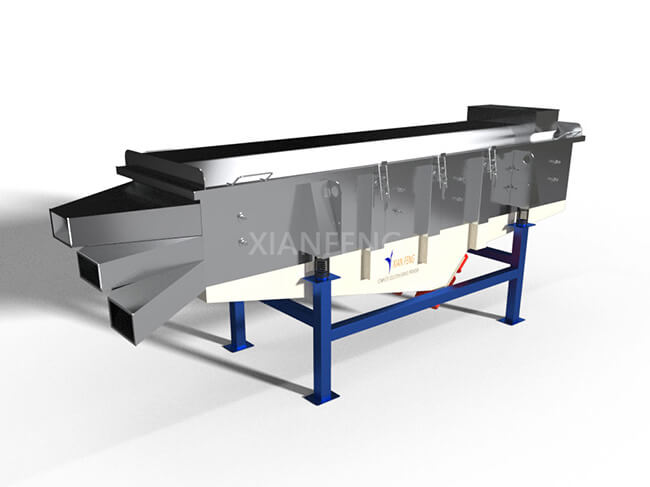

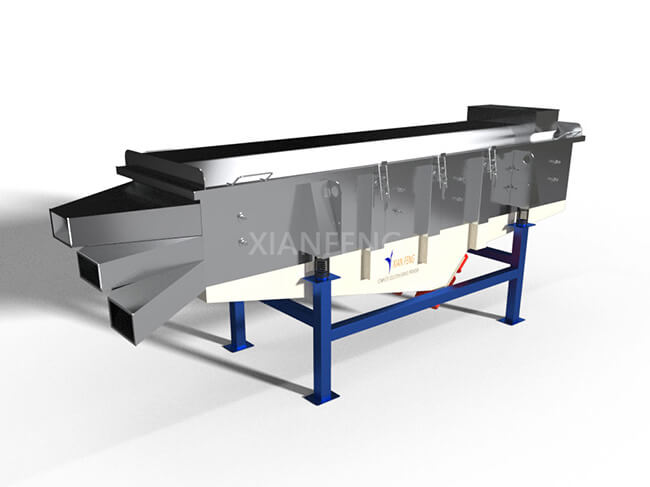

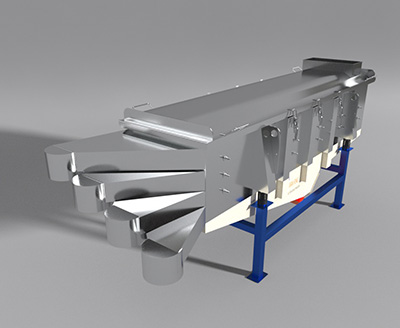

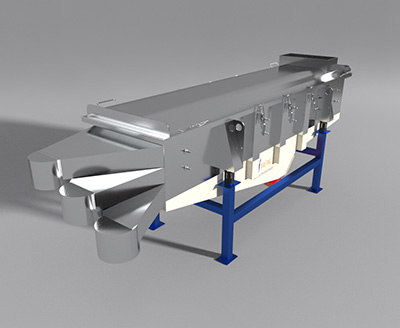

Rectangular Vibrating Screen (also known as Linear Vibrating Screen)

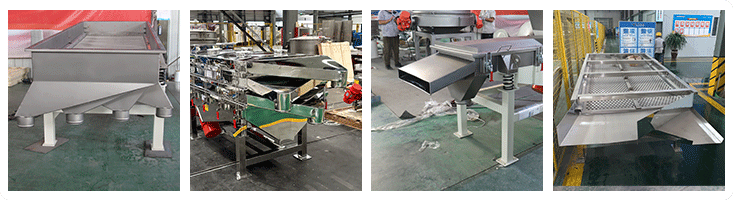

Features a fully enclosed rectangular structure. Commonly used for:Dry Materials: Coarse screening, impurity removal, dust extraction, and powder separation of granules and powders.Wet Materials: Dewatering.Utilizes a dual-motor drive, propelling materials in a bouncing motion across the screen surface for rapid throughput. A single unit delivers high-capacity screening with strong durability.Widely applied in the food, chemical, pharmaceutical, and mining industries.This is customizable equipment based on specific requirements. XianFeng's vibratory screening equipment is seamlessly compatible with a range of conveyors, mixers, and other key processing equipment, providing you with a tailored integrated solution.

Coal, ore pellets, glass, quartz sand, soil, sand, etc.

Kaolin, limestone, clay, iron powder, cement, gypsum powder, etc.

Wheat, corn, bran, rice, feed, grain pellets, etc.

Fertilizer, soda ash, baking soda, plastic pellets, rubber pellets, PVC pellets, etc.

Sugar, salt, potato chips, nuts, freeze-dried food, pet food, dried meat, flower petals, etc.

Traditional Chinese Medicine slices, capsules, tablets, raw drug powder, vitamin granules, etc.

Pulp, wastewater, etc.

