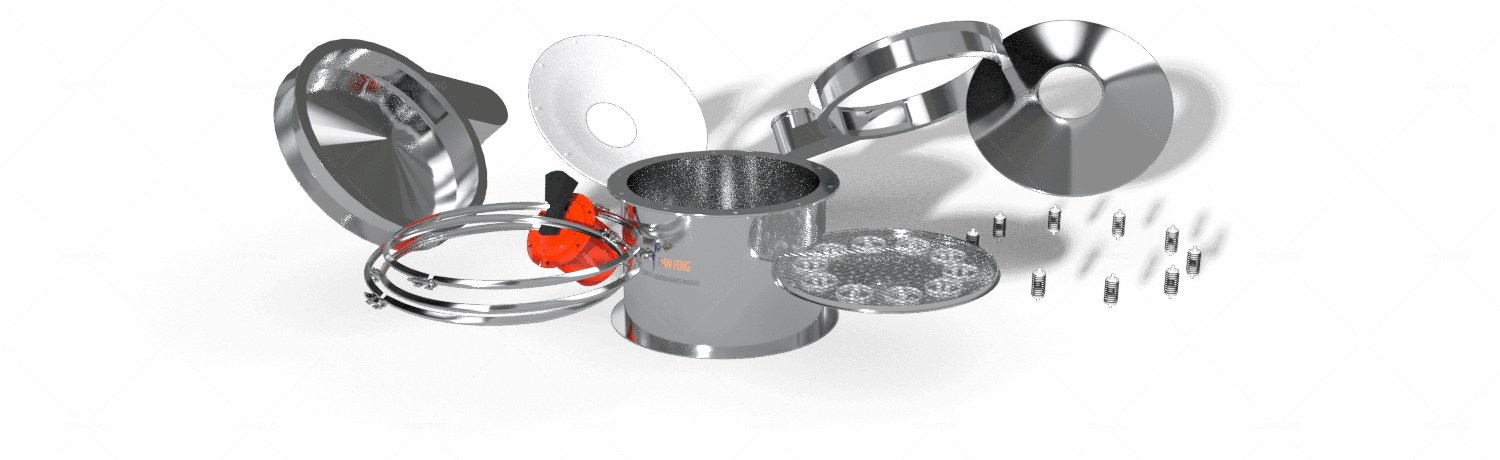

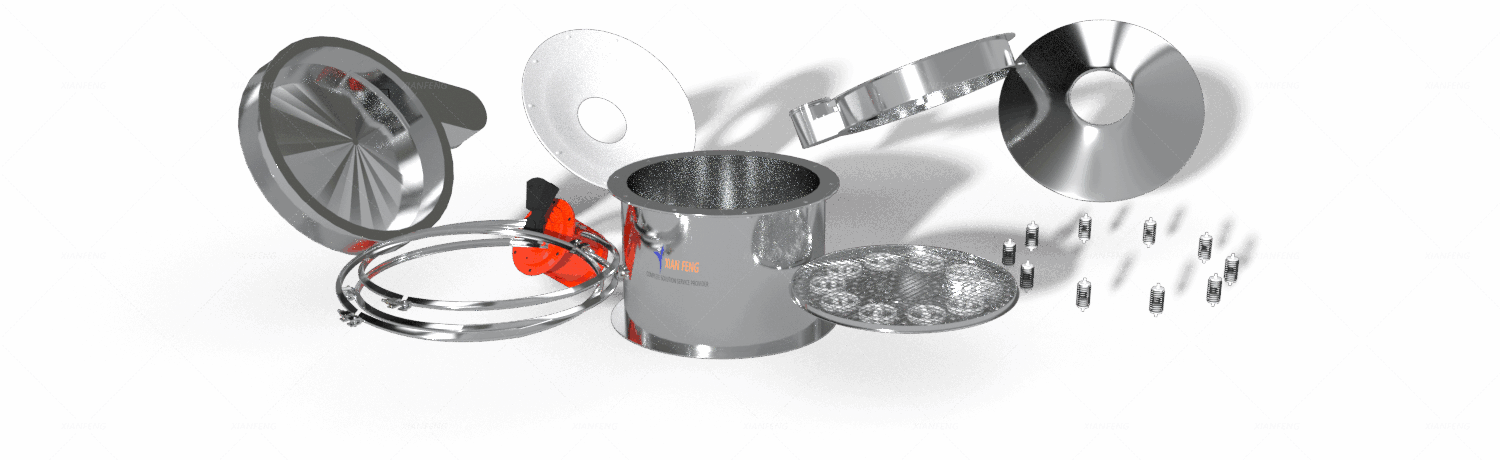

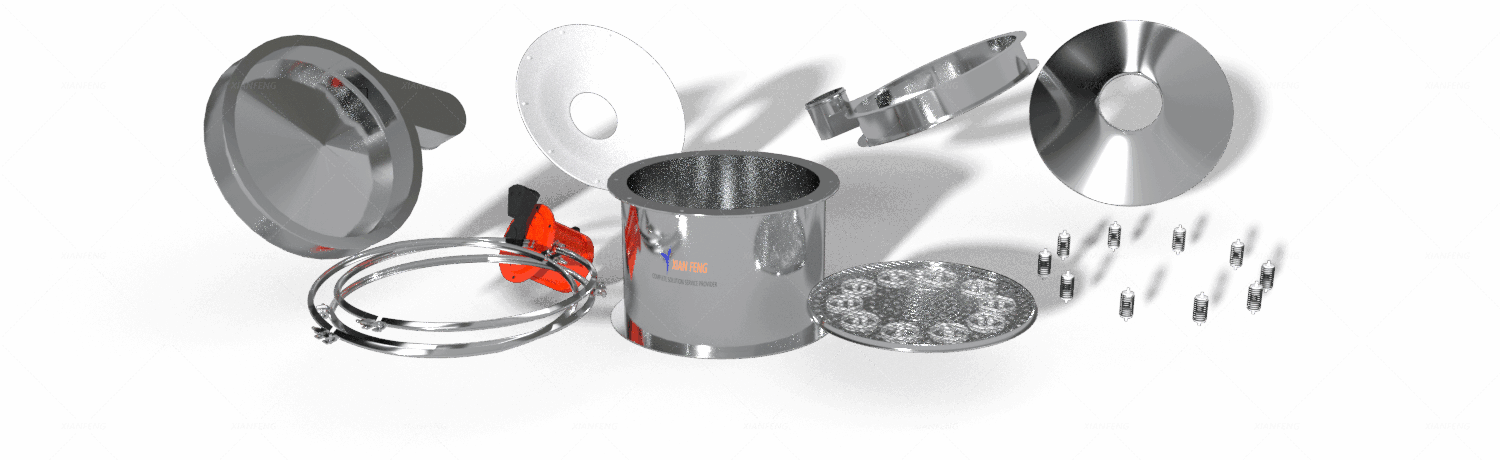

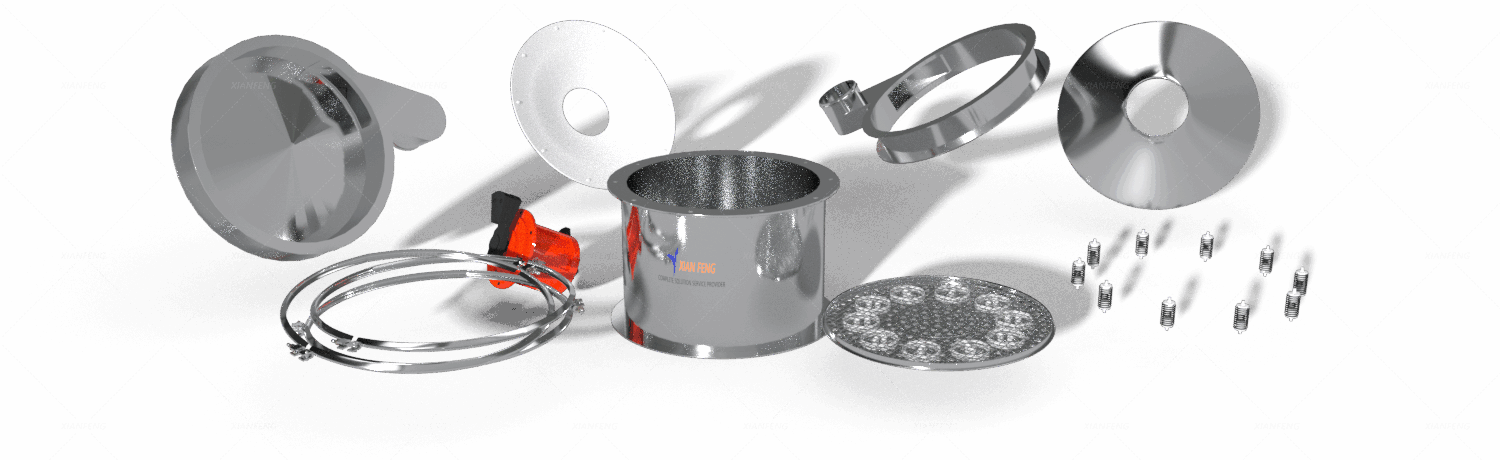

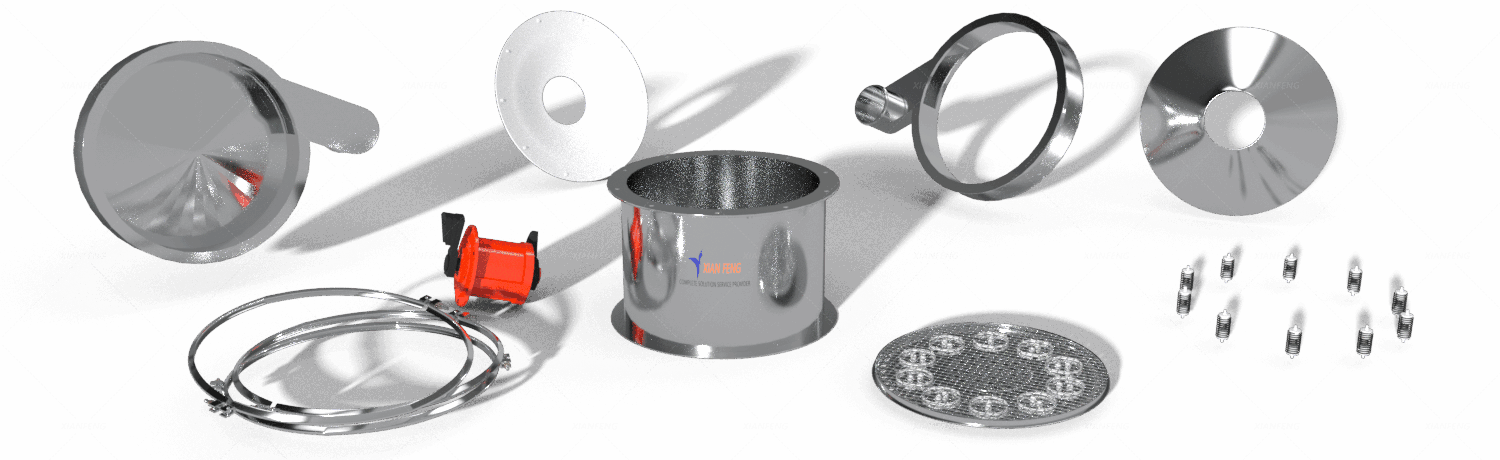

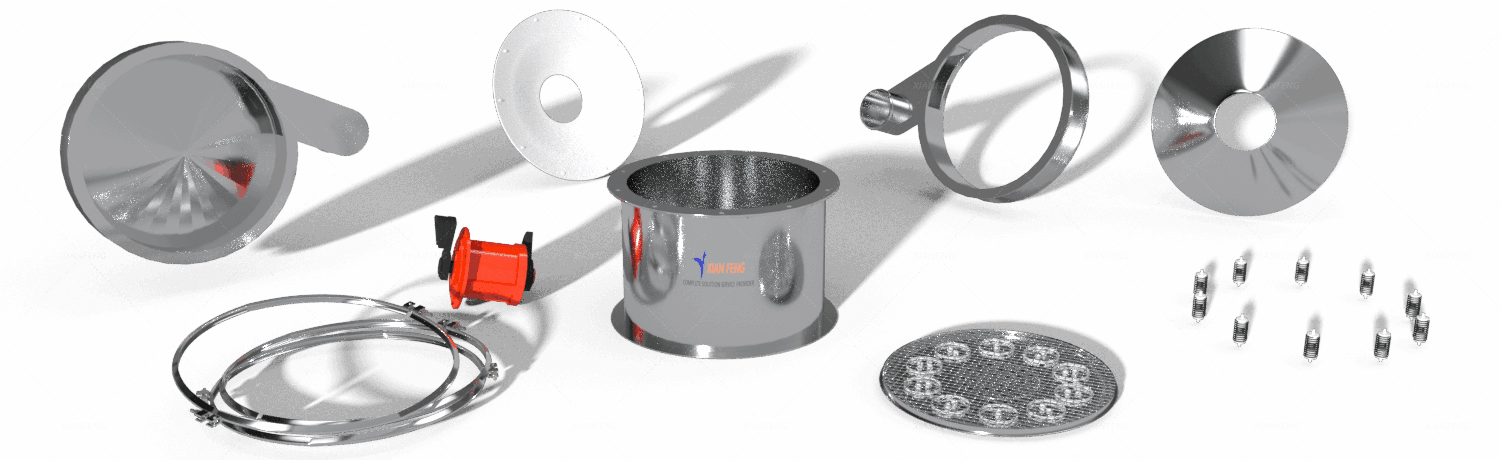

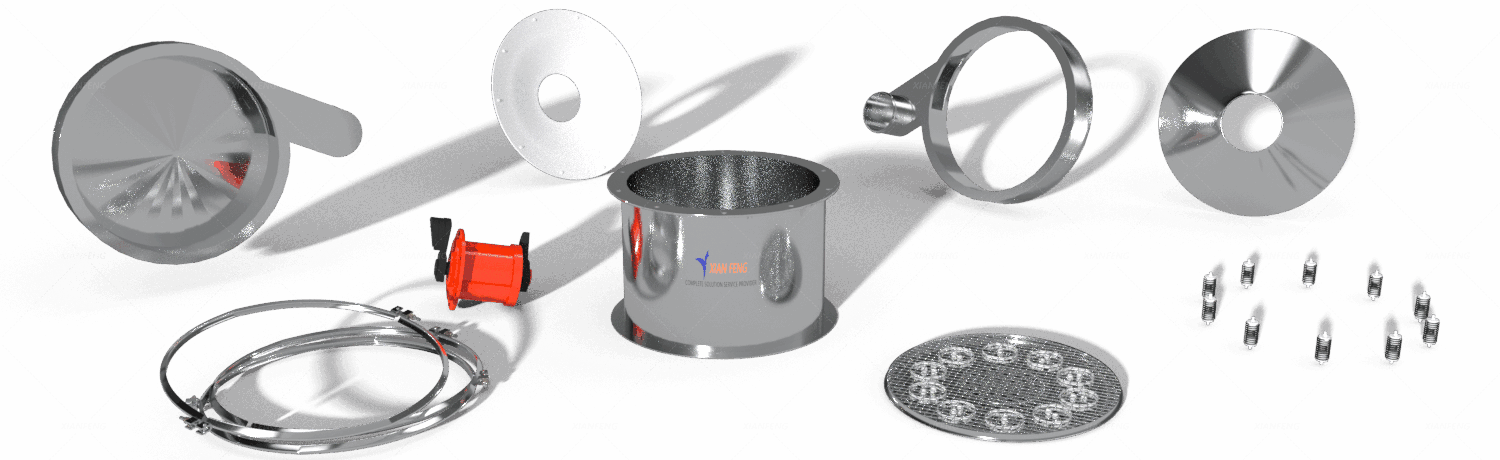

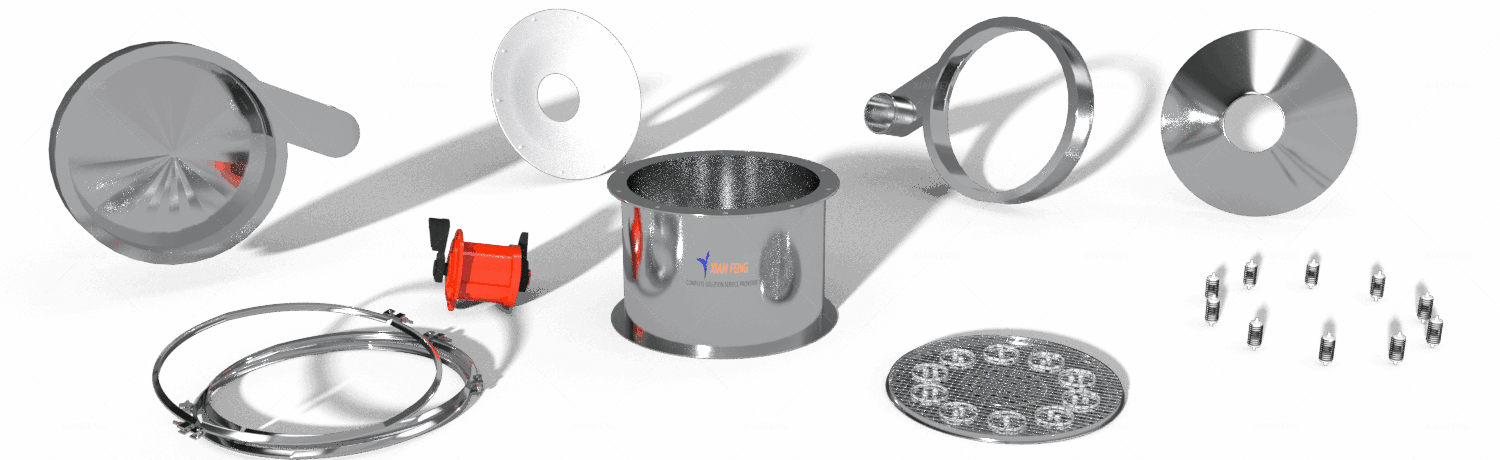

Dust cover

Sieve Frame

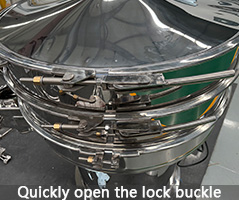

Clamp Ring

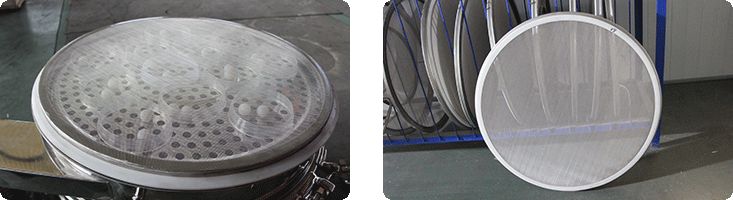

Screen Mesh

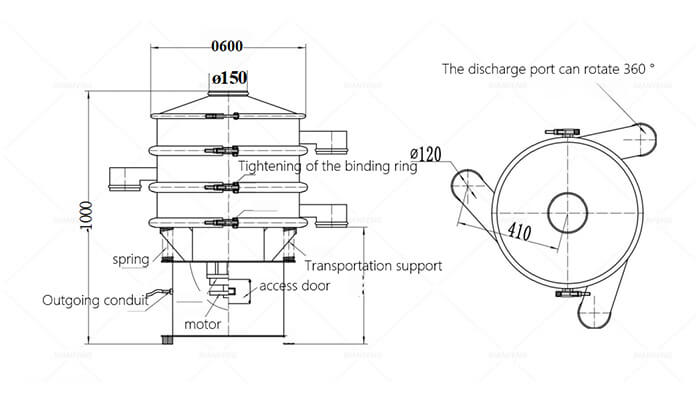

Motor and Spring

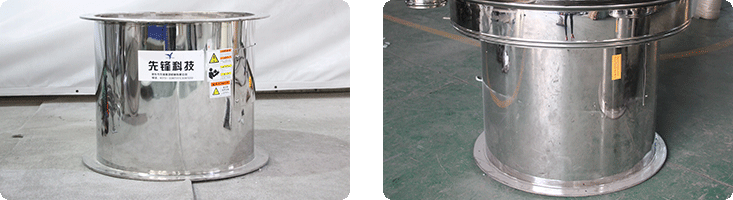

Base

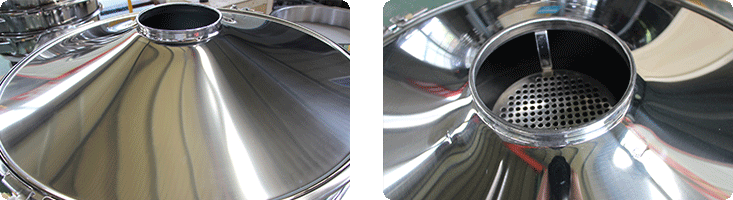

The circular vibrating screen has undergone fine polishing treatment

The feeding port can be customized

Strict sealing eliminates the risk of material leakage

The screen frame can be stacked up to 6 layers with screen meshes for multi-stage screening

360° horizontal rotation allows for arbitrary change of the discharge port direction

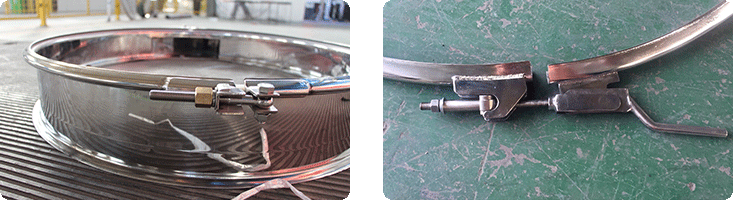

Polished smooth and free of burrs

Strict sealing eliminates the risk of material leakage

Bolt fasteners are precisely tightened without loosening

Customized quick-opening structure for easy and rapid replacement of screen mesh

Strict sealing eliminates the risk of material leakage

Customizable screen mesh ranging from 2-500 mesh, suitable for different screening needs

Select high-elasticity elastic balls for net cleaning, with two materials available: rubber and silicone.

For ultra-fine powder, an ultrasonic system can be customized

Imported Ouli Wolong motor, with strong power, can operate stably under various harsh working conditions

Cold-rolled forming, high-temperature tempered spring, high strength, durable

The base, with its integrated upper and lower flanging, boasts high strength

Customized fully enclosed bottom bucket to cope with acid and alkaline working environments

Provide a wide range of materials, surface treatments, and paint options to meet customer needs.

The circular vibrating screen adopts a dedicated vertical motor with eccentric blocks on both the top and bottom, and can freely adjust the angle to change the magnitude of the vibration force. It is also known as a three-dimensional vibrating screen because it can provide vibration force in three directions: horizontal, vertical, and inclined. During screening, the material undergoes jumping and rotating motion on the screen surface, and different specifications of materials are classified according to the mesh size. It is a universal vibrating screen that can be used in various industries, Stainless steel vibrating screen are particularly widely used in the food and pharmaceutical industries.Due to its small footprint, simple and durable structure, easy replacement of screen mesh, and compatibility with various voltage specifications, it has received high praise from customers.

dust cover, screen frame, screen mesh, cleaning elastic ball, punching tray, tie ring, spring, vertical motor, and base.

Its main function is to prevent internal materials or dust from overflowing during feeding. It can be customized according to the actual situation to adapt to different feeding equipment.

Shaped by a high-precision coiling machine and welded with fish scale patterns to ensure strength, it ensures no looseness, deformation, or cracking under high-frequency vibration, and efficient transmission vibration ensures screening efficiency.

Made of 304/316 stainless steel, with precise mesh holes.

Made of rubber/silicone material to meet various material requirements, ensuring elasticity, durability, and preventing damage, powder loss, and material contamination.

made of high-strength steel material, with rounded and polished material that does not adhere during cutting.

V-shaped is used for connecting and interlocking components such as screen frames, with high quality and no vibration cracking. Bolts or quick opening structures are optional.

High load-bearing, high elasticity spring, efficient shock absorption and wear resistance.

Imported Ouli Wolong motor is used, with high amplitude and low power, which is more energy-efficient. Explosion proof motor can be selected to meet special needs.

The unique high-strength steel cone design evenly distributes the vibration force to the screen frame and screen surface, reducing energy loss and improving screening efficiency.

Rigid support to resist resonance, built-in optimized shock absorption structure to reduce ground impact and ensure equipment safety.

Circular Vibrating Screen | Flour Screening

Rotary Vibrating Screen | Particle Screening

Foreign Material Elimination by Circular Vibrating Screen

Stainless steel vibrating screen

| Model | XF-400 | XF-600 | XF-800 | XF-1000 | XF-1200 | XF-1500 |

| Screen diameter | φ360 | φ560 | φ760 | φ950 | φ1150 | φ1450 |

| Screening area(m2) | 0.1 | 0.25 | 0.45 | 0.71 | 1.05 | 1.6 |

| Screen specification | 2-500mesh | |||||

| Screen layers | 1-3 | |||||

| Motor power(kw) | 0.18 | 0.25 | 0.55 | 0.75 | 1.1 | 1.5 |

Our circular vibrating screen is designed to handle various materials, including powders (such as flour, cement, and chemical powders), particles (such as plastic particles and fertilizer particles), and even liquids containing solid particles (such as slurries and coating materials). They perform well on materials with densities and particle sizes ranging from 20 mesh to 500 mesh. Professional models can also handle corrosive materials through customized screen surfaces and frame materials.

Of course. We offer customization for screen diameters (from 400mm to 1800mm) and overall height/width to match your production line layout. Our engineering team will work with you to review your space limitations and provide 3D drawings for confirmation before production. We can also adjust the number of screen layers (1-5 layers) according to your classification needs.

Most customers use our detailed installation guide to install their own machines, which includes step-by-step videos and charts. The machine is pre assembled and only needs to be connected to the power supply and feeding/discharging system. If necessary, we can provide real-time online guidance through video calls.

For standard models, production takes 7-15 days, with sea freight (30-45 days), air freight (7-10 days), or express delivery (3-5 days) depending on your location and emergency situation. We cooperate with major logistics providers (Maersk, DHL, FedEx) to handle customs clearance procedures on your behalf to ensure smooth delivery.

Yes, it is. Our rotary vibrating screen has passed CE and ISO9001 certification. They comply with the EU Machinery Directive (2006/42/EC) and use food safe materials (304 stainless steel) in situations involving contact with consumables. We can provide all necessary certification documents for customs clearance and quality audit.

23 years of experience specializing in screening and conveying equipment manufacturing [Rich experience, providing complete customized solutions]

40,000 square meter factory, a genuine source manufacturer [No middlemen, lower prices]

50 technical patents, CE/ISO certifications [Technology proven, trustworthy]

20 years of export experience, equipment exported to over 70 countries worldwide [Full-process support from a professional team]

Ensure your product quality and reputation.

Our professional solutions are designed to maximize your production efficiency.

Reduce production downtime, resource waste, and maintenance issues.