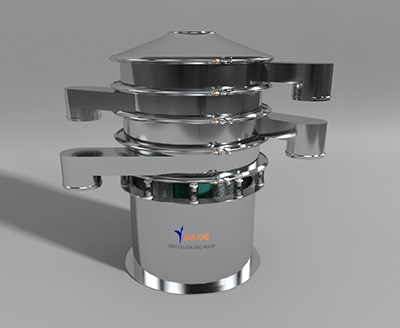

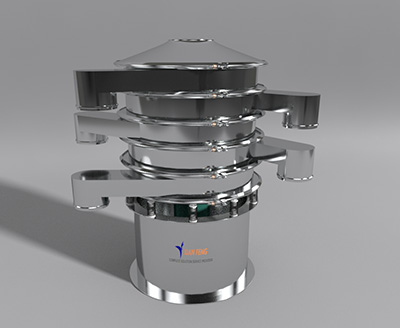

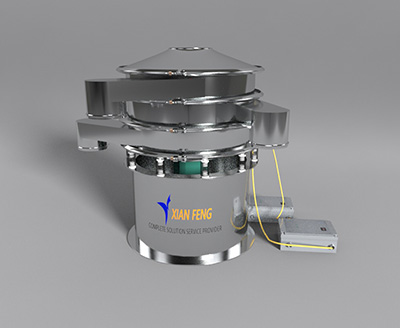

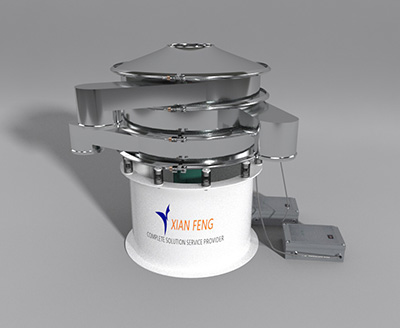

Inert gas vibrating screen & 3D printing recycling vibrating screen, is a screening equipment specially designed for processing materials that are prone to oxidation, flammable, explosive or sensitive to the environment. Through a fully enclosed structure and inert gas replacement technology, it ensures that the material is screened in an oxygen-free environment, while also featuring high efficiency, low noise, explosion-proof and other characteristics. It is widely used in food, medicine, chemical industry, new materials, metal powder,3D print and other industries. XianFeng can provide you with customized oxygen-free screening solutions.

3D printing materials: titanium alloy powder (Ti-6Al-4V), stainless steel powder (316L), aluminum powder (AlSi10Mg), etc.; electronic packaging materials: copper powder (Cu), silver powder (Ag); thermal spraying powder: tungsten carbide (WC), nickel-based alloy powder (NiCrBSi), etc

lithium battery cathode materials: lithium iron phosphate (LFP), ternary materials (NCM811, NCA); anode materials: natural graphite, artificial graphite; recycled materials: "black powder" (containing lithium, cobalt, nickel) after crushing decommissioned lithium batteries, etc

zinc oxide (ZnO), titanium dioxide (TiO₂); ceramic precursor powders: silicon nitride (Si₃N₄), silicon carbide (SiC); precious metal nanomaterials: nanometer silver wires (AgNWs), nanometer platinum particles (Pt NPs), etc

functional food additives: probiotics (such as bifidobacteria), vitamins (such as vitamin C); pharmaceutical intermediates: nitrocellulose (NC), aspirin; medical implant materials: cobalt-chromium alloy (CoCrMo), hydroxyapatite (HA), etc

Precious Metal Catalysts: Platinum on Carbon (Pt/C), Palladium on Alumina (Pd/Al₂O₃); Nanocomposites: Graphene, Carbon Nanotubes (CNT); High-Energy Materials: RDX, HMX, etc

Electronic-grade Silicon Materials: Polycrystalline Silicon (Poly-Si), Monocrystalline Silicon (Cz-Si); Photovoltaic Materials: Silver Paste (Ag Paste), Aluminum Paste (Al Paste); Display Materials: Quantum Dots (QDs), Organic Light-Emitting Materials (OLED), etc