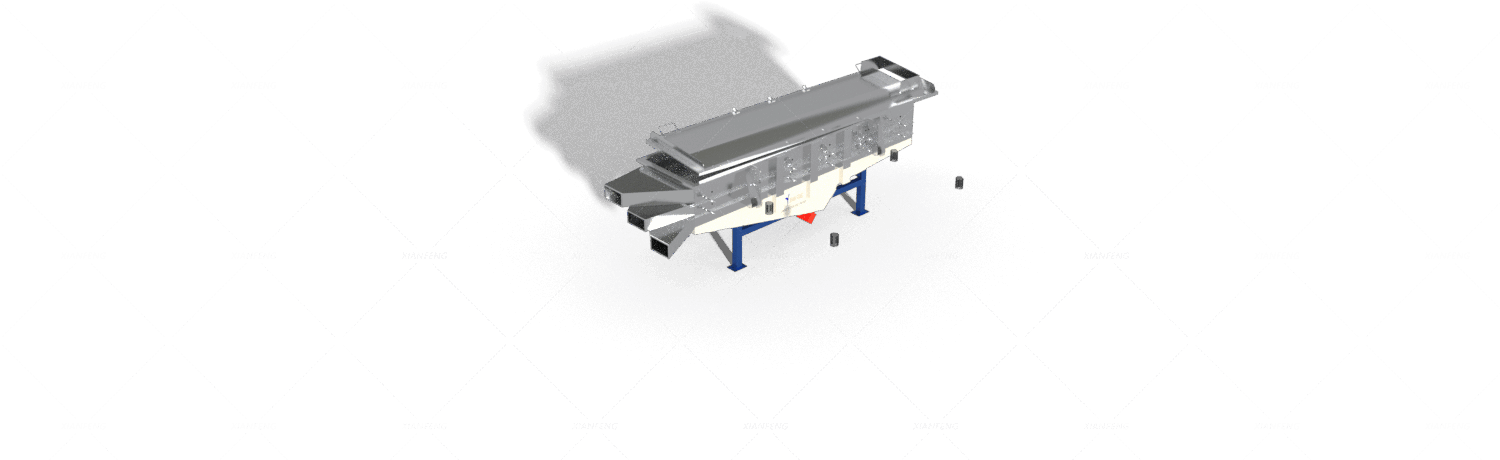

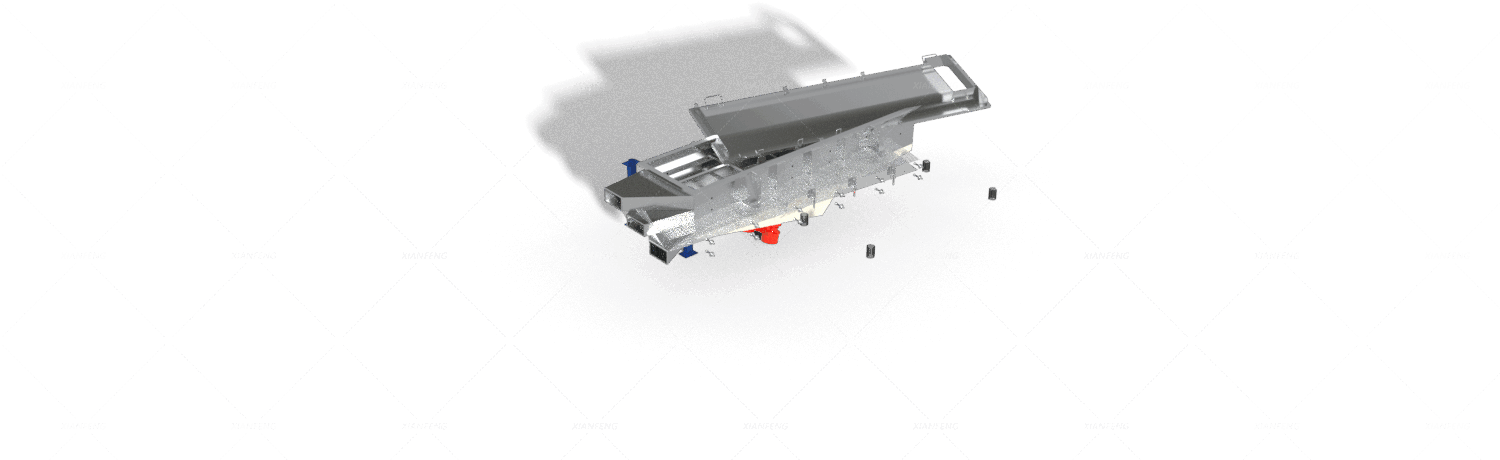

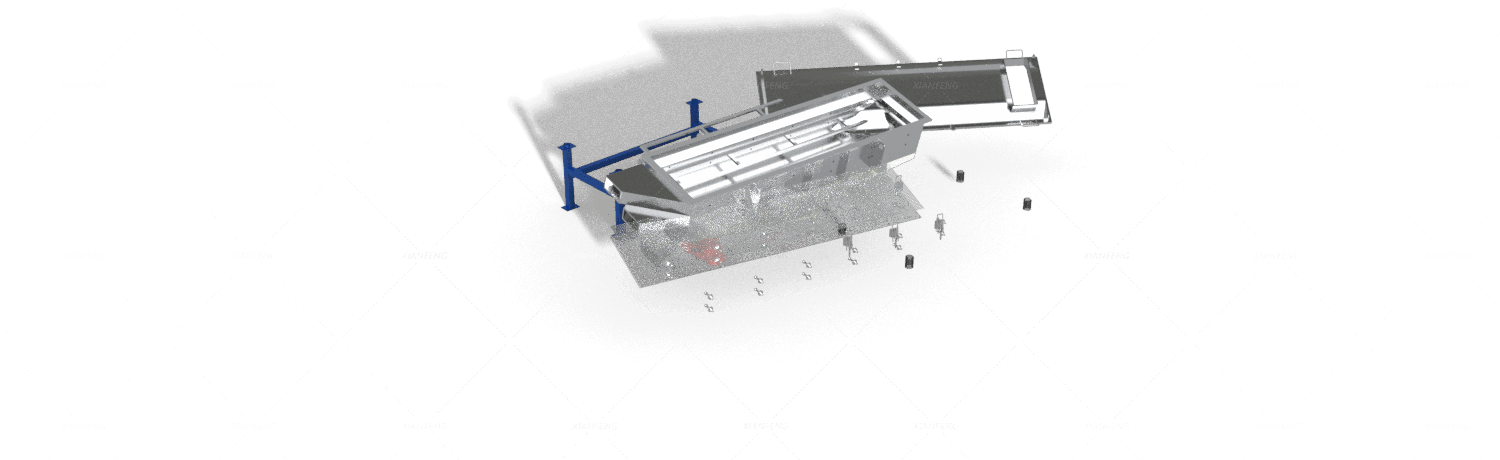

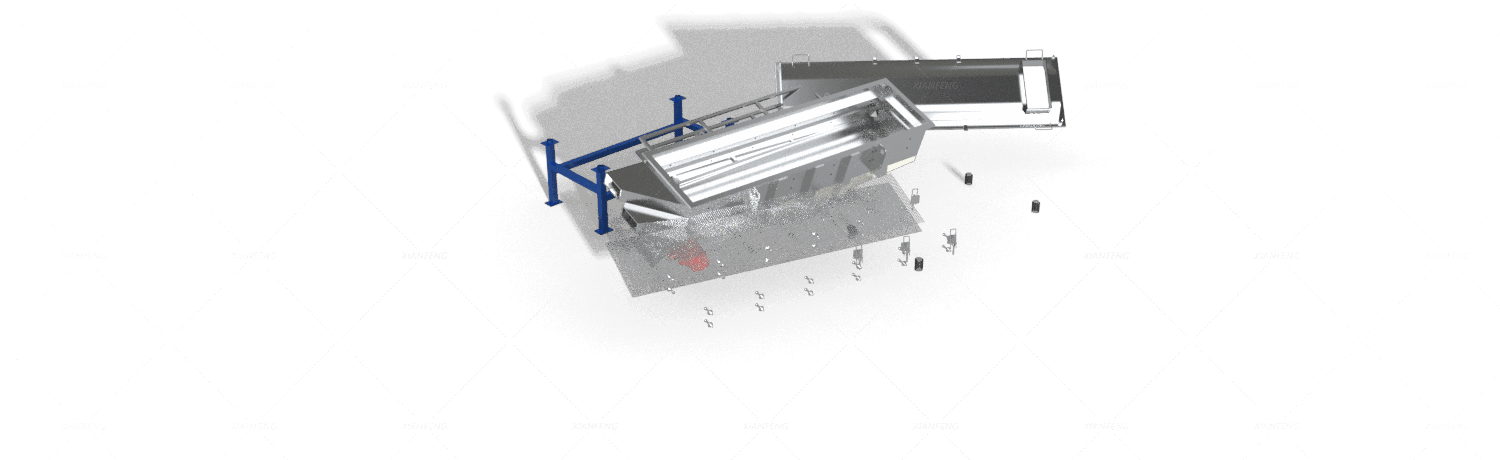

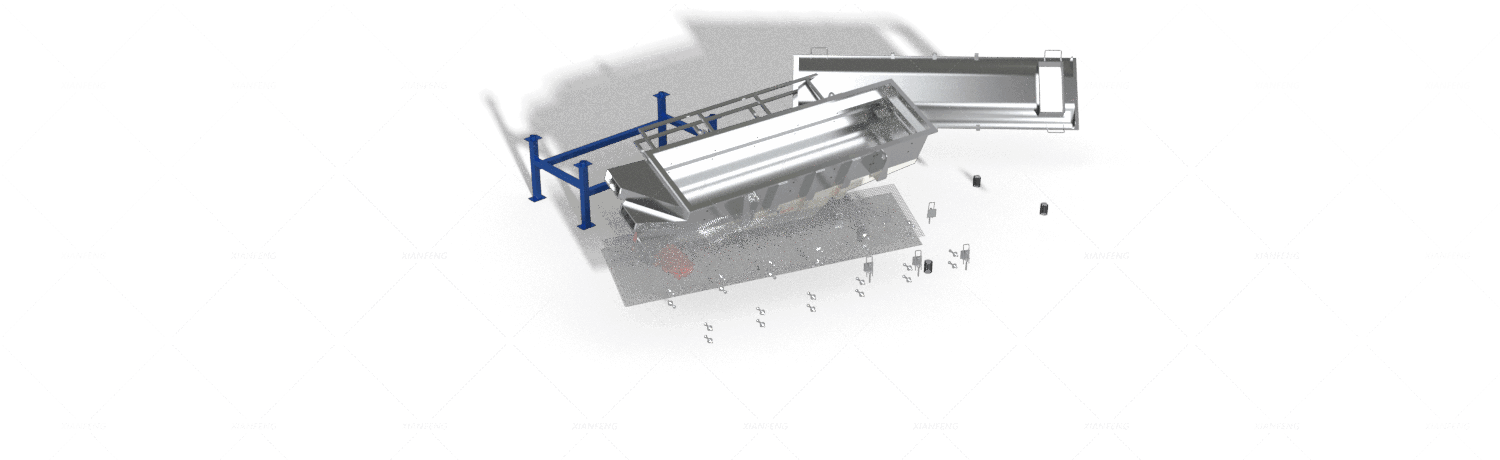

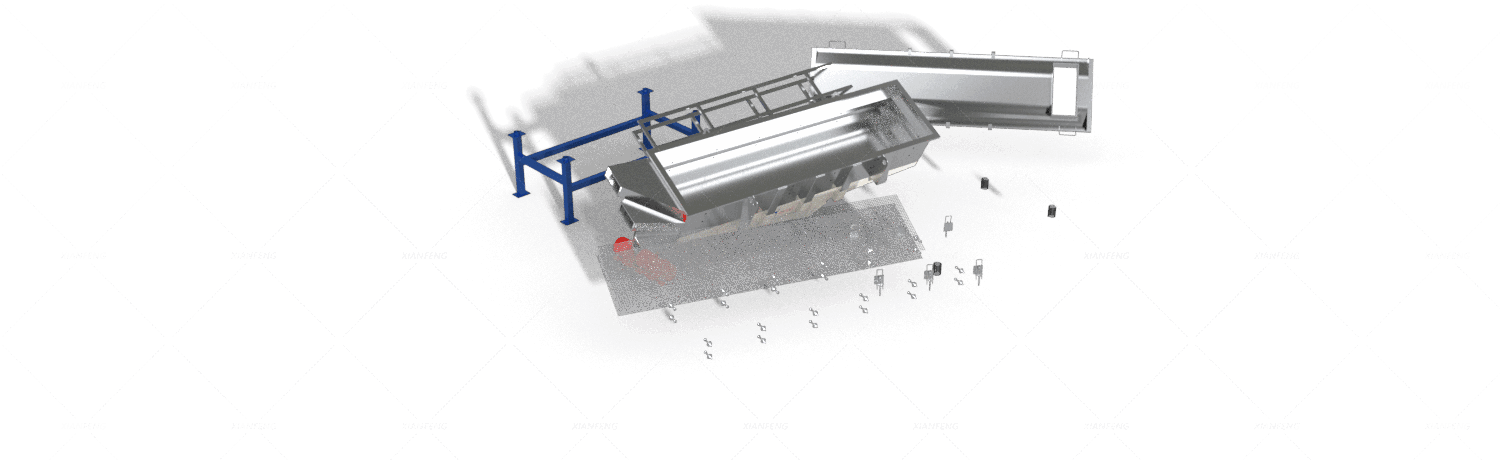

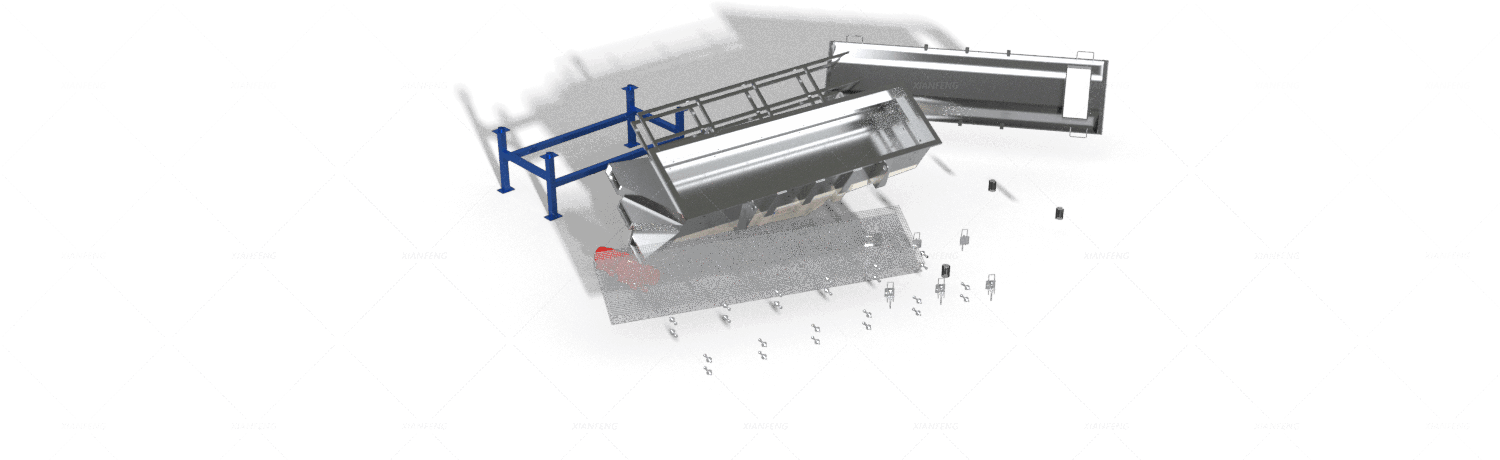

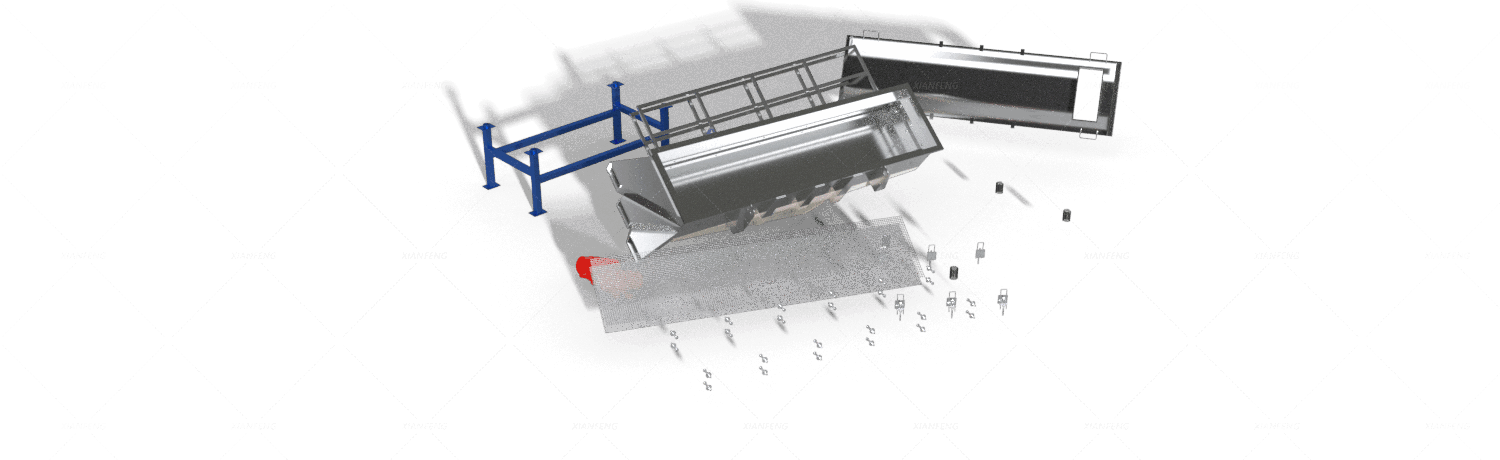

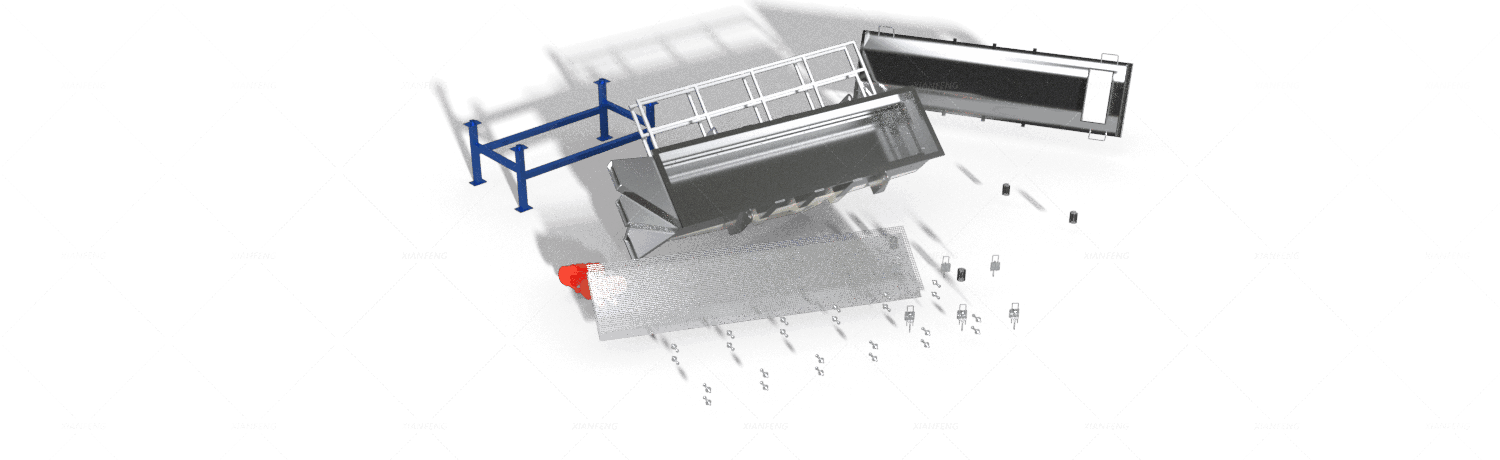

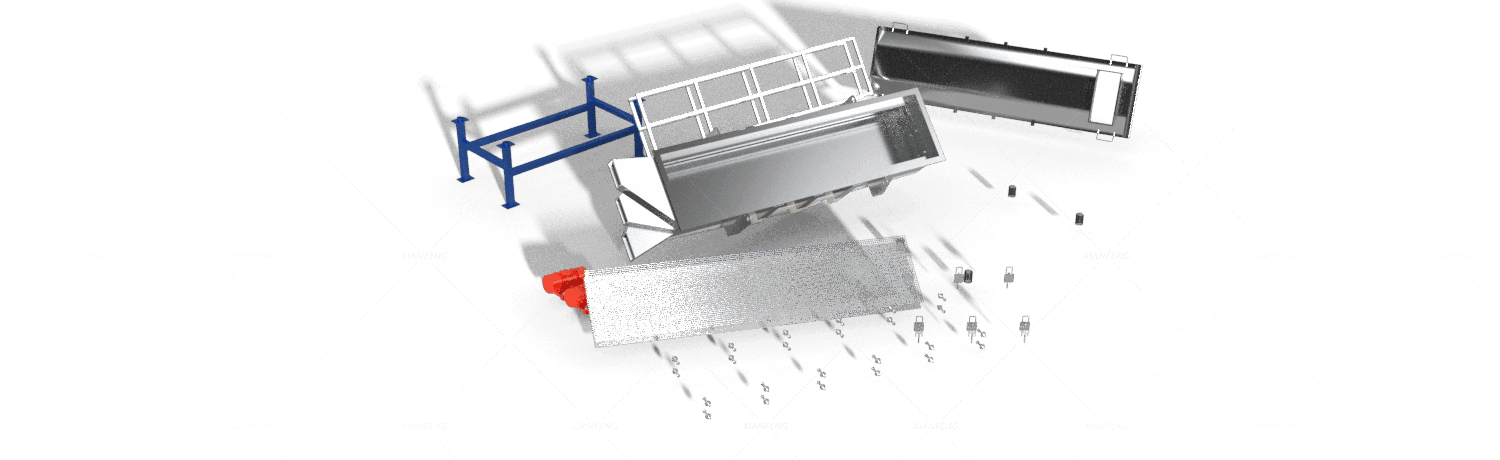

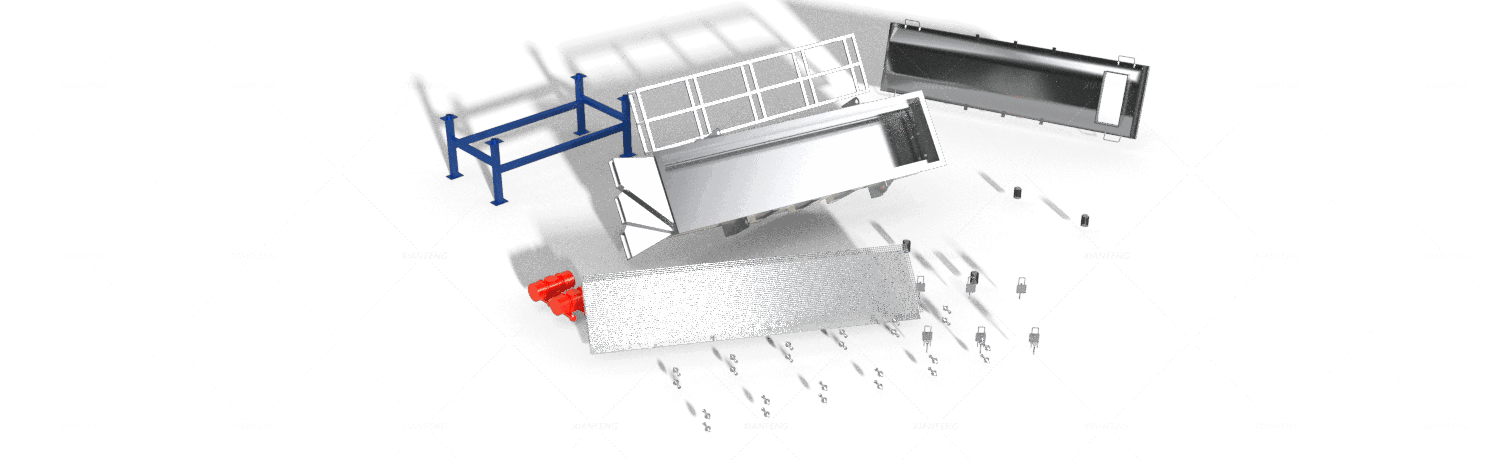

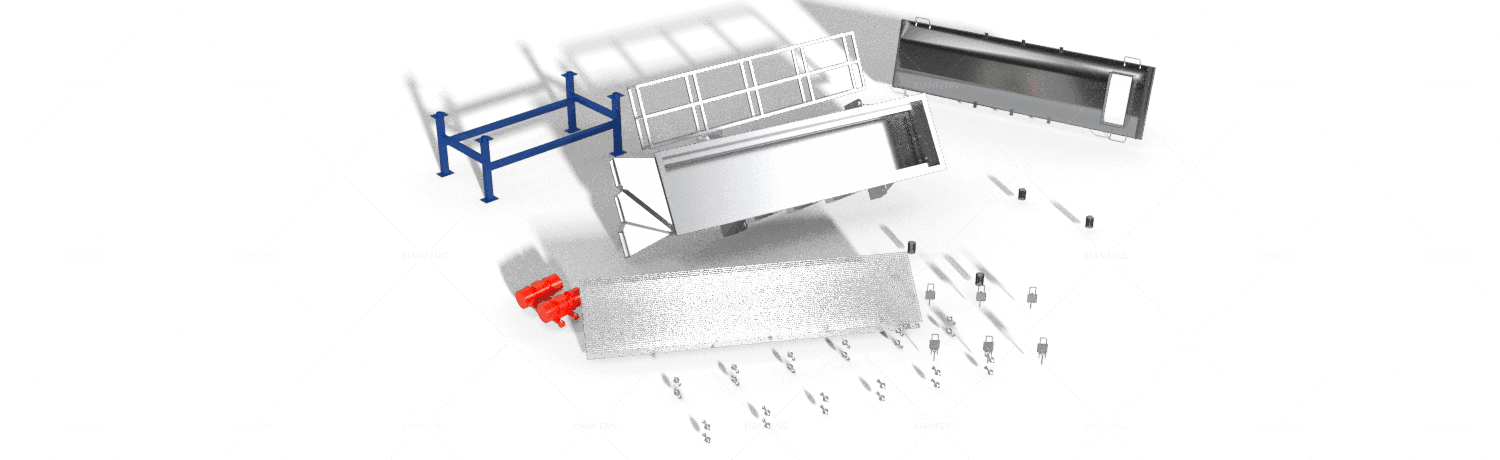

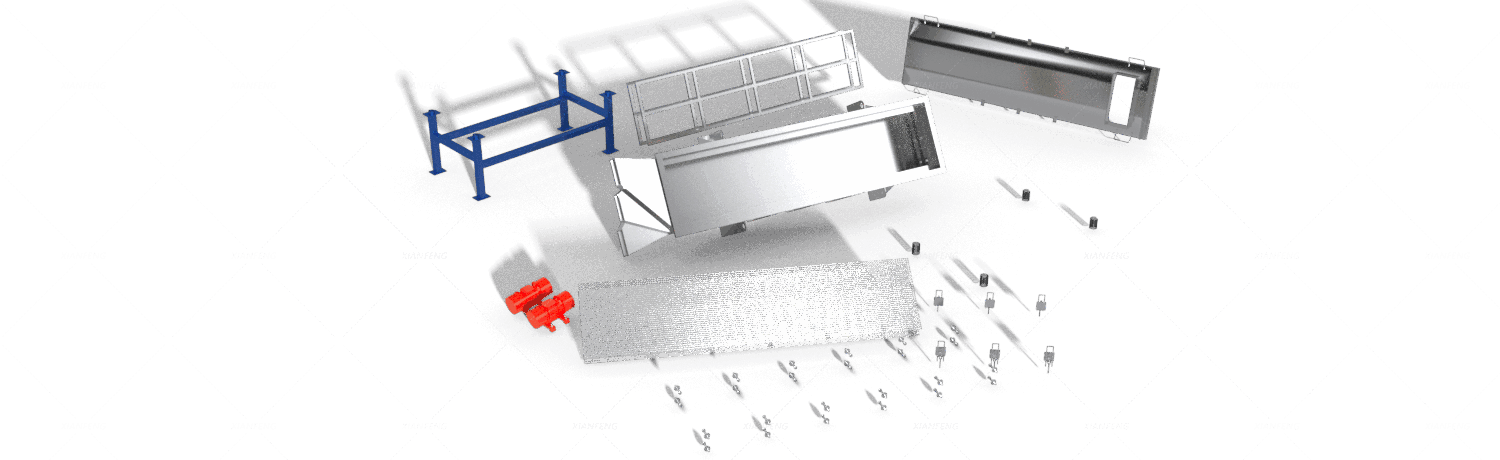

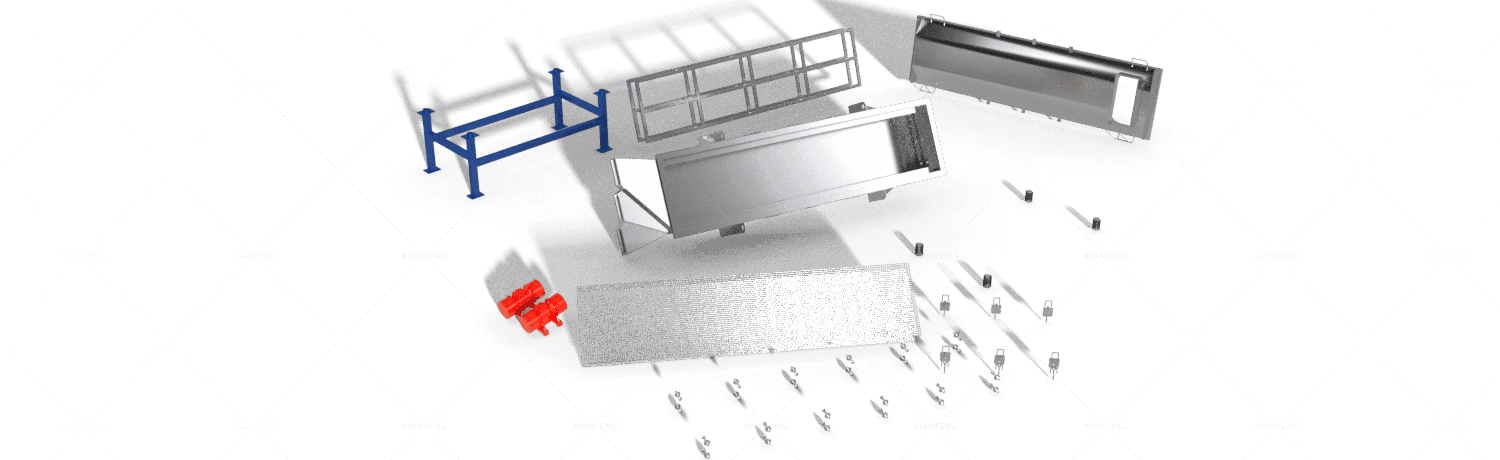

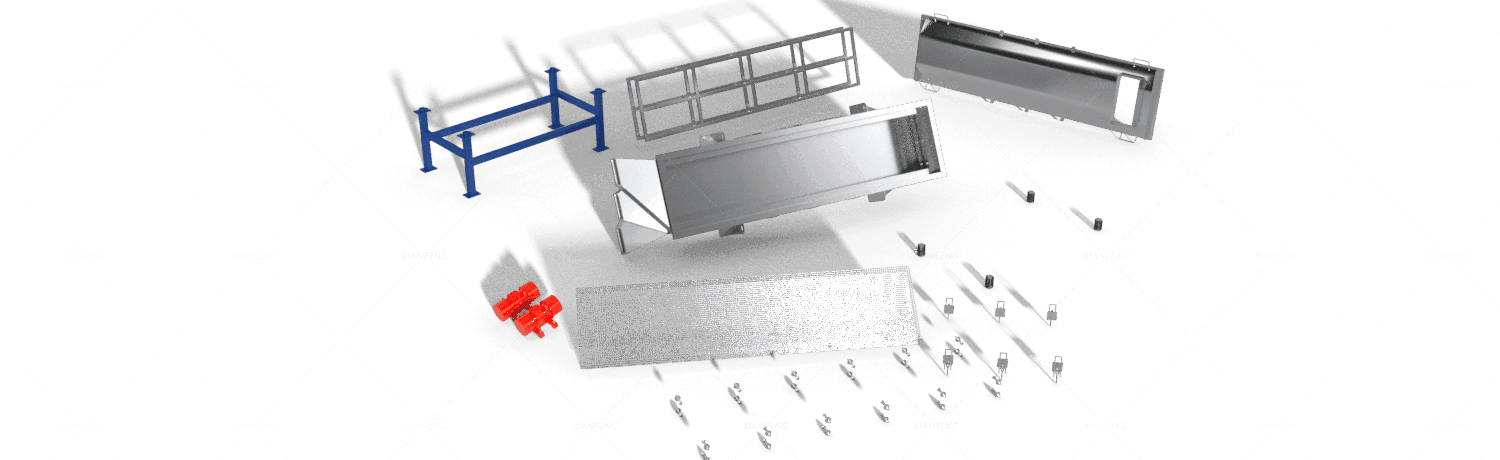

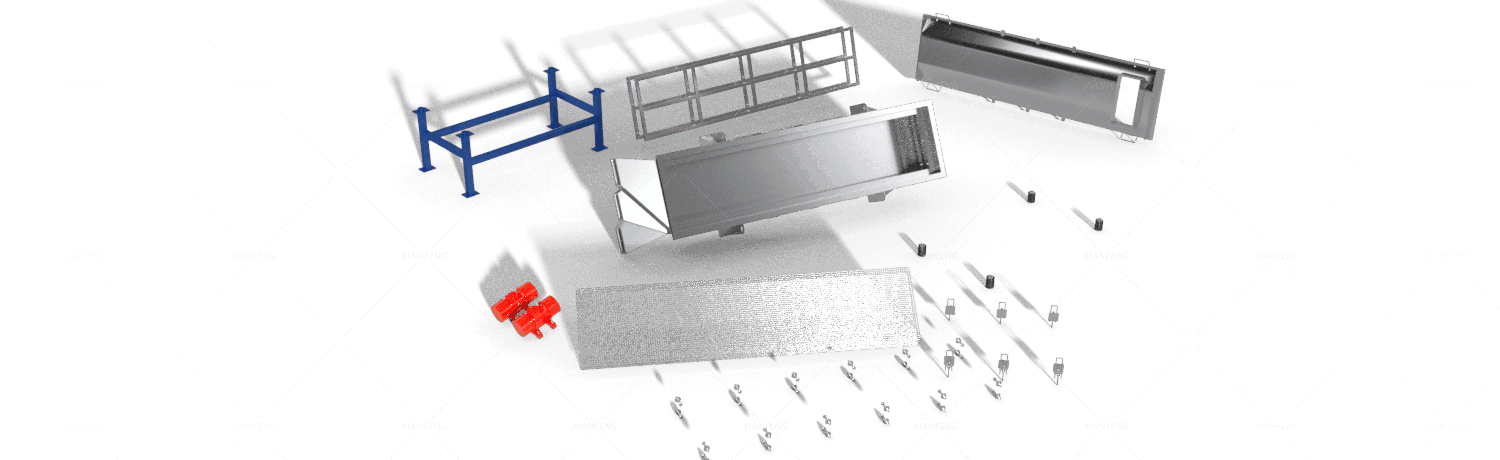

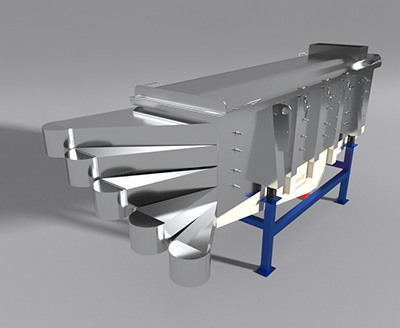

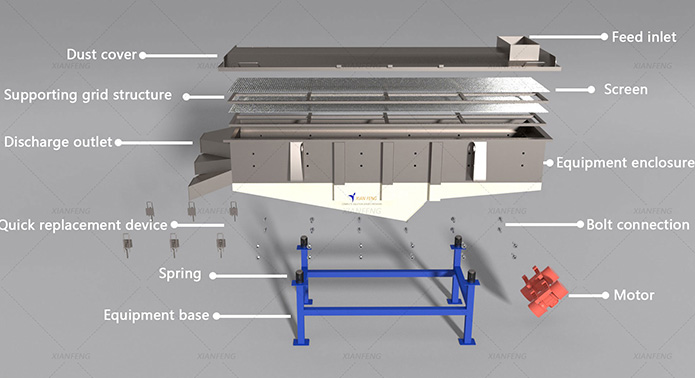

Feed inlet

Screen mesh

Grid support and fixation

Discharge outlet

Base and spring

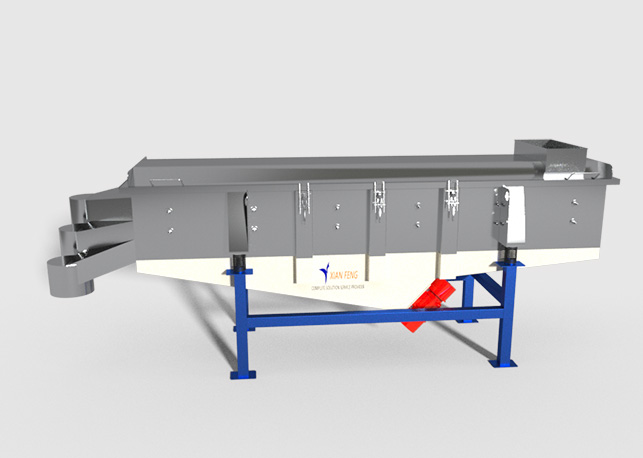

Motor

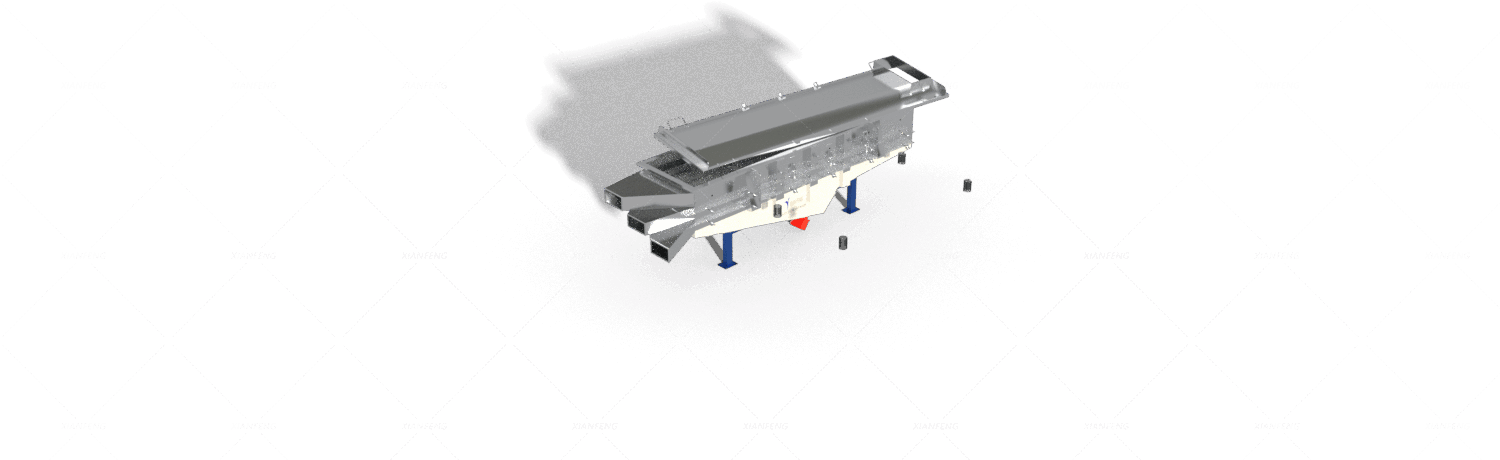

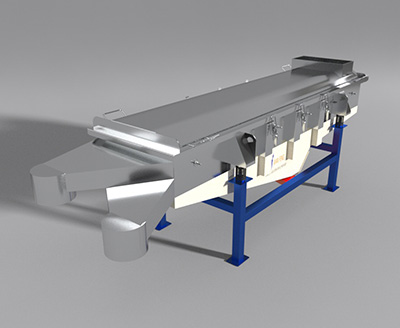

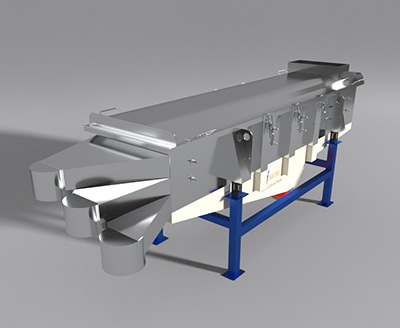

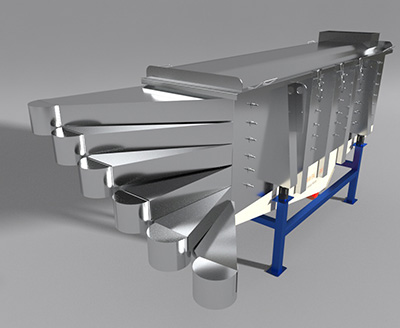

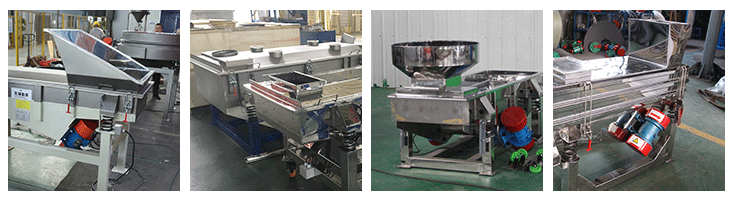

Various types of feed ports can be customized as needed

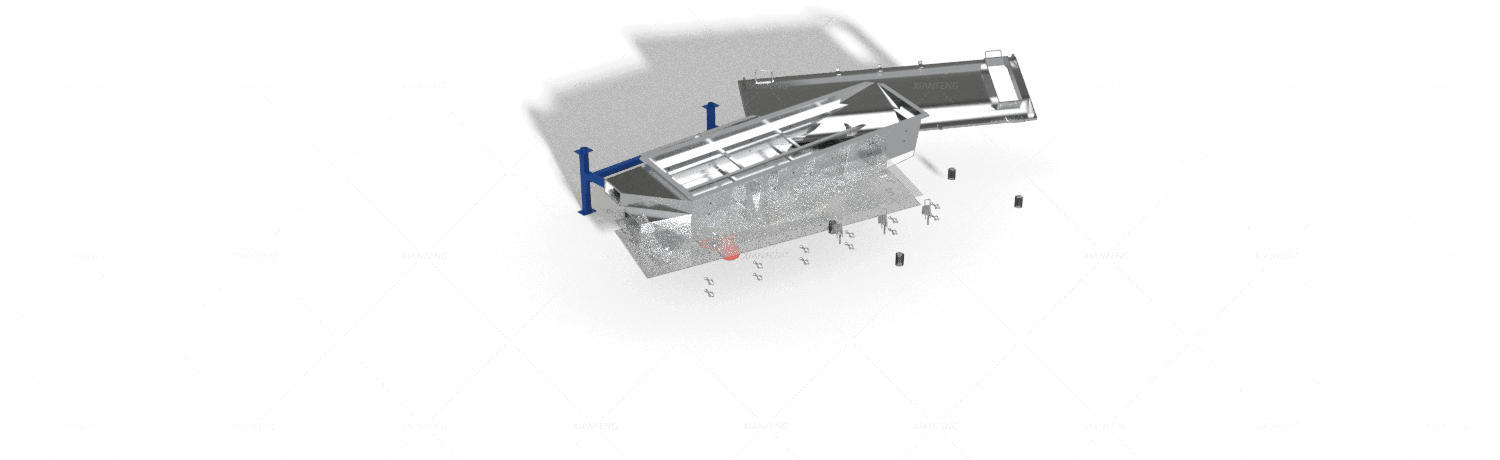

Customizable V-shaped discharge buffer to prevent direct impact of materials on the screen mesh

The feeding port can be customized with connecting flanges and other accessories to connect upstream and downstream equipment

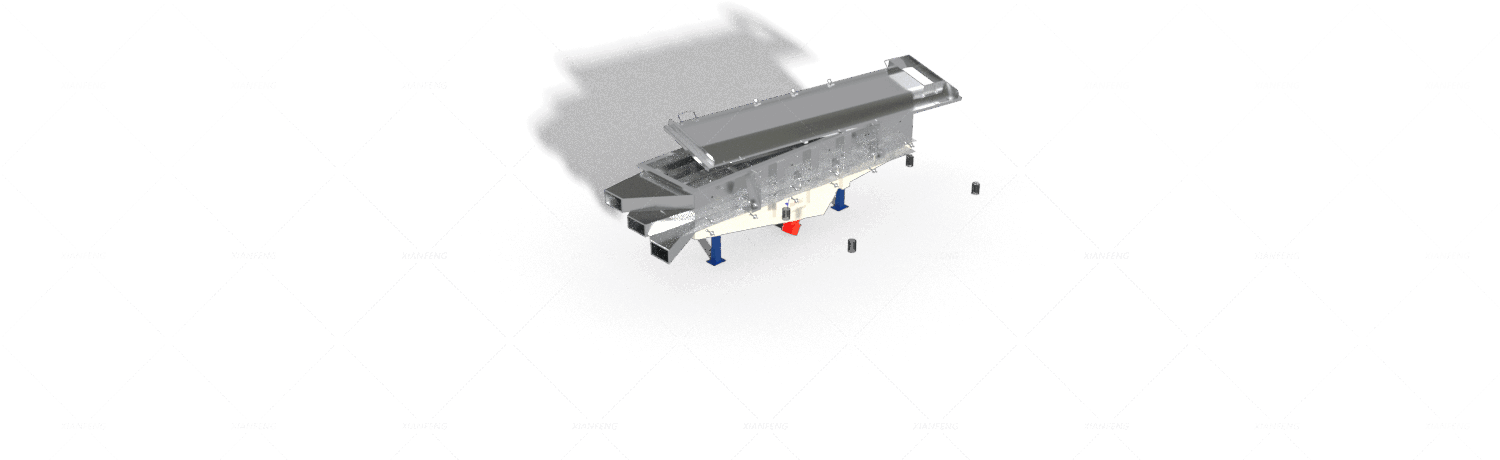

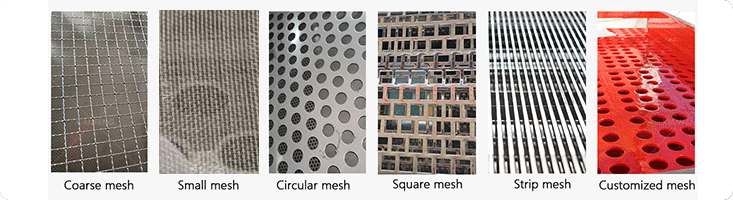

Commonly used metal woven mesh, punched plate screen mesh and other processes can be customized with different types of mesh holes to meet screening needs

Special materials can be selected from different types of materials, such as 316 stainless steel, polyurethane material, PP plastic material, special coatings (such as PTFE, sandblasting), etc

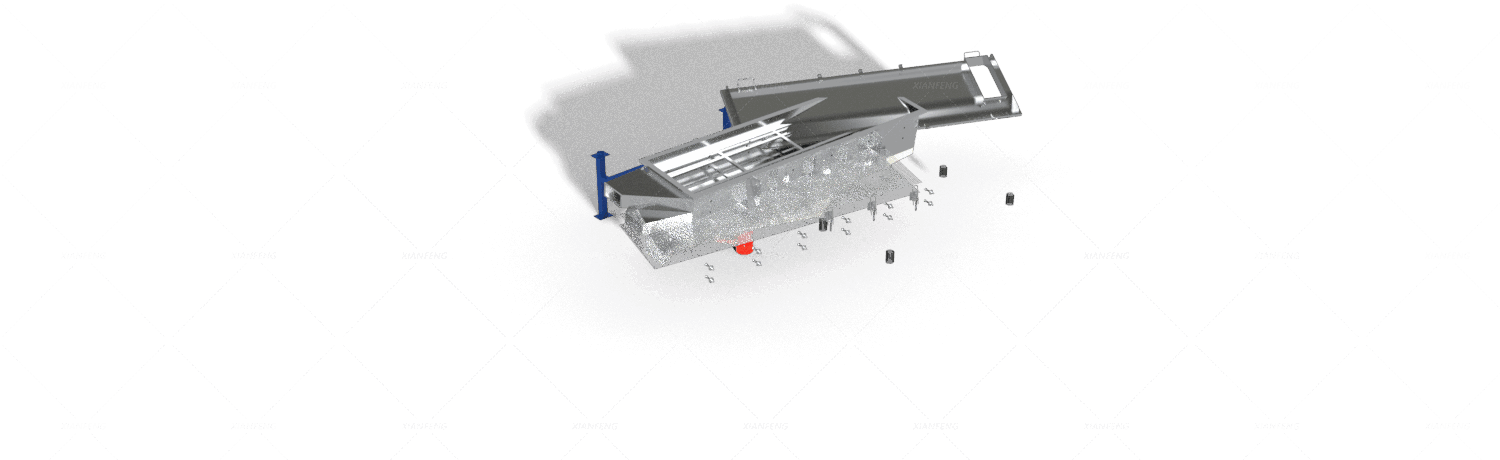

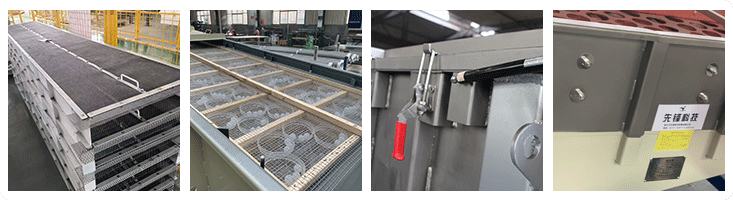

The grid structure of the linear screening machine usually adopts steel or wooden grid structure, V-shaped groove structure, etc.

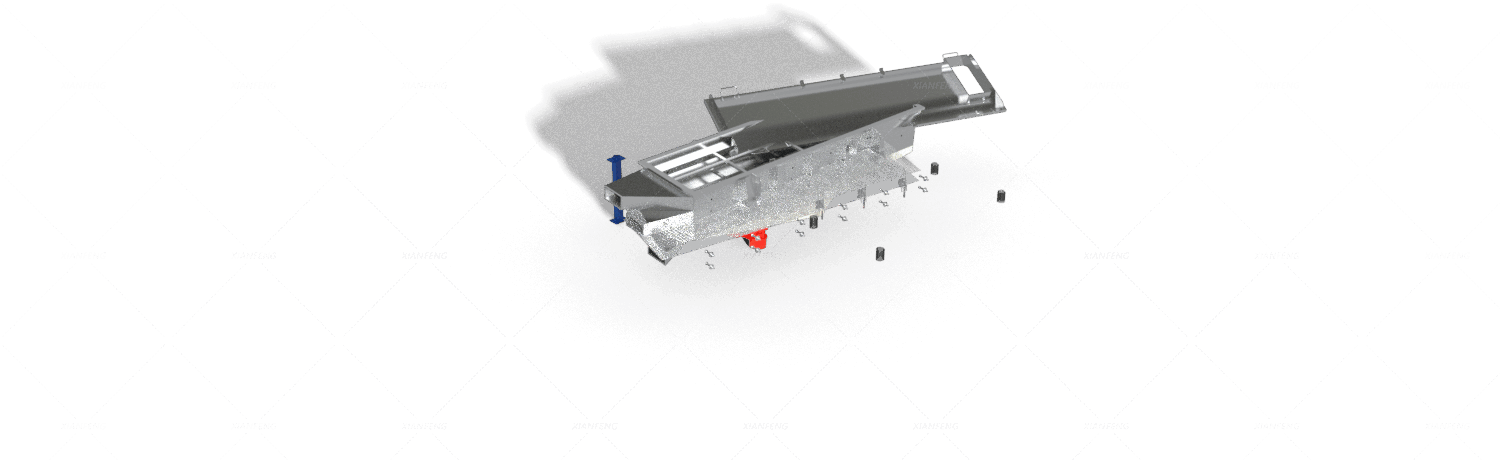

Customized quick opening device for easy replacement of screen mesh according to needs, and customized hydraulic rod device for real-time observation of material screening situation

Hook plate connection, bolt fixation, convenient and secure

Customization of different types of discharge ports to meet various production needs

Carbon steel or stainless steel bracket provides stable support, and the tilt angle of the vibrating screen can be customized according to the needs

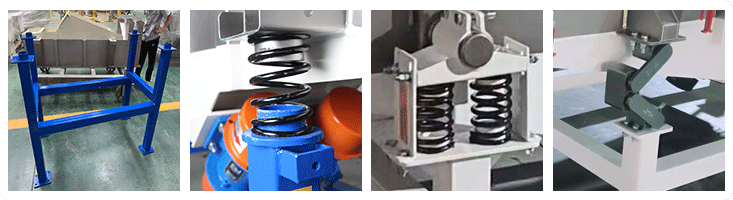

Usually, single or double sets of high steel metal springs are used, and Tenida robotic arm springs can also be customized to reduce noise, resist resonance, and cope with corrosive production environments.

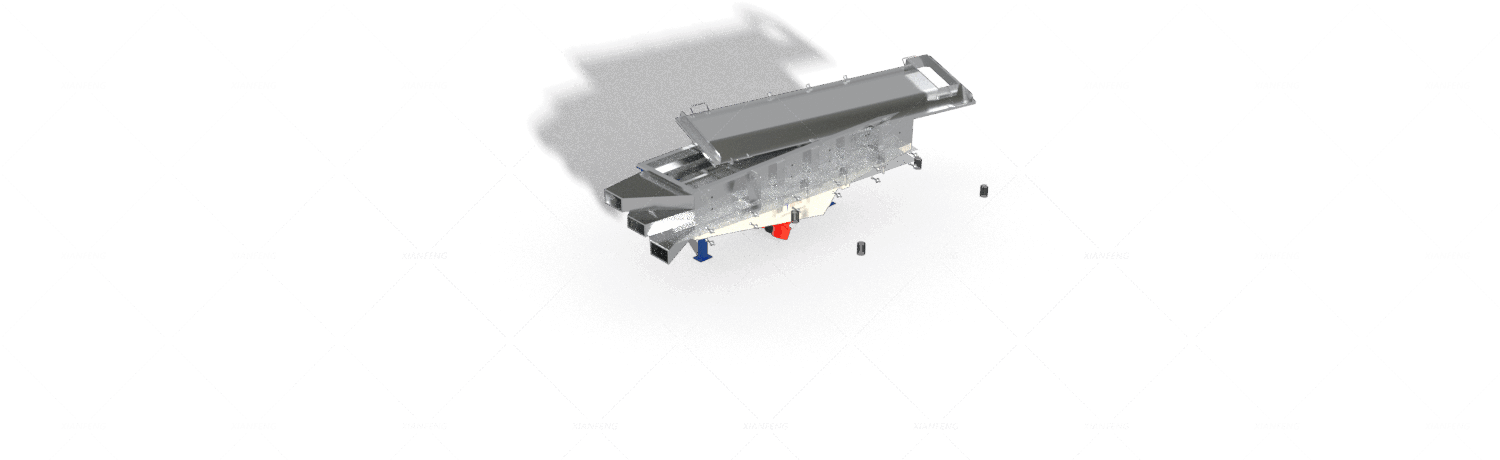

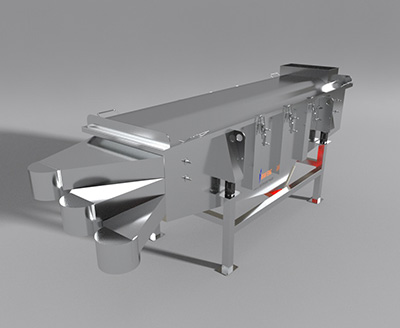

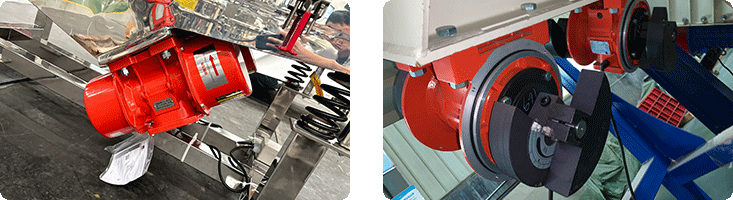

Using two imported Ouli Wolong horizontal motors, the noise is lower, the efficiency is higher, and the long-term operation is fault free to ensure continuous production

Customized explosion-proof motors can be used to meet safety production requirements for special production environments with dust or gas

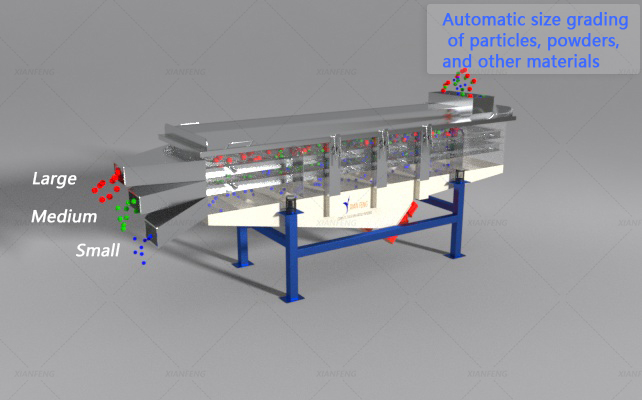

The core working principle of a linear vibrating screen is to drive the screen box to perform reciprocating vibration along a linear trajectory through the excitation force generated by a vibration motor. This causes the material to be thrown and advanced in a linear direction on the screen surface, and utilizes the "screening difference" between materials of different particle sizes and the screen mesh to achieve grading, impurity removal, or screening. The entire process can be broken down into "power generation → vibration transmission → material movement → screening separation".

The linear screening machine is composed of a vibration motor, a screen box and frame, a screen mesh system, a vibration reduction device, a bracket, a base, and other components.

As the core power source, it typically employs two horizontal vibration motors rotating synchronously in opposite directions, generating excitation force through eccentric blocks to drive the screen body movement. XIANFEGN utilizes imported Ouli Wolong brand, with adjustable excitation force and support for multiple installation inclinations to accommodate different screening needs. The motor base is connected using high-strength bolts to ensure operational stability.

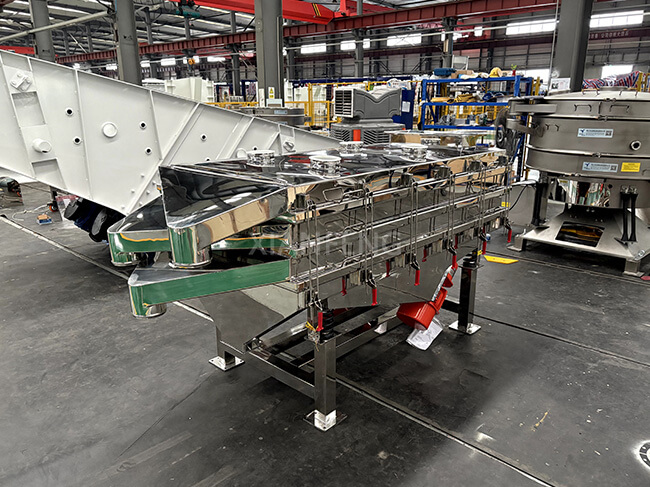

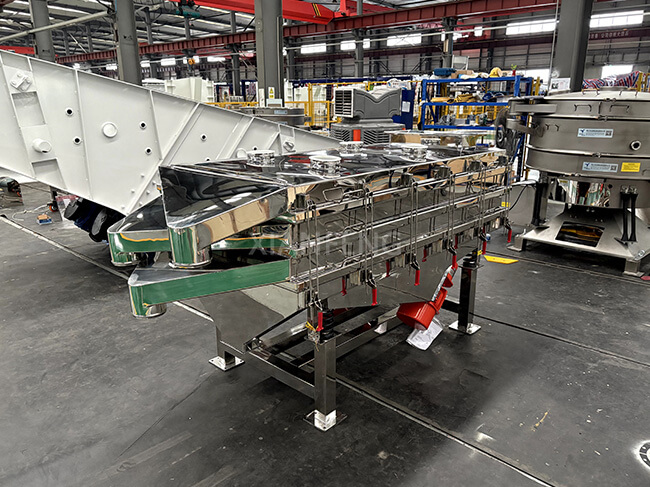

Screen box: It is welded from high-quality steel plates, with reinforced structural design on the side panels, providing high strength and fatigue resistance. Some models (such as the DZSF series) can be configured with all stainless steel materials (304/316) to meet the hygiene requirements of the food and pharmaceutical industries.

Screen frame: Typically, the screen mesh is supported by a pine or metal frame. Some models feature a detachable design, facilitating quick and easy replacement of the screen mesh.

Material: Optional stainless steel woven mesh, punched screen plate, polyurethane screen mesh, etc., suitable for different material characteristics (such as corrosivity, high hardness).

Number of layers: Supports screening with 1-5 layers, capable of simultaneously separating 2-6 particle size grades, with a focus on large particle screening.

Tensioning method: A special truss structure design is adopted, such as spring tensioning or bolt fixation, to ensure quick installation and stable operation of the screen mesh.

It is typically composed of rubber springs or metal springs, installed between the screen body and the bracket, which can reduce the noise during equipment operation (≤85dB) and minimize the impact on the foundation structure. Some high-end models adopt composite springs, balancing stiffness and cushioning performance.

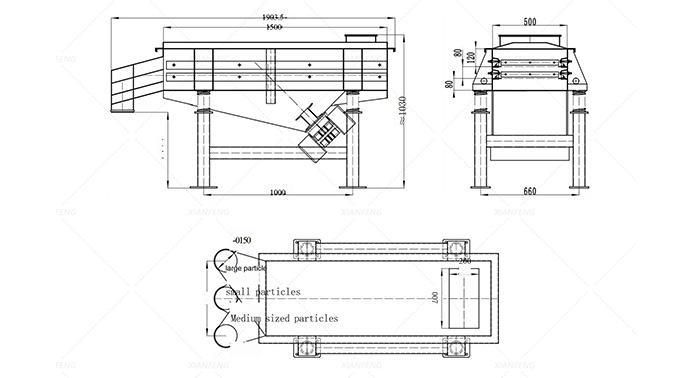

The support made of carbon steel or stainless steel provides stable support, and the base can be integrated with a leveling device to ensure precise adjustment of the installation inclination (0°-15°) of the screen body. Some models support modular design, facilitating on-site assembly and maintenance.

Linear vibrating screen | frozen meat dry screening

Rectangular vibrating screen

Vibration screens | Iron sand screening

slurry filtration | Stainless steel vibrating screen

| Model | Meshsize(mm) | Meterialsize(mm) | Sieve angle(°) | Amp. (mm) | Layers | Power(kw) | |

| XFZ0520 | 500*2000 | 0.074~10 | 0°~7 | 4~8 | 1~5 | 2*(0.37~0.75) | |

| XFZ0525 | 500*2500 | 0.074~10 | 0°~7° | 4~8 | 1~5 | 2*(0.37~0.75) | |

| XFZ0530 | 500*3000 | 0.074~10 | 0°~7° | 4~8 | 1~5 | 2*(0.55~1.1) | |

| XFZ0535 | 500*3500 | 0.074~10 | 0°~7° | 4~8 | 1~5 | 2*(0.55~1.1) | |

| XFZ1020 | 1000*2000 | 0.074~10 | 0°~7° | 4~8 | 1~5 | 2*(0.55~1.1) | |

| XFZ1025 | 1000*2500 | 0.074~10 | 0°~7° | 4~8 | 1~5 | 2*(1.1~1.5) | |

| XFZ1030 | 1000*3000 | 0.074~10 | 0°~7° | 4~8 | 1~5 | 2*(1.1~1.5) | |

| XFZ1035 | 1000*3500 | 0.074~10 | 0°~7° | 4~8 | 1~5 | 2*(1.5~2.2) | |

| XFZ1040 | 1000*4000 | 0.074~10 | 0°~7° | 4~8 | 1~5 | 2*(1.5~2.2) | |

| XFZ1225 | 1200*2500 | 0.074~10 | 0°~7° | 4~8 | 1~5 | 2*(1.5~2.2) | |

| XFZ1230 | 1200*3000 | 0.074~10 | 0°~7° | 4~8 | 1~5 | 2*(1.5~3) | |

| XFZ1235 | 1200*3500 | 0.074~10 | 0°~7° | 4~8 | 1~5 | 2*(1.5~3) | |

| XFZ1530 | 1500*3000 | 0.074~10 | 0°~7° | 4~8 | 1~5 | 2*(2.2~3) | |

| XFZ1535 | 1500*3500 | 0.074~10 | 0°~7° | 4~8 | 1~5 | 2*(2.2~3) | |

| XFZ1540 | 1500*4000 | 0.074~10 | 0°~7° | 4~8 | 1~5 | 2*(2.2~3) | |

Material Particle Size:

Fine particles (≤100 mesh): Prioritize multi-layer screens (e.g., 3–5 layers) combined with high frequency and low amplitude to ensure precise classification.

Coarse particles (≥10mm): Use single-layer screens with large apertures (e.g., 20–50mm) paired with low frequency and high amplitude to improve processing efficiency.

Screen Width: Directly determines processing capacity. For every 10% increase in width, the production capacity increases by approximately 15%.

Screen Length: Affects screening precision. For every 20% increase in length, the screening efficiency (through-sieve rate) improves by about 20%.

Aspect Ratio Recommendation:

For general materials: 1:2 to 1:3 (e.g., 1000×2000mm).

For difficult-to-screen materials (e.g., ultra-fine powders): Can be increased to 1:4.

Amplitude:

For fine particles (e.g., flour): Use low amplitude (2–4 mm).

For coarse particles (e.g., ores): Use high amplitude (6–8 mm).

Adjustment is achieved by changing the angle between the eccentric blocks of the vibration motors.

Vibration Direction Angle:

Increasing the angle (e.g., from 45° to 60°) extends material residence time, improving precision.

Reducing the angle (e.g., to 30°) accelerates material flow speed.

Screen Surface Inclination:

For general materials (e.g., sand and gravel): Set inclination at 5°–8° to balance capacity and accuracy.

For sticky materials (e.g., wet coal): Inclination can be increased to 10°–15° to utilize gravity for auxiliary discharge.

Contact parts such as the screen box, screen mesh, and discharge outlet must be made of 304/316L stainless steel (to prevent rust contamination). The design must be dead-space-free (to avoid material residue and bacterial growth), allow quick disassembly of the screen mesh (for easy cleaning), and be equipped with food-grade silicone sealing strips (to prevent dust leakage or foreign matter ingress).

As the linear vibrating screen is a customized equipment, the exact lead time depends on your specific requirements and the customized production process. The estimated timeline will be provided after our technical engineers finalize the solution for your application. A dedicated sales representative will follow up and communicate updates in real time.

23 years of experience specializing in screening and conveying equipment manufacturing [Rich experience, providing complete customized solutions]

40,000 square meter factory, a genuine source manufacturer [No middlemen, lower prices]

50 technical patents, CE/ISO certifications [Technology proven, trustworthy]

20 years of export experience, equipment exported to over 70 countries worldwide [Full-process support from a professional team]

Ensure your product quality and reputation.

Our professional solutions are designed to maximize your production efficiency.

Reduce production downtime, resource waste, and maintenance issues.