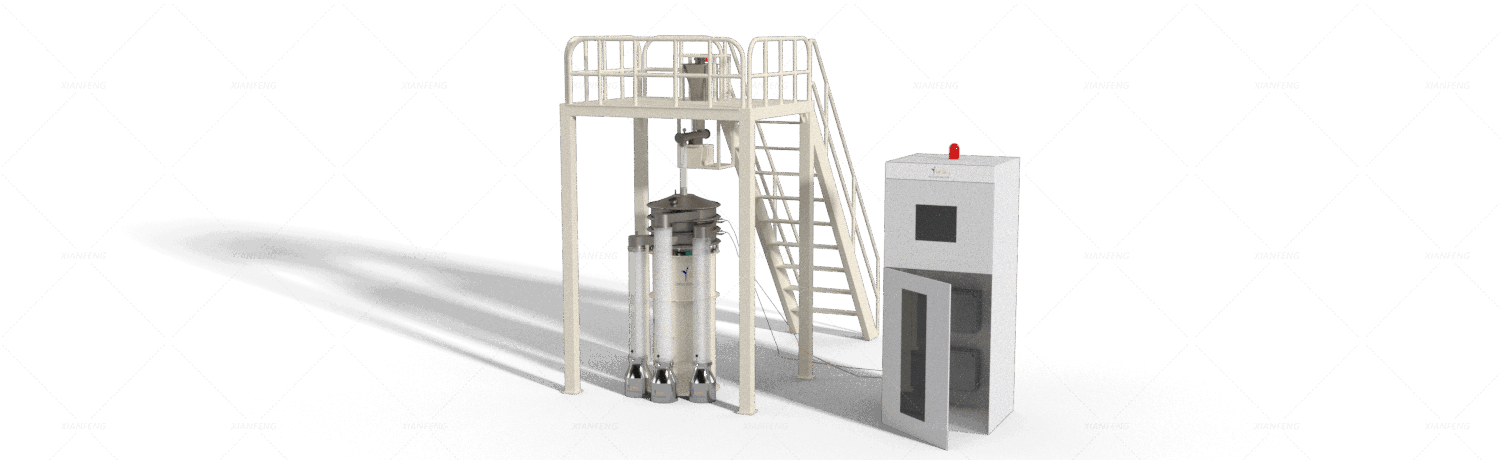

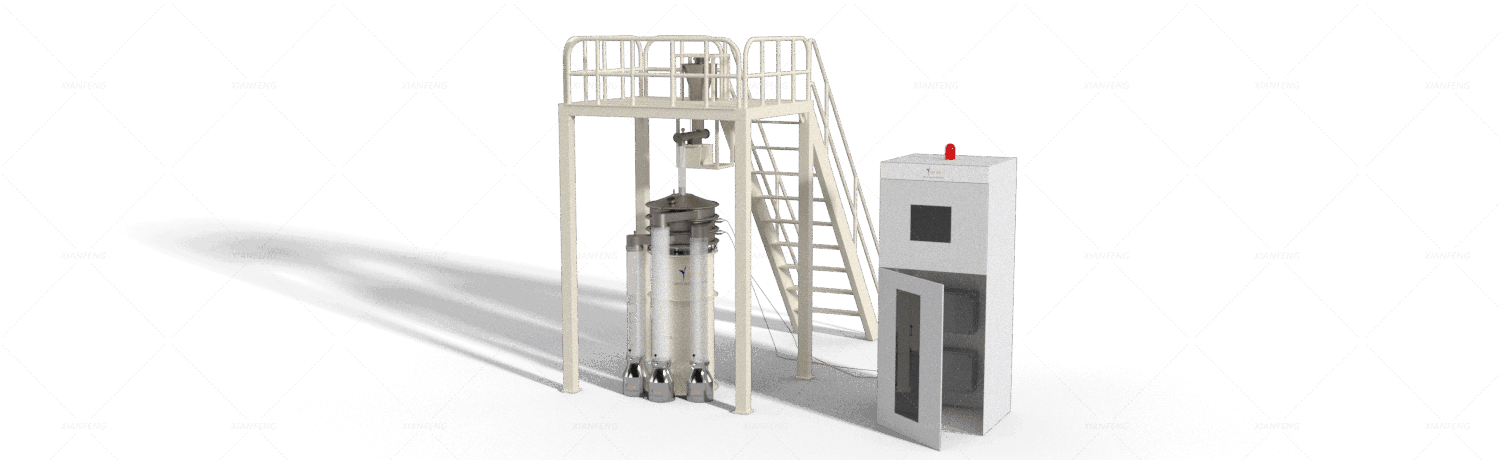

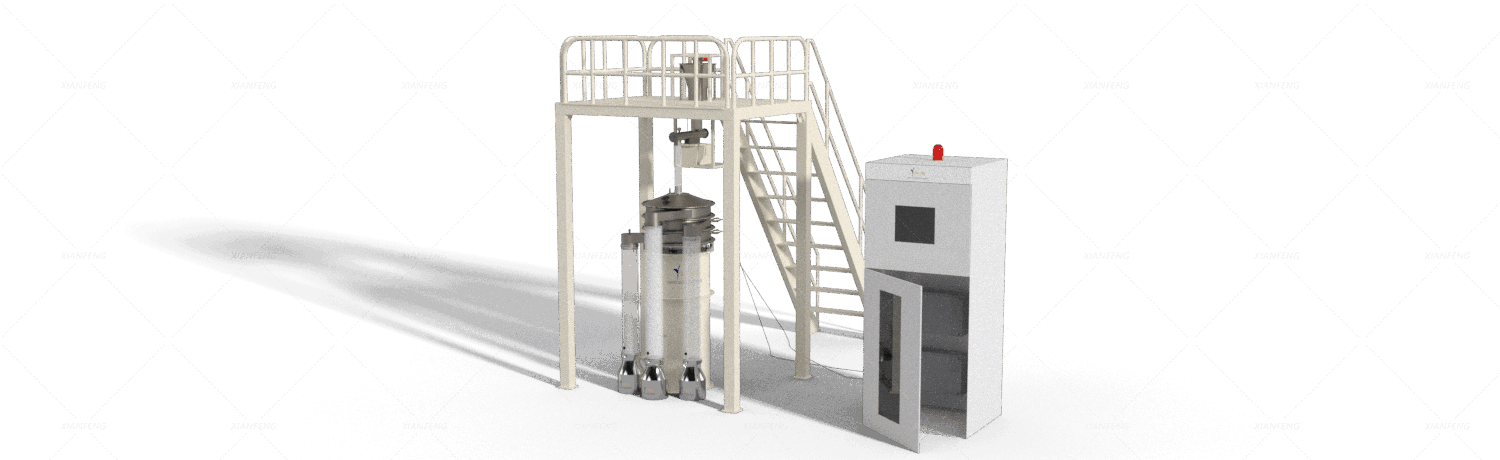

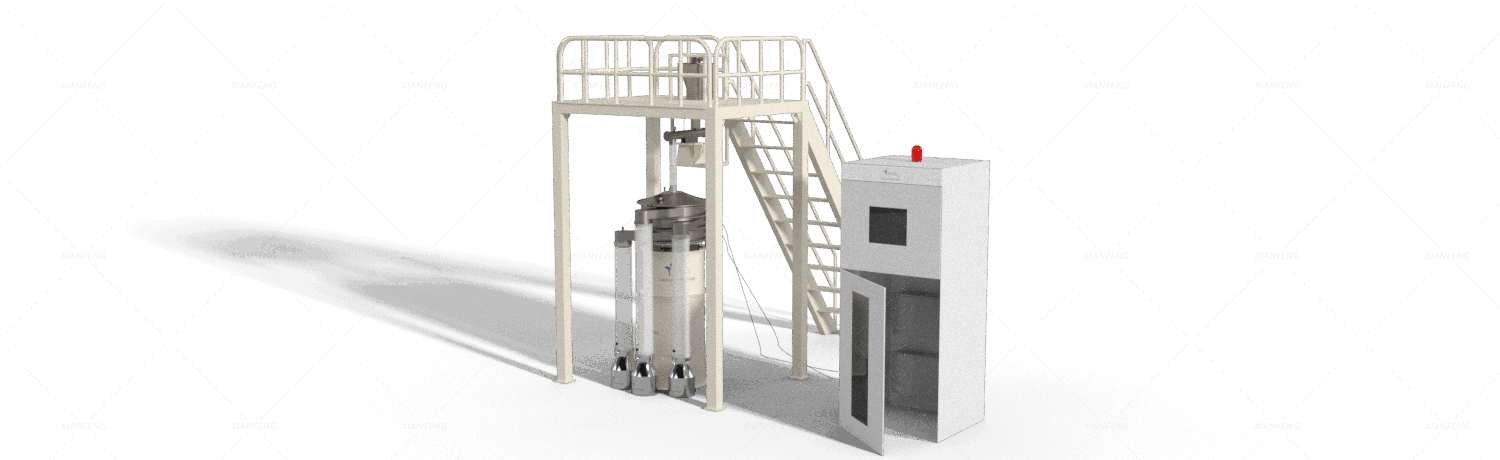

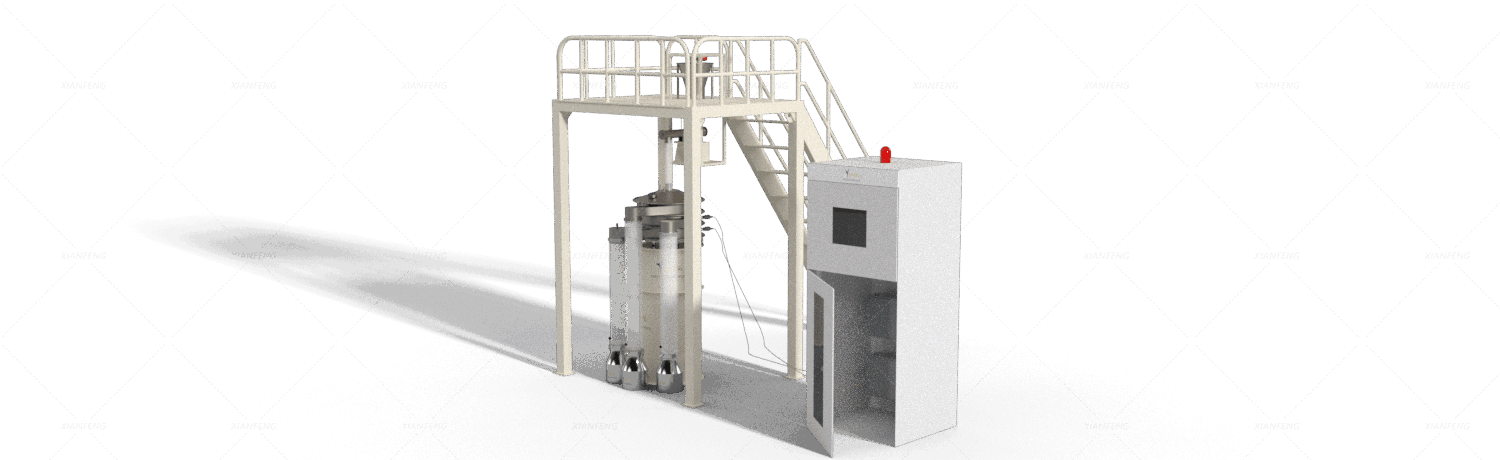

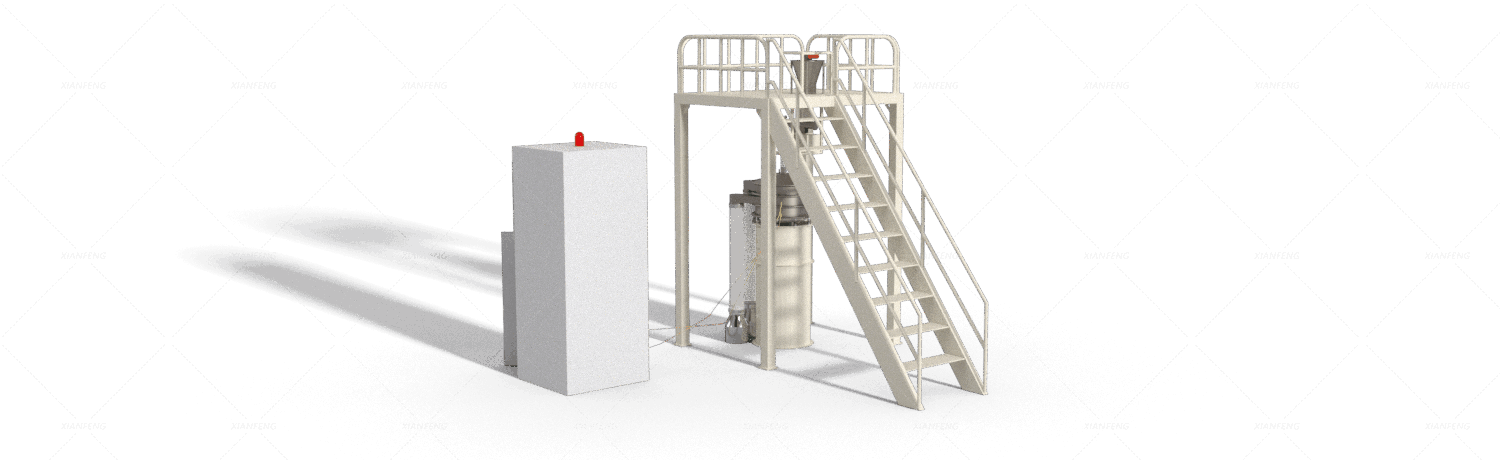

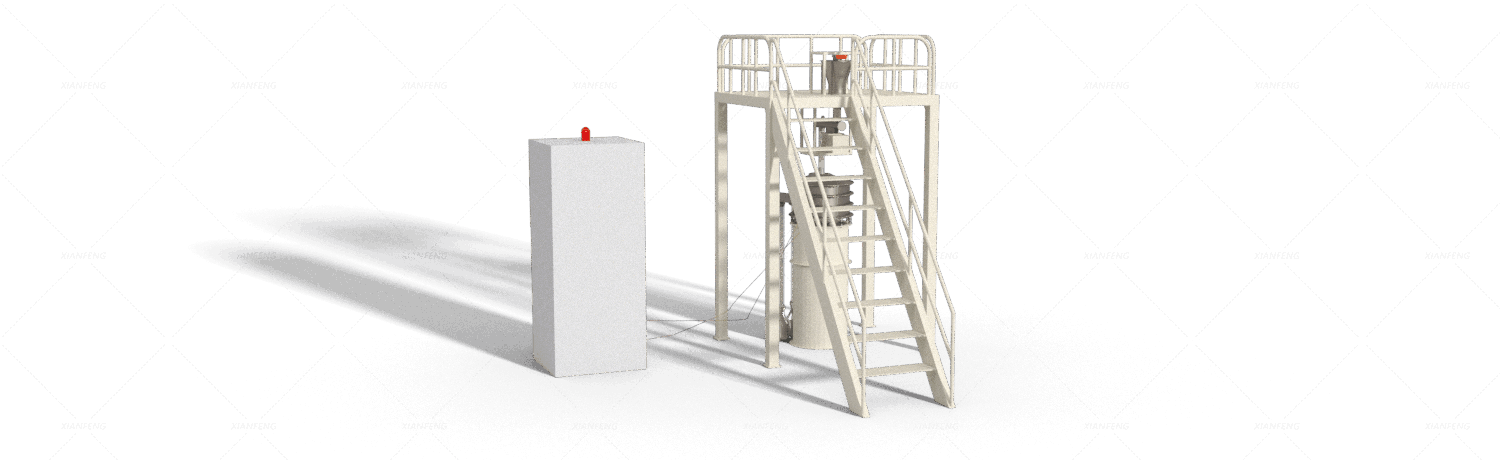

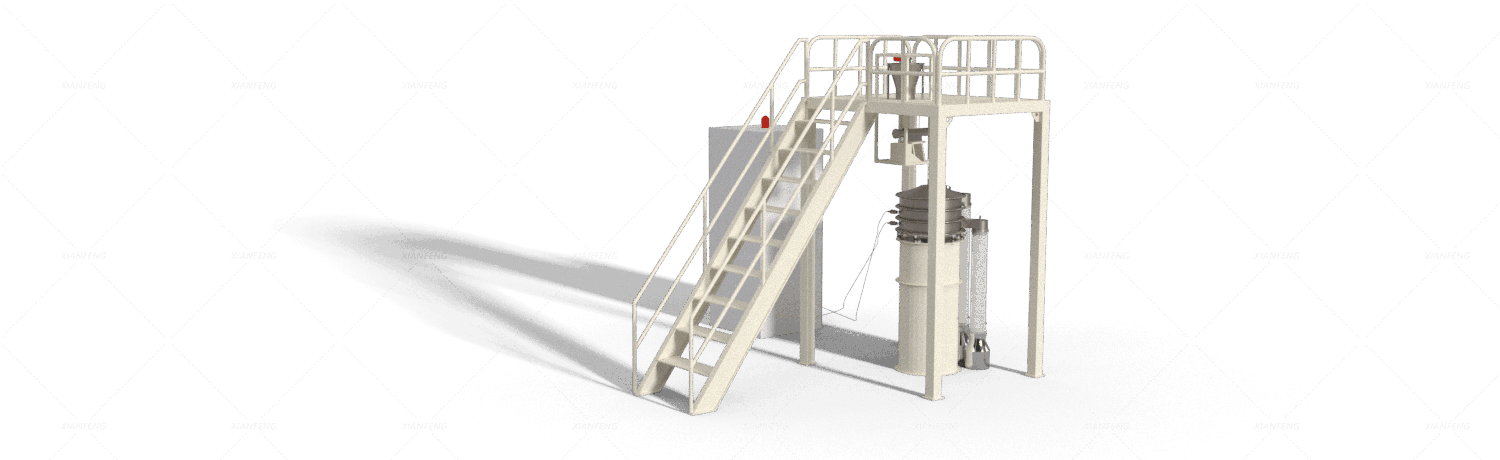

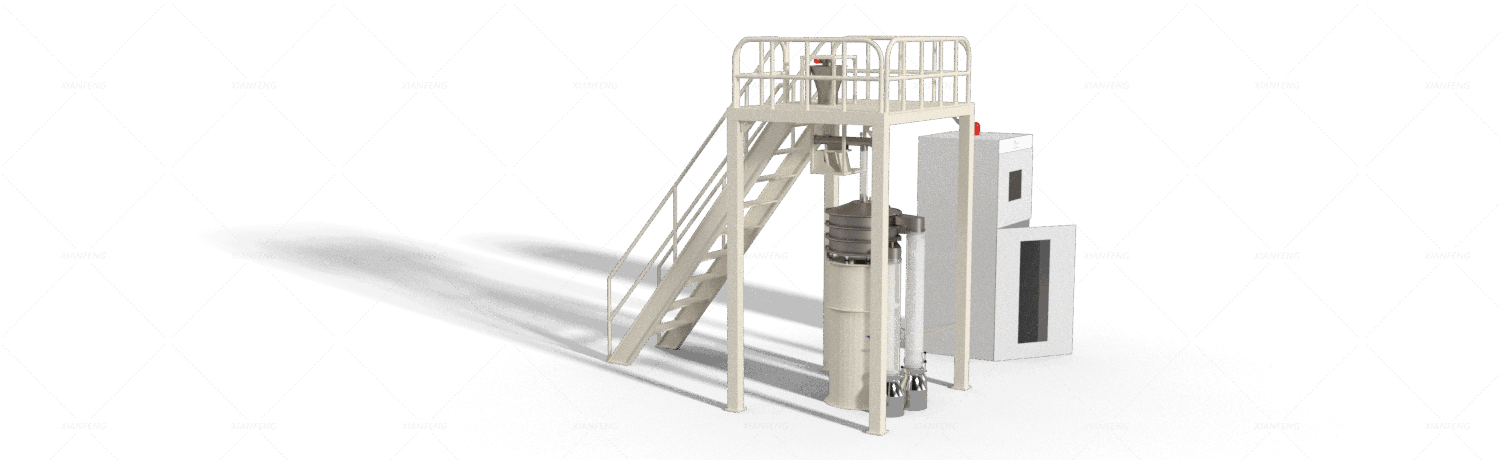

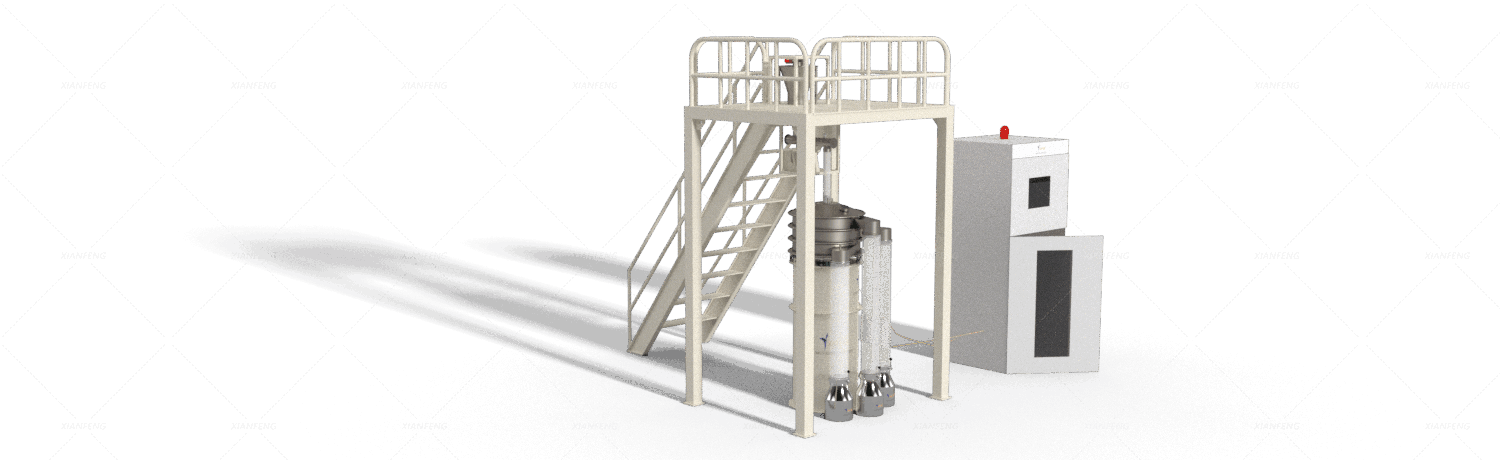

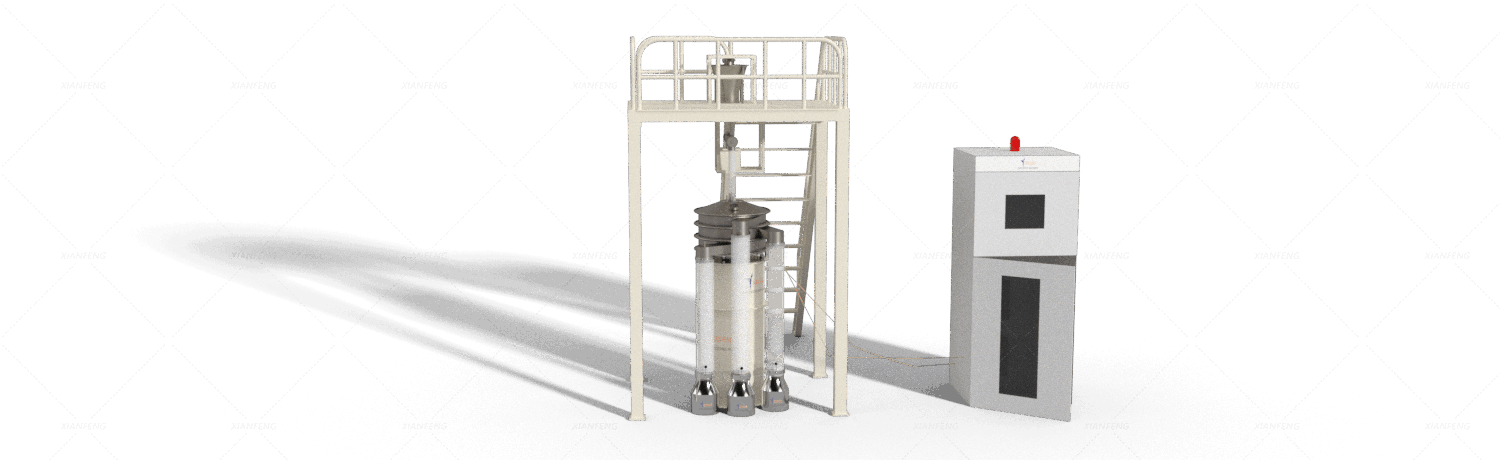

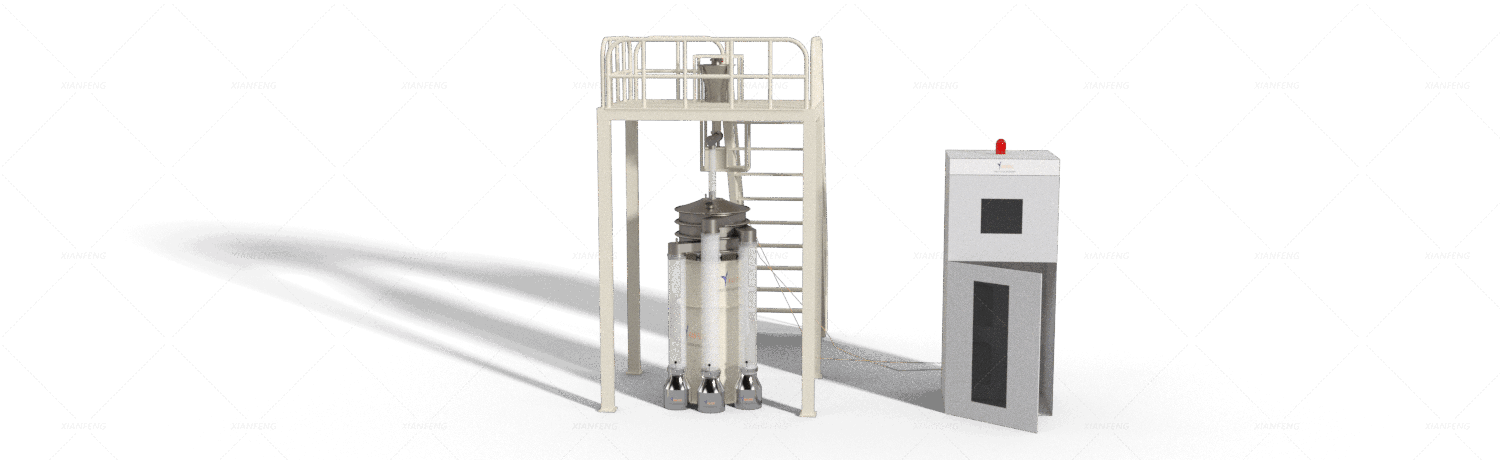

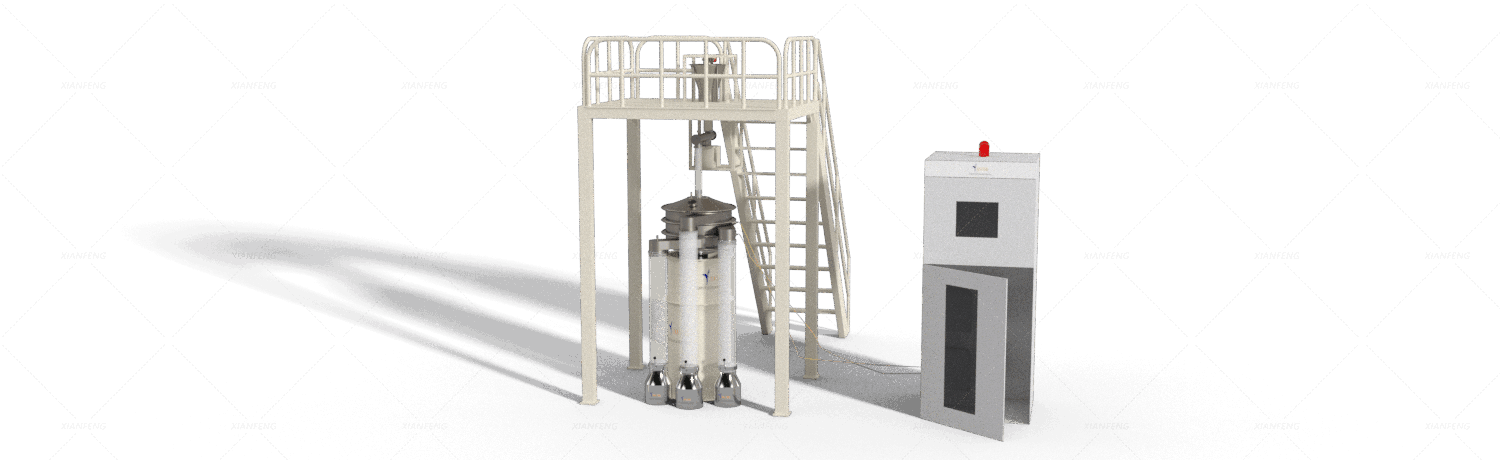

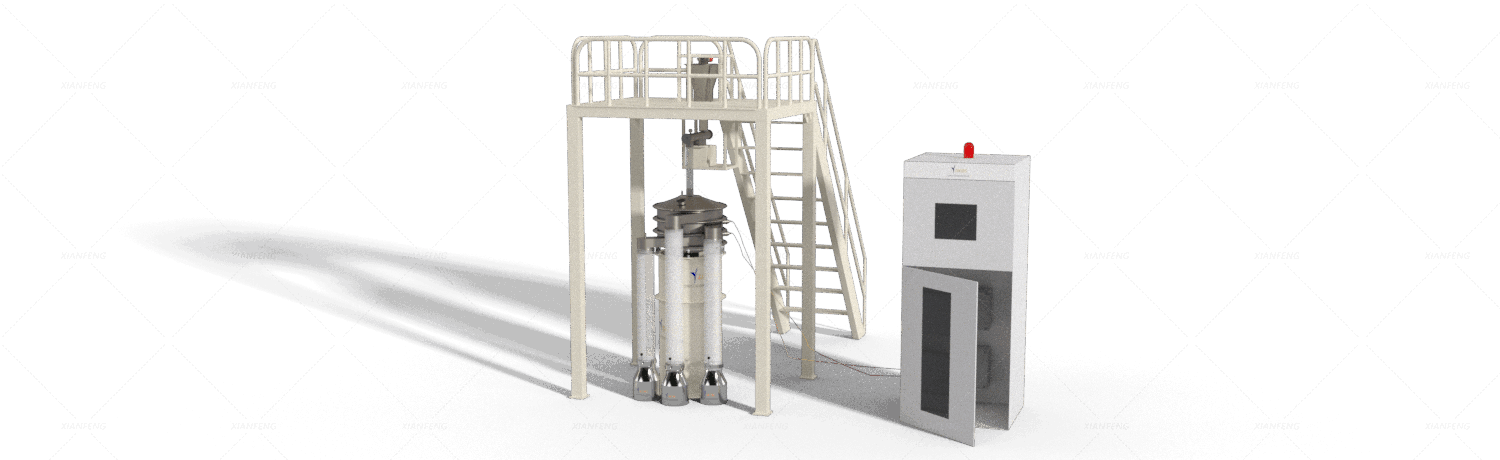

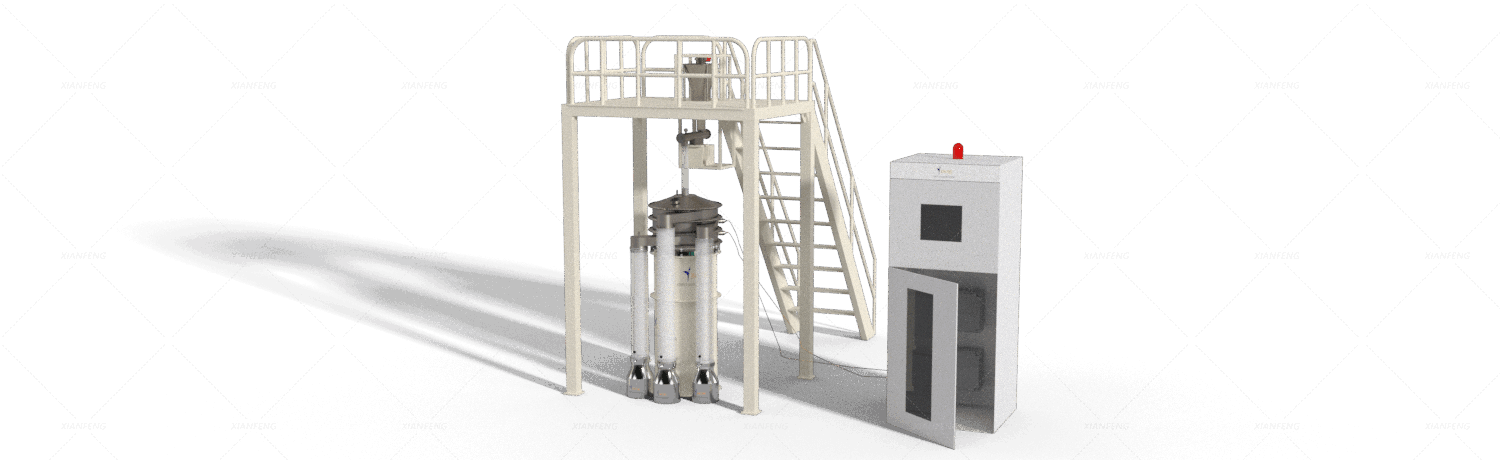

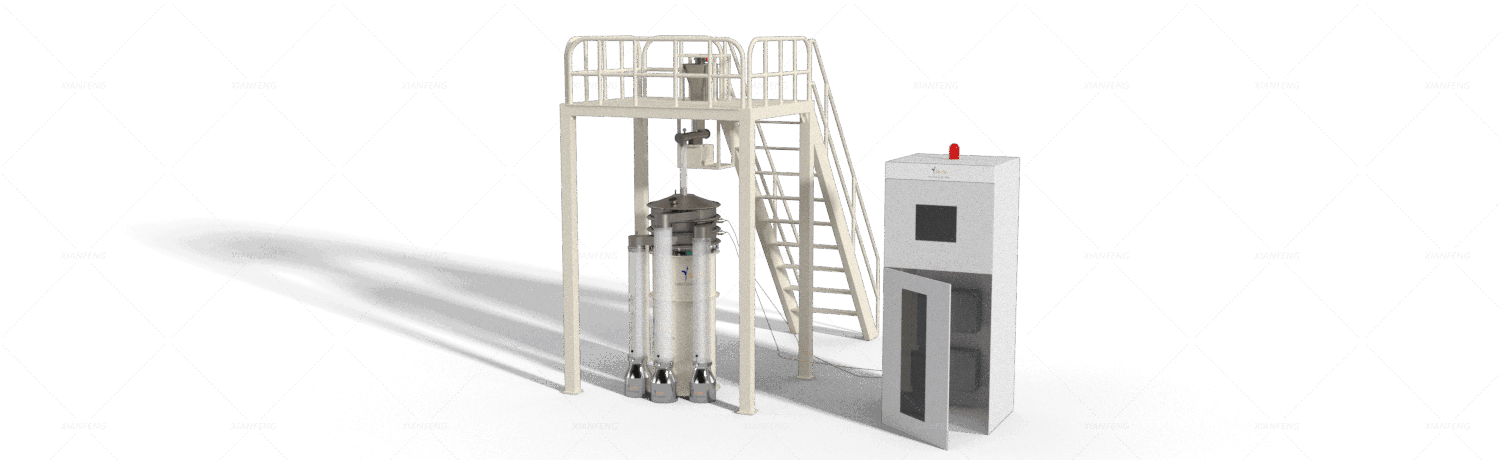

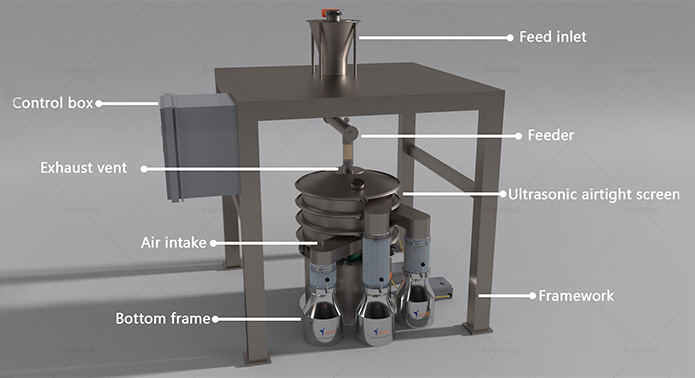

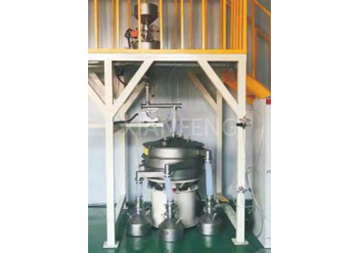

Feed inlet

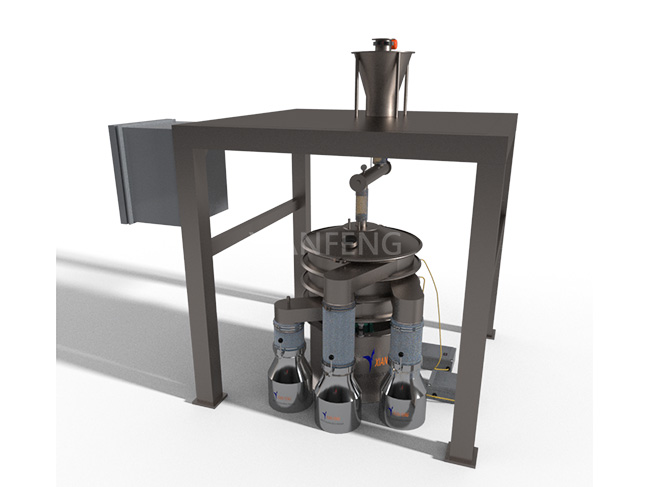

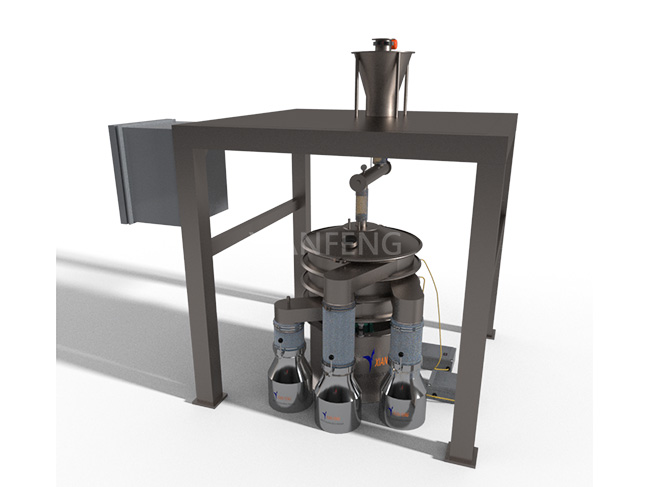

Feeding system

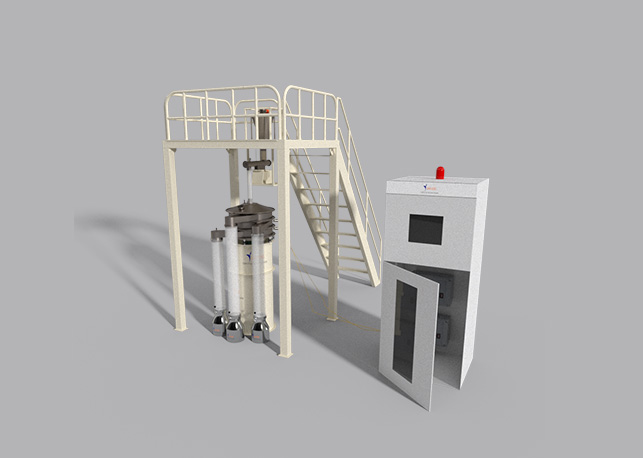

Framework

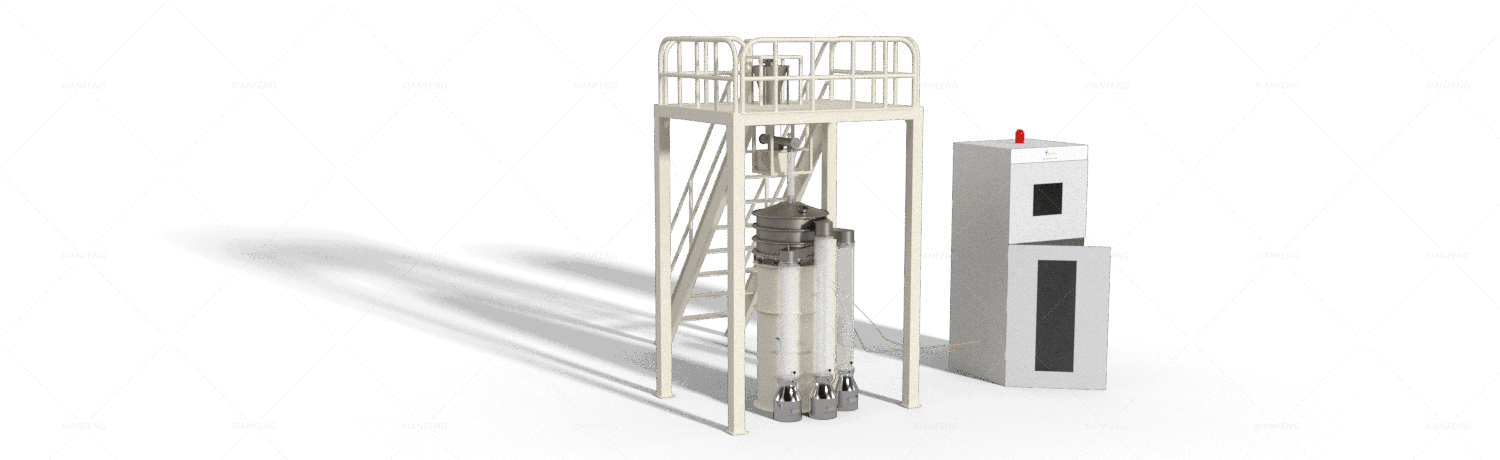

Airtight screening

Storage tank

Intelligent Control Cabinet

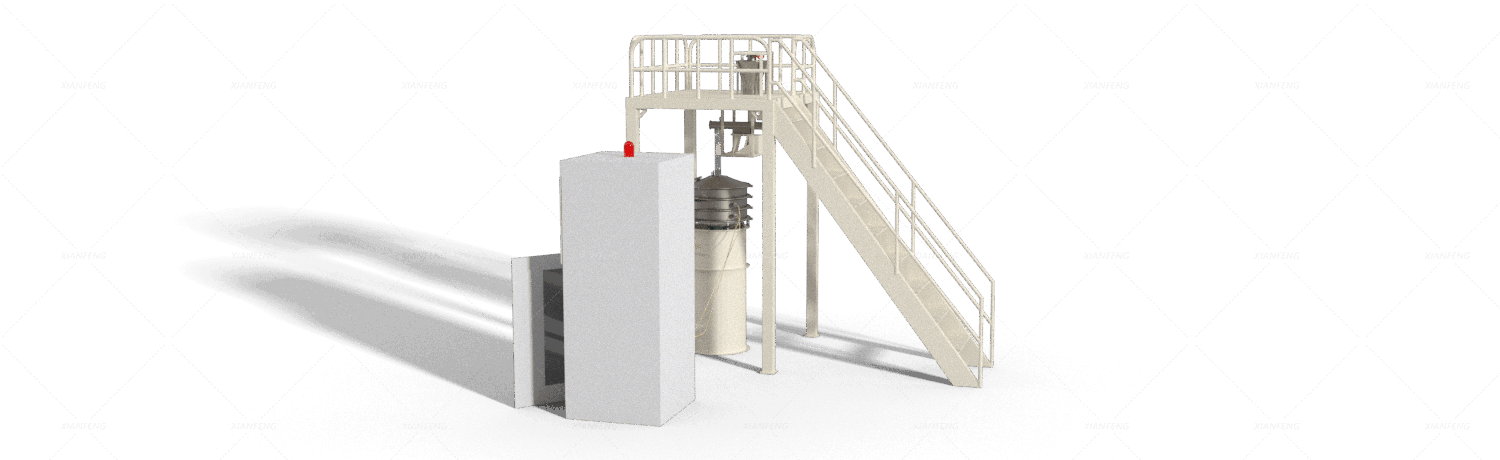

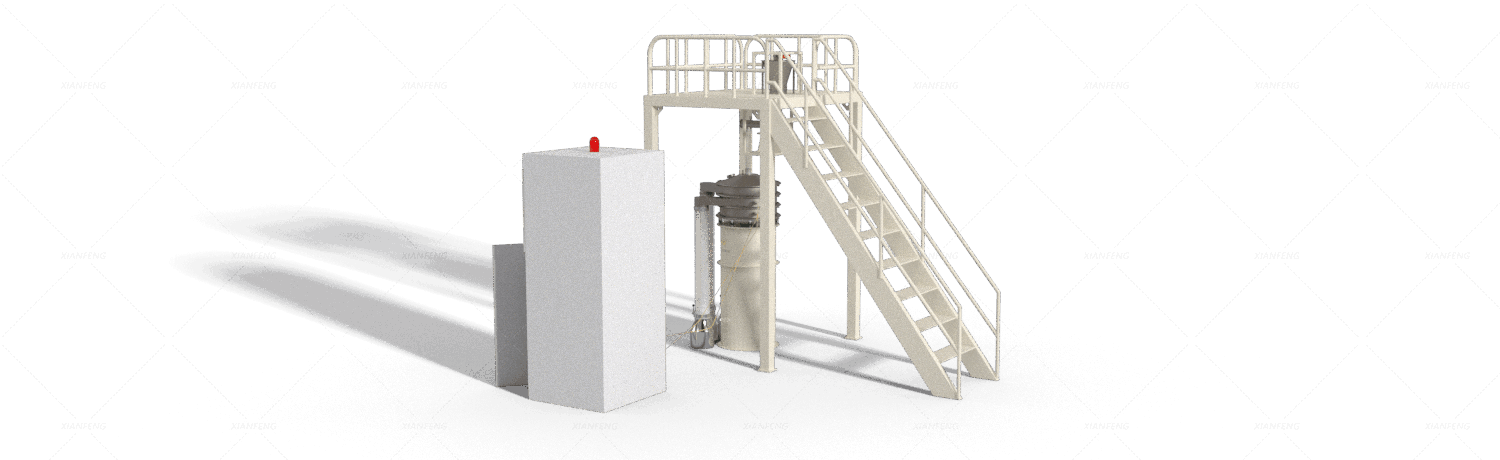

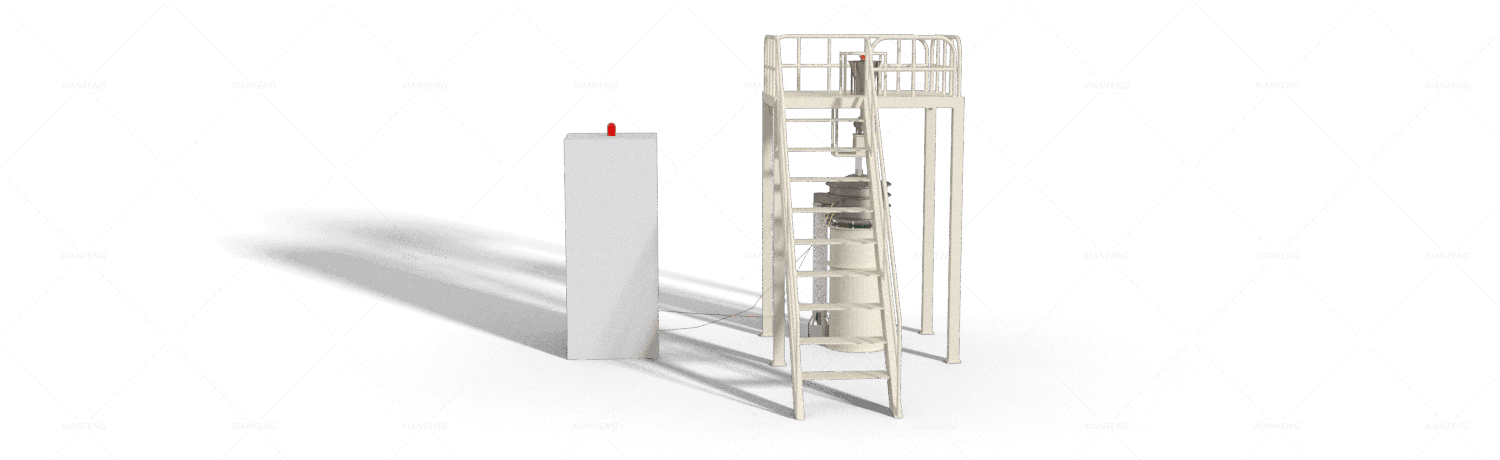

Top feeding, inverted feeding with handheld sealed tank, and customized large buffer material bin unloading according to needs.

The precise sealing link does not leak air.

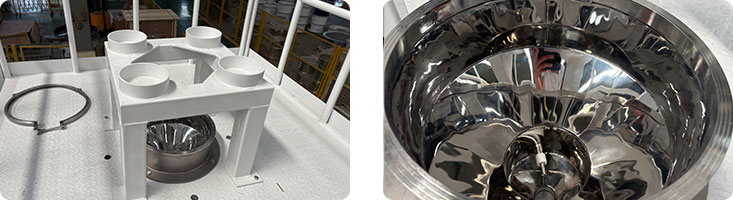

Smooth internal polishing, smooth unloading, and no contamination of high-value materials.

Adopting precise quantitative conveying and unloading, with infinitely adjustable flow rate and uniform particle size distribution.

Prevent material aggregation and effectively screen.

Customize frameworks according to demand to meet various production environments.

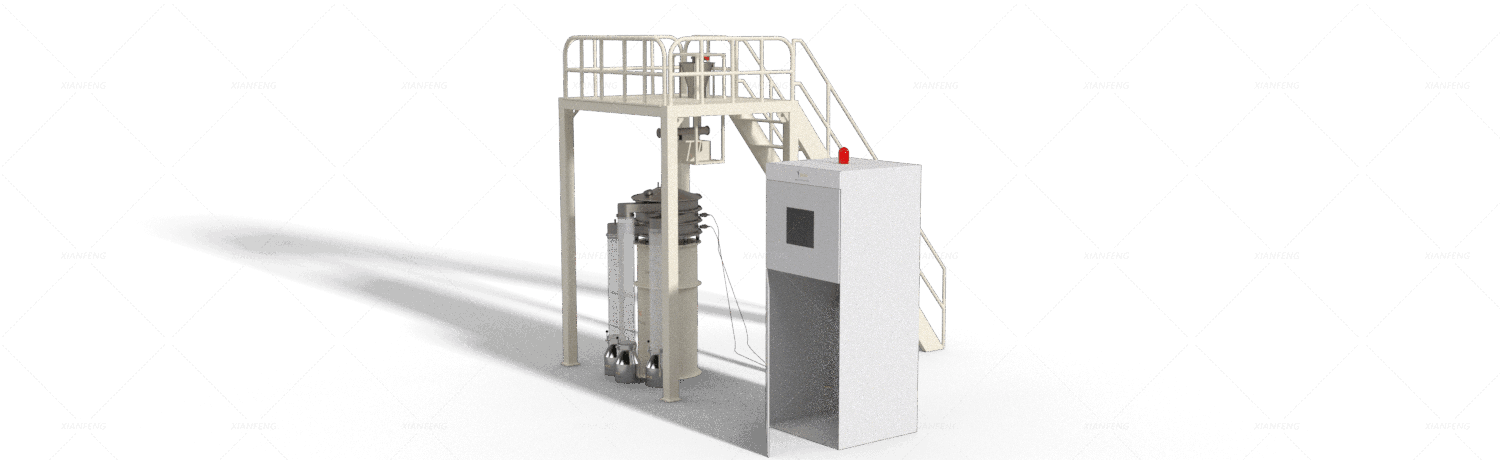

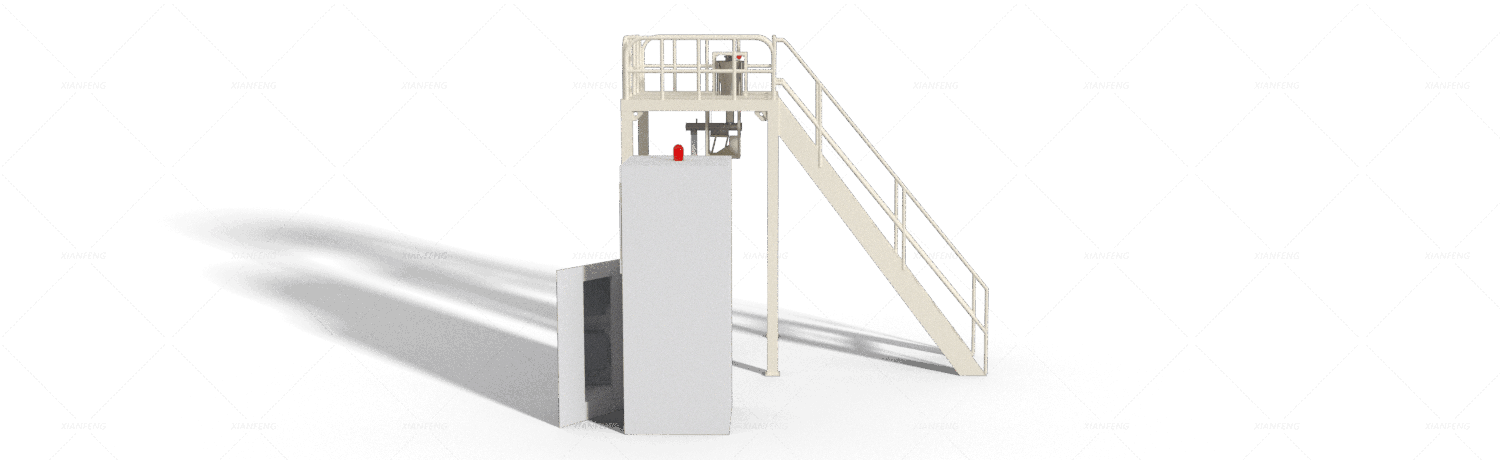

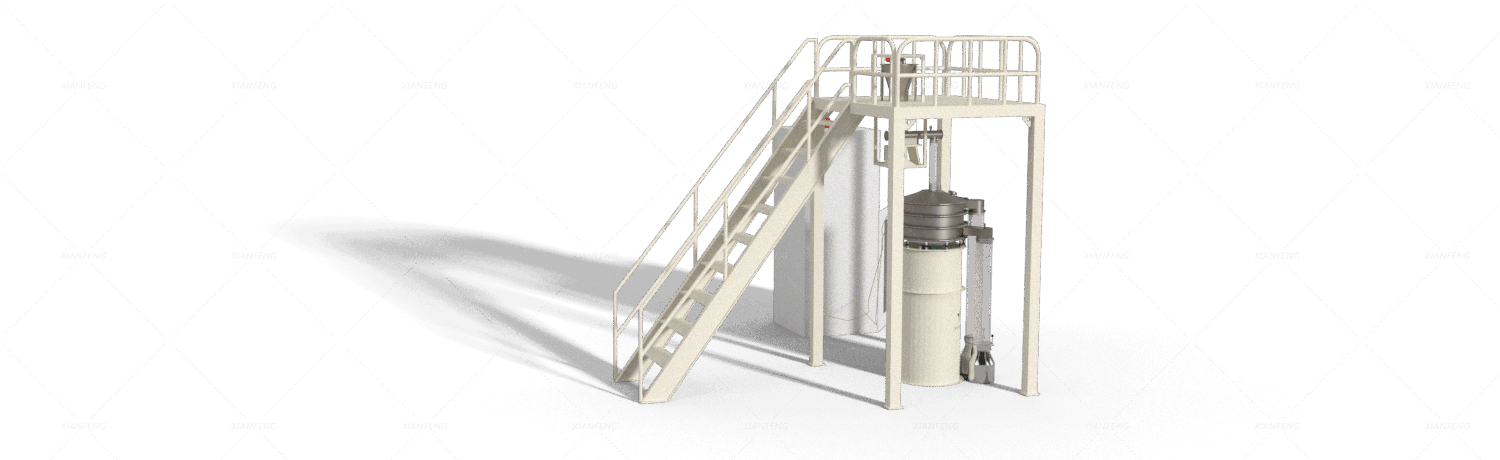

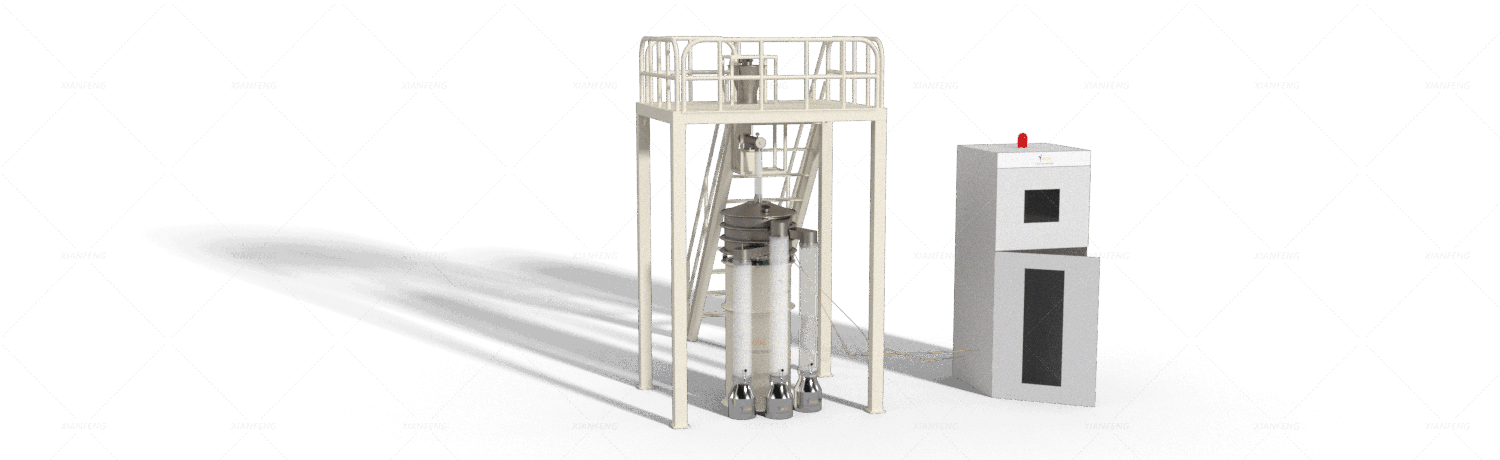

Inert gas protection ultrasonic vibrating screen, customized feeding port and storage tank sealed connection.

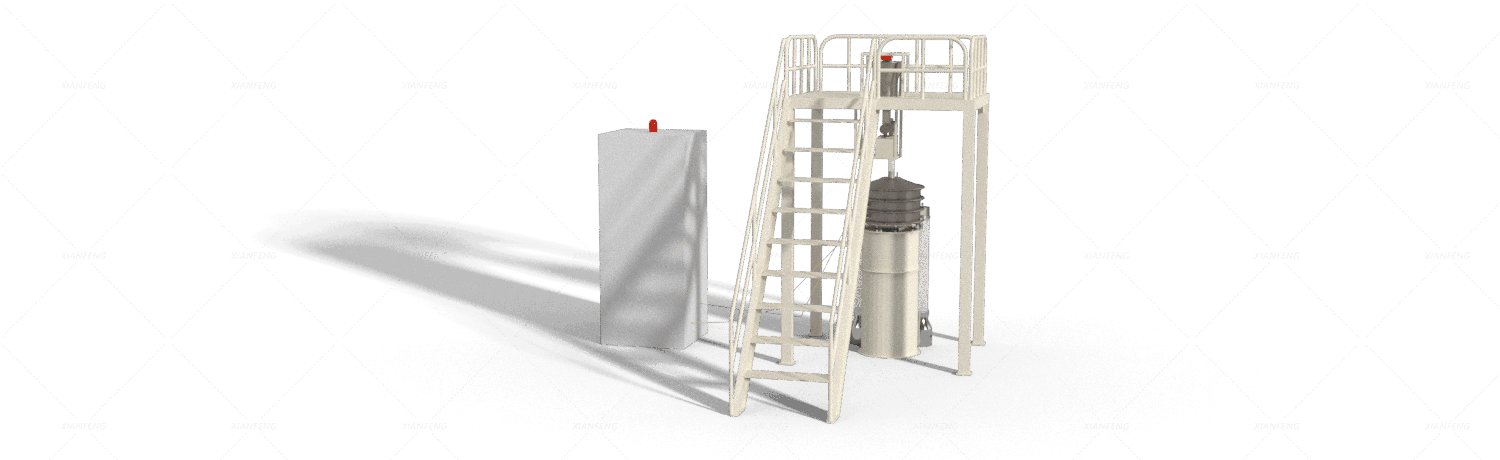

The inlet of the discharge port is equipped with a pressure relief valve at the top, and the connection port can be directly connected to the silo. It is also equipped with an observation mirror to monitor the screening process at any time.

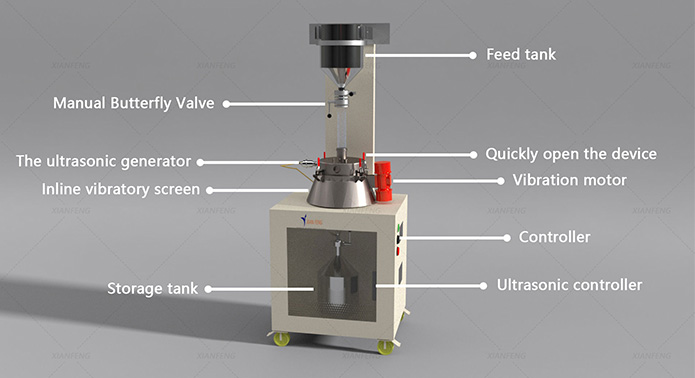

Adopting imported Swiss Olivolon motors, explosion-proof function can be customized according to needs.

Using silicone tubing with clamp connections.

The interface of the storage tank is matched with a manual butterfly valve, which has good sealing performance and effectively guarantees the replacement of finished material tanks without loss.

The 3D anaerobic screening system control cabinet integrates convenient and fast functions.

Intelligent real-time monitoring of air replacement to reduce oxygen content, gas replenishment, overpressure, screen breakage, overload alarm and other functions.

Explosion proof design can be customized as needed.

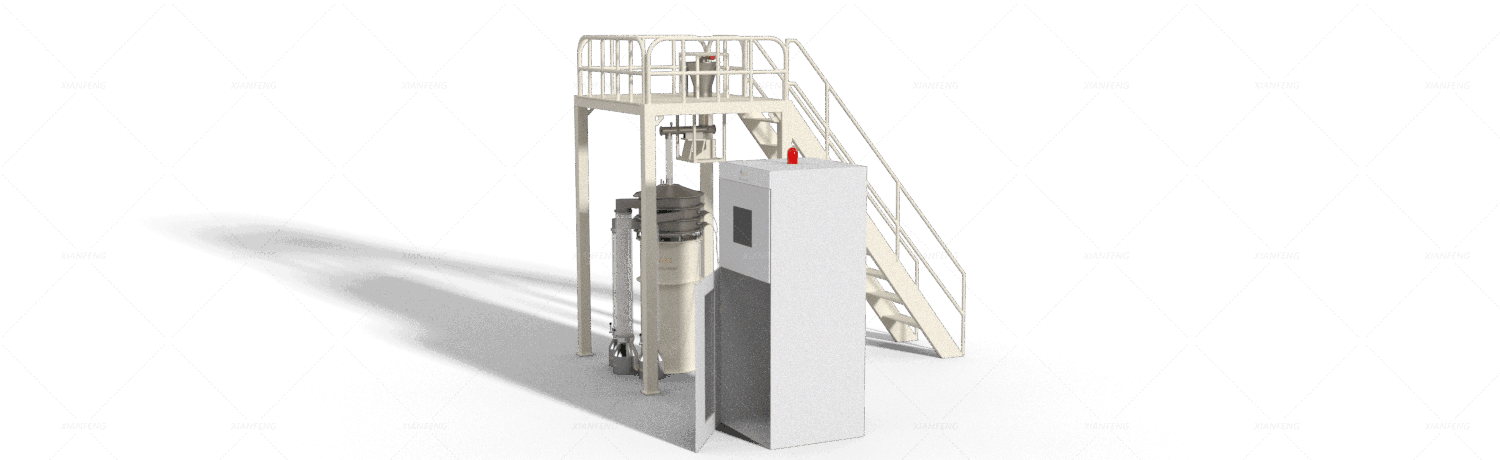

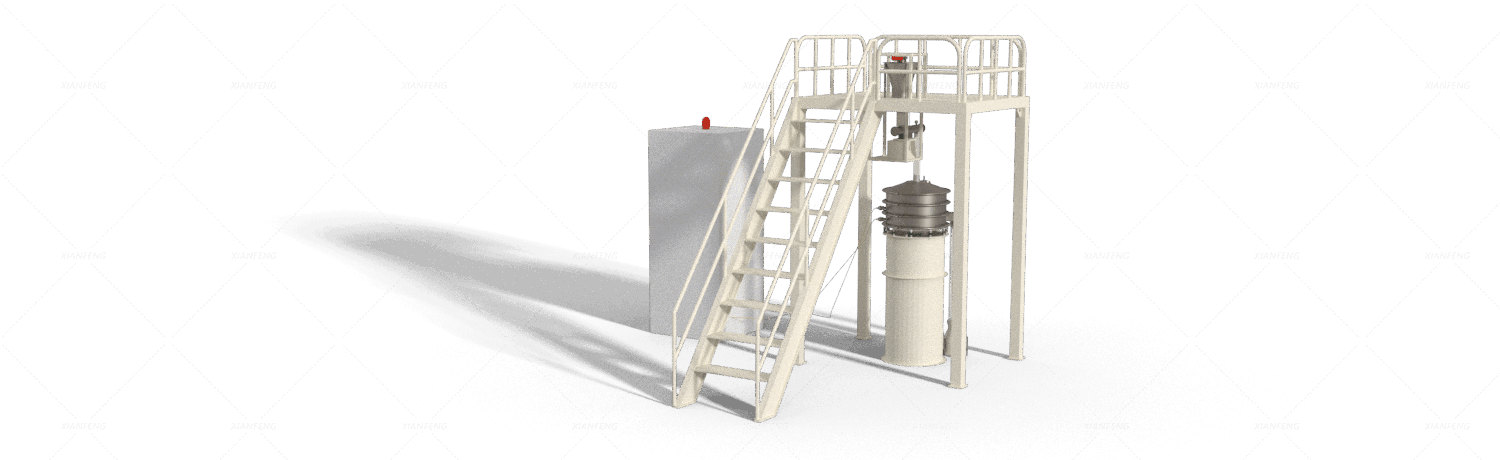

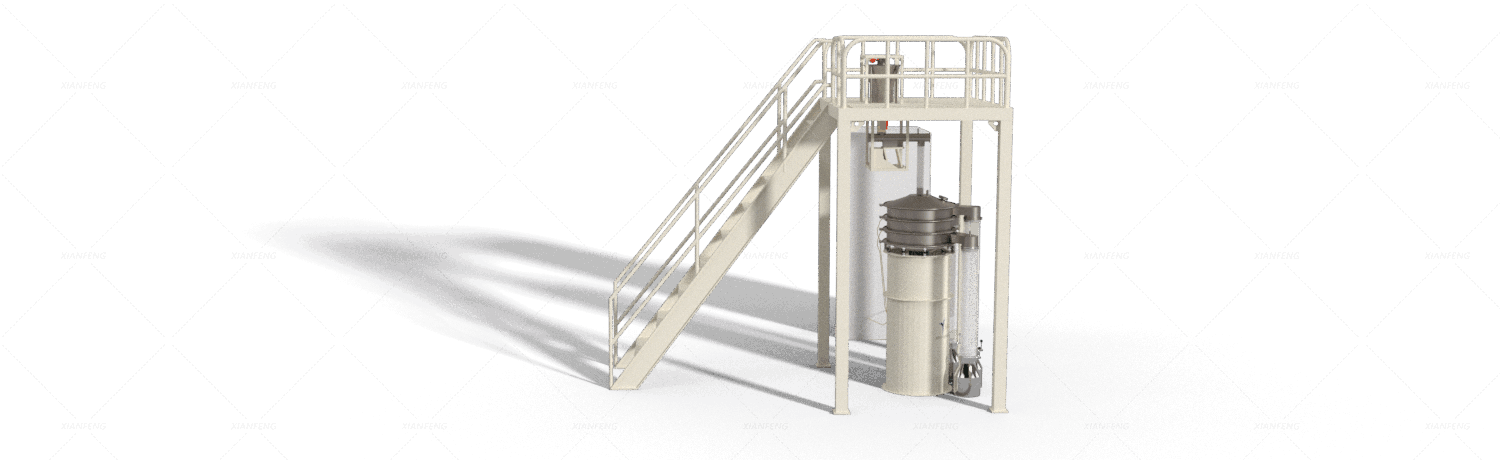

Before starting the equipment, a dedicated inflatable device is used to inject inert gases such as argon (Ar) and nitrogen (N₂) into the enclosed screening chamber, while simultaneously discharging air to reduce the oxygen content in the chamber to below a set threshold (typically ≤5%). This process is monitored in real time by an oxygen analyzer, and the opening and closing of the gas valve is automatically adjusted by a central controller to ensure that the entire screening process is in an oxygen-free environment. Some high-end models integrate an ultrasonic cleaning system, which uses high-frequency vibration to destroy the surface tension of the screen mesh, preventing the agglomeration and blockage of ultra-fine powders (such as 3D printed titanium alloy powder). The screening efficiency can be increased by more than 10 times, meeting stringent environmental requirements.

Cavity body: It isolates external air and prevents gas leakage. It is made of 304 or 316L stainless steel and is seamlessly welded. The surface is polished to reduce material adhesion and facilitate cleaning.

Sealing components: The feed inlet, discharge outlet, and access door are equipped with a dual sealing structure, with an inner layer of food-grade silicone gasket and an outer layer of fluororubber seal ring to ensure airtightness, with a gas leakage rate of ≤0.1%/h.

Observation window: It is made of explosion-proof tempered glass with sealing rubber strips, allowing real-time observation of the screening status of materials inside the chamber while meeting explosion-proof requirements.

Gas supply unit: including inert gas storage tank interface, pressure reducing valve, flowmeter, which can accurately control the gas injection rate and adapt to different inert gases such as nitrogen and argon.

Oxygen concentration monitoring unit: Equipped with a high-precision oxygen sensor, it continuously monitors the oxygen level within the chamber. When the oxygen content surpasses a predefined threshold, an automatic alarm is triggered.

Pressure balance unit: Equipped with pressure sensors and exhaust valves, it maintains a slight positive pressure within the chamber, preventing external air infiltration and avoiding damage to the chamber due to excessive pressure. Some high-end models include gas recovery devices that can recycle inert gases, reducing operating costs.

Provide screening power and determine screening efficiency and accuracy.

Excitation source: A vertical explosion-proof vibration motor is used, with eccentric weights mounted on both the upper and lower ends of the motor. By adjusting the phase angle of the weights, the motion trajectory of the material on the screen surface can be controlled, accommodating materials with different particle sizes ranging from 10 to 600 mesh.

Shock absorption component: The motor and the cavity are connected through a rubber shock pad to reduce the vibration transmitted to the equipment base, reduce noise, and protect the motor to extend its life.

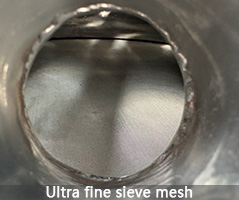

Screen mesh fixing structure: It adopts a quick-release screen mesh press plate, paired with a tensioning device, to ensure that the screen mesh is flat and free of slack; the screen mesh material can be selected from 316L stainless steel metal woven mesh, polyurethane mesh, or nylon mesh. Some models support multiple layers of screen mesh, allowing for multi-grain size classification at the same time.

Solve the problem of ultra-fine or viscous material blocking the screen, and improve screening efficiency.

Ultrasonic screen cleaning device: Install an ultrasonic transducer under the screen to destroy the agglomeration force of materials through high-frequency vibration, avoiding screen blockage. It is especially suitable for screening ultra-fine materials such as 3D printing metal powder and nanomaterials, and can increase screening efficiency by 2 to 10 times.

Airflow back-blowing device: Some models have back-blowing air holes on the side of the chamber, which use inert gas pulses to back-blow the surface of the screen, assisting in the removal of residual materials and reducing material loss.

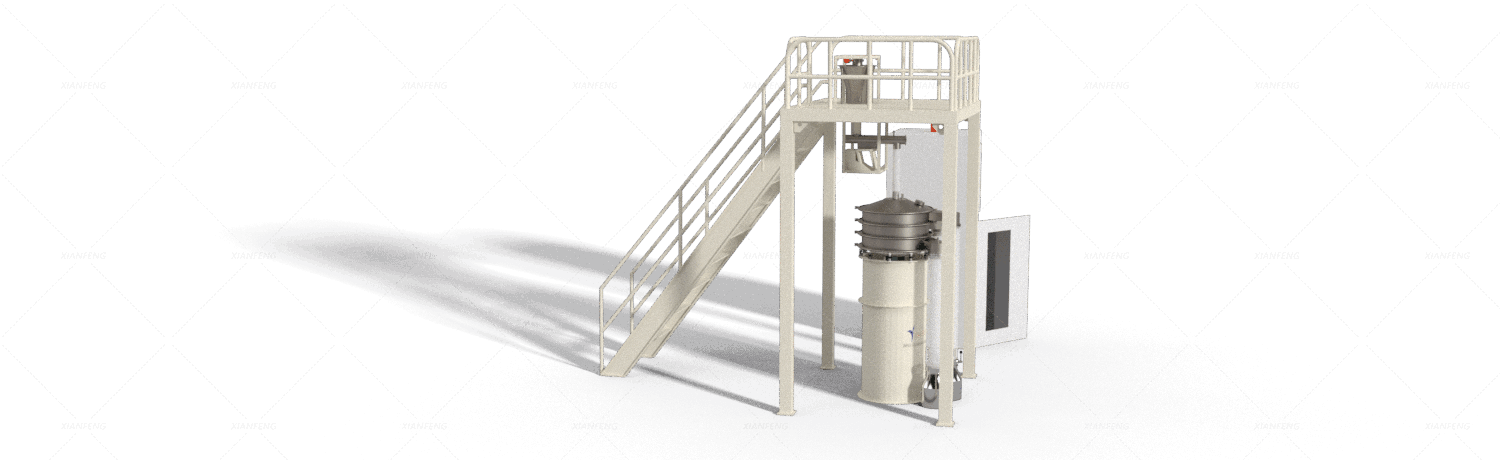

Realize automatic operation and safety interlocking, reduce manual intervention.

PLC control cabinet: Integrated touch screen, which can set parameters such as screening time, vibration frequency, oxygen content threshold, etc., and supports one-click start and stop; it also has data storage function for easy traceability.

Safety interlock function: When the oxygen content exceeds the standard, the motor is overloaded, or the sealing door is not closed tightly, the equipment will automatically stop running and sound and light alarms to prevent safety accidents; some models support remote monitoring, allowing real-time viewing of operating parameters and remote debugging.

Ensure stable operation of equipment and adapt to different workshop environments.

Rigid base: It is welded with steel sections and coated with anti-static paint on the surface. The grounding resistance is ≤4Ω to prevent static electricity accumulation (suitable for flammable and explosive materials).

Adjustable feet: The bottom of the base is equipped with height adjustable feet, which can be adjusted according to the flatness of the workshop floor to ensure horizontal operation of the equipment and avoid material deflection caused by tilt.

1. Metal powder processing

Used for the classification of easily oxidizable metal powders such as titanium alloy, stainless steel, and aluminum powder. For example, in the field of 3D printing, it is necessary to control the powder particle size to 50-150μm while ensuring an oxygen content of <200ppm. Inert gas protection can avoid the performance degradation of printed parts caused by powder oxidation.

2. Electronic material processing

For semiconductor materials such as silicon powder and graphite powder, it is important to prevent dust explosions and maintain material purity. For example, in the production of lithium batteries, the screening of anode materials needs to be carried out in a nitrogen environment to avoid reacting with moisture in the air to generate hydrogen gas.

3. Food and pharmaceutical industry

It is used to handle functional powder which is easy to be oxidized (such as probiotics, vitamins), and flammable and explosive pharmaceutical intermediates (such as nitrocellulose). The equipment meets the requirements of GMP certification and can be equipped with CIP online cleaning system.

4. Specialty Chemicals Screening

Suitable for high-value materials such as nanomaterials and precious metal catalysts, it reduces loss while ensuring production safety. For example, screening of nano silver wires needs to be carried out in an argon environment to prevent oxidation, which can lead to a decrease in conductivity.

Technical Advantages and Industry Value

1. Improved safety: By using inert gas replacement and explosion-proof design (such as ATEX certification), the risk of dust explosion is eliminated, making it particularly suitable for hazardous environments where dust clouds persist;

2. Material quality assurance: The oxygen content can be controlled below 10ppm to avoid oxidation discoloration and performance degradation, meeting high-end material production standards;

3. Environmental protection and energy saving: The fully enclosed structure ensures dust emissions <1mg/m³, while the inert gas can be recycled, reducing operating costs;

High efficiency and stability: The screening accuracy is up to 99.5%, the processing capacity is 20-40% higher than that of traditional vibrating screen, and the maintenance period is extended to more than 6 months.

Key parameter matching

Select the mesh size (usually 10-600 mesh) and number of layers based on the material characteristics (such as particle size, humidity, and fluidity);

When handling flammable and explosive materials, it is necessary to equip with explosion-proof motors, anti-static screens, and grounding devices;

For high purity requirements (such as electronic grade materials), 316L stainless steel should be used and passivated.

Suggestions for daily maintenance

Regularly check the aging condition of seals, and it is recommended to replace the silicone gasket once every quarter;

Clean the oxygen sensor probe monthly to avoid dust pollution affecting detection accuracy;

Conduct tension tests on the screen mesh every six months and replace any loose or damaged screen mesh in a timely manner

The core difference lies in the environmental control capability: ordinary vibrating screens are open or semi-open structures that only achieve screening functions and cannot isolate air; while inert gas-protected vibrating screens use a fully enclosed cavity + inert gas replacement to control the oxygen content in the cavity at 10ppm~5% (adjustable as needed), which can avoid the deterioration or safety accidents of easily oxidizable, flammable and explosive materials during screening, while meeting the cleanliness requirements of high-purity materials.

It can be fully integrated into automated production lines, requiring the reservation of three types of interfaces in advance:

Material interface: The inlet/outlet should be equipped with flange interfaces (compliant with DN standards) to facilitate docking with upstream mixing equipment and downstream packaging equipment, and should be equipped with valves to control material flow;

Electrical interface: PLC communication interface is provided, which can be linked with the workshop central control system to achieve remote start-stop and parameter monitoring;

Gas interface: If inert gas (such as nitrogen) needs to be prepared on site, a nitrogen generator docking interface (usually DN25~DN50) needs to be reserved, and a gas pressure sensor needs to be equipped to achieve interlock control between gas supply and equipment operation.

23 years of experience specializing in screening and conveying equipment manufacturing [Rich experience, providing complete customized solutions]

40,000 square meter factory, a genuine source manufacturer [No middlemen, lower prices]

50 technical patents, CE/ISO certifications [Technology proven, trustworthy]

20 years of export experience, equipment exported to over 70 countries worldwide [Full-process support from a professional team]

Ensure your product quality and reputation.

Our professional solutions are designed to maximize your production efficiency.

Reduce production downtime, resource waste, and maintenance issues